6 Tips for Purchasing a Verifier

Compared to a standard barcode scanner, verifiers are more technically advanced devices and choosing an appropriate one for your needs requires some very specific concerns. Where a barcode scanner’s only goal is to simply read the barcode and transmit the embedded data, verifiers are analyzing and grading the actual print quality of the barcode. Most businesses never need to get into the nitty gritty of verification but for those that are distributing their products to other vendors like Walmart or the DOD there are heavy fines for sending barcodes that do not meet very requirements.

Compared to a standard barcode scanner, verifiers are more technically advanced devices and choosing an appropriate one for your needs requires some very specific concerns. Where a barcode scanner’s only goal is to simply read the barcode and transmit the embedded data, verifiers are analyzing and grading the actual print quality of the barcode. Most businesses never need to get into the nitty gritty of verification but for those that are distributing their products to other vendors like Walmart or the DOD there are heavy fines for sending barcodes that do not meet very requirements.

Verifiers not only are more technically advanced than regular scanners they also carry a much heftier price tag. These 6 tips will help guide you to a verifier that will meet your needs and get the most on your investment.

What barcode types or symbologies does the verifier test?

Every verifier should specifically state what types of barcodes it can work with. Don’t settle for an imprecise answer, like “all types†or “1D and 2D†barcodes. The specification for any verifier should explicity list what codes it can test for as well as their mil sizes. Making sure the type and size of code you are working with can be verified is a crucial first step.

What protocol does the verifier use to evaluate the symbologies?

The first part of this concern is knowing what protocol is required of you. Normally, the ISO or ANSI specification is suitable but some applications might require you to test to AIM specifications. In these cases, if your verification test isn’t specifically compliant to the AIM protocol, you may end up producing barcodes that don’t meet your customer’s requirements and incur fines or penalties.

Is the verifier itself compliant?

Most verifiers use the ISO or ANSI specification as the format for their reports, but not all verifiers are themselves compliant to the ISO specification that describes how the device is supposed to perform. Any verifier that itself is not ISO compliant is not one that should be trusted for any application use.

Does the barcode verifier require periodic re-calibration?

Most verifiers have calibration cards to ensure they are working properly over time. Some models will include this card while others require it as a separate purchase. There are also some models that require being sent back to the manufacturer for proper re-calibration. Depending on your needs and budget, how the unit can be re-calibrated should be a concern when choosing a device.

How does the barcode verifier report grade the tested symbols?

The most common grading method is a numerical ISO grading scale. Depending on your customer’s requirements though the ANSI letter grading system may be preferred. Ultimately, meeting the needs of your customer requirements should drive which grading scale you’ll need in from the verfier.

What is the verifier form factor?

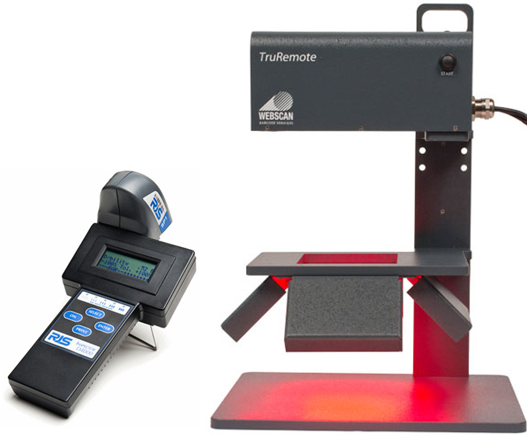

Verifiers often come in either portable or fixed/desktop models. In the case of a portable model, you’ll want to make sure there is a convenient way to transfer the collected data to PC for viewing, archiving, printing or emailing the results. With fixed models, you’ll need to make sure the interface is available on your PC and doesn’t interfere with your production process. Some fixed models can directly mount onto your label printer to verify every label as it is printed and even stop the printing process when the quality drops below a certain threshold. With these devices the main concern is having the right connectivity to match your printer brand and model.

Choosing a verifier is a task that shouldn’t be taken lightly but following a few key questions you can ensure you choose a device that will provide the accuracy and reliability that is required to make barcodes that meet any standard.