Barcoding News

Data tracking news, product updates, tips, and more

Unleashing Efficiency: The Power of Omni-Directional Barcode Scanners

In all aspects of business, it’s no surprise that efficiency is paramount. the ability to quickly and accurately scan barcodes is a fundamental component of streamlined operations, especially in the retail, warehousing, manufacturing, logistics, and healthcare industries. Omni-directional barcode scanners, with their ability to capture codes from any angle, have emerged as a game-changer in this regard. Keep reading for our review of the top four reasons to choose multi-faceted scanning technology, and why the Code Reader CR2100 is a top scanner choice for any industry.

What Makes Omni-Directional Barcode Scanners Better?

Unlike traditional linear barcode scanners that require precise alignment to capture the barcode, omni-directional barcode scanners can read barcodes in any orientation, thanks to a series of complex laser patterns or an array of cameras to capture barcode data from multiple angles. The following are key operational benefits to omni-directional scanners.

- Enhanced Efficiency and Speed. With no need for precise alignment between the scanner and the barcode, omni-directional scanners reduce the time it takes to scan items.

Ideal for: High-traffic environments, retail checkout counters, warehouses, assembly lines. - Improved Accuracy and Reduced Errors. Manual scanning errors can cripple supply chain operations, particularly inventory management and shipping processes. The enhanced scanning capability of omni-directional scanners significantly reduces incorrect scans – even from damaged or poorly printed barcodes.

Ideal for: Environments with large volumes of goods to be tracked quickly, healthcare, logistics. - Versatility in Scanning Multiple Barcode Types. Beyond traditional 1D barcodes, omni-directional scanners capture complex 2D barcodes that are quickly becoming essential for enhanced data encoding and security. The ability to seamlessly switch scanning type versus maintaining multiple scanners saves on hardware and support costs, plus improves operational flexibility.

Ideal for: retail stores, warehouses, manufacturing facilities, healthcare settings. - Durability and Reliability. Whether your barcodes are being scanned in a dusty environment or fast-paced locations, these scanners are typically designed for rugged use. Durability translates into lower operational costs over time, as businesses spend less on scanner maintenance and replacement.

Ideal for: warehouses, healthcare facilities, retail locations.

Product Review: The Code Reader CR2100 — A Standout in Omni-Directional Scanning

Now that you know the undeniable benefits to multi-faceted scanning, what is the best omni-directional barcode scanner? At Barcodes Inc., we offer a wide variety of barcode scanners to meet a variety of function and budget requirements. But when it comes to omni-directional technology, the Code Reader CR2100 is a stand-out for its superior speed, accuracy, and versatility in reading barcodes.

- Superior Scanning Performance. The CR2100 took unparalleled scanning performance and stepped it up a notch for tough scanning situations. With the CR2100, keep up with retail trends and accurately scan a barcode or QR code on a reflective mobile phone screen. In healthcare settings, it tackles even the most mangled medication packaging or patient wristbands.

- Ergonomic Design for Comfort and Efficiency. Lightweight and ergonomic in design, the Code Reader CR2100 ensures comfort even in retail or warehouse environments where workers need to scan hundreds or even thousands of items in a single shift. Users can quickly align the scanner with the barcode without wasting time on precise positioning. The scanner can be used in various modes, including handheld, hands-free, and fixed-mount configurations.

- Durability in Demanding Environments. A rugged construction with high IP ratings for protection against dust, moisture, and drops ensure long-term reliability and reducing downtime for repairs or replacements. Clean your device with confidence knowing the PVC-free CodeShield® plastics stand up to harsh chemical cleaners.

- Seamless Integration with Existing Systems. One of the key strengths of the CR2100 is its flexibility when it comes to integration. Whether your business uses point-of-sale systems, warehouse management software, or electronic health records systems, the CR2100 can easily integrate with these platforms, offering seamless data capture and transfer.

Conclusion

Omni-directional barcode scanners offer substantial operational benefits, including improved efficiency, accuracy, and versatility. By investing in omni-directional scanners, organizations can streamline their operations, reduce costs, and improve overall customer satisfaction. The Code Reader 2100 is a standout example of this technology, combining exceptional performance, durability, and flexibility to meet the needs of modern businesses.

At Barcodes Inc. we design our solutions and services around the customer first. Lean on Barcodes Inc. for fully managed device services and technology lifecycle support that provides a true end-to-end service solution.

Boost Your Warehouse Efficiency and Employee Satisfaction

Warehouse work is often physically demanding, requiring long hours, repetitive tasks, and enduring fluctuating temperatures. To better understand what contributes to job satisfaction and burnout in this crucial industry, Newcastle Systems conducted its first-ever Worker Satisfaction Survey, gathering insights from over 200 U.S. warehouse employees. The results provide a window into the challenges these workers face and what can be done to improve their work environment.

The Physical Demands of Warehouse Work

Many warehouse workers struggle with the intense physical requirements of their jobs. In the survey, 22.5% of workers said the physical demands caused significant fatigue, while 21% cited long hours as the main source of burnout. With 1.85 million people employed in the warehousing and storage sector across the U.S., these findings reflect the heavy toll this line of work can take on employees.

Do Warehouse Workers Feel Valued?

Employee morale is vital for an efficient warehouse, and feeling valued is key to job satisfaction. The survey revealed that while 39% of workers feel “somewhat valued,” 5% feel “not valued at all.” This highlights a clear opportunity for warehouse managers to focus on creating a work environment where employees feel appreciated.

Compensation plays a major role in satisfaction, with 33% of respondents pointing to fair and competitive pay as the most important factor. As labor shortages persist and eCommerce demands rise, employers must prioritize pay and working conditions to retain a dedicated workforce.

Addressing Workforce Needs: Tools and Equipment

A significant finding from the survey is the lack of adequate tools and equipment. Ten percent of respondents noted they lack the necessary tools to do their jobs effectively. This concern extends to critical areas like safety equipment, warehouse automation, and heating and cooling systems.

To improve worker satisfaction and efficiency, employers must invest in modernizing equipment, upgrading safety protocols, and improving environmental controls. These investments can enhance productivity and morale while creating a safer, more comfortable work environment.

Embracing Technology and Ergonomics

The survey shows that warehouse workers are generally open to new technology, particularly if it improves efficiency and reduces physical strain. Many respondents expressed moderate comfort with the idea of integrating robotics into operations. This openness presents a valuable opportunity for employers to introduce ergonomic solutions such as mobile-powered workstations, wearable barcode scanners, and collaborative robots (cobots).

Ergonomic tools were especially praised for their positive impact on job enjoyment. While automation is important, it’s clear that ergonomic solutions, which reduce physical strain, resonate strongly with workers and can significantly boost productivity.

20% of respondents expressed that ergonomic and productivity tools (like mobile-powered workstations and wearable barcode scanners) make their jobs more enjoyable, suggesting that small technological enhancements can significantly impact worker satisfaction.

The Benefits of Ergonomic Workstations

Mobile-powered workstations are one of the most effective solutions for bridging the gap between manual labor and automation. These workstations enhance efficiency without the complexity of full-scale robotic systems. By simplifying tasks and reducing physical demands, they offer a practical solution to improve both productivity and employee satisfaction.

The survey also highlighted generational differences in what workers value most. Younger employees (ages 18-25) prioritize workplace safety, growth opportunities, and leadership style. Workers aged 26-40 emphasize fair pay, growth opportunities, and work/life balance, while older workers (41+) focus on work/life balance and competitive pay.

Maximizing Employee ROI

To maximize the return on investment (ROI) in their workforce, warehouse managers should focus on key areas: compensation, ergonomic tools, and supportive work environments. Enhanced pay packages, engaging incentive programs, and improved communication can go a long way in increasing worker satisfaction and loyalty. Addressing environmental concerns, such as temperature control, also plays a significant role in improving well-being.

Conclusion: Investing in Warehouse Workers

Warehouse workers are essential to the success of the logistics and eCommerce industries. The Newcastle Systems Worker Satisfaction Survey reveals that fair compensation, better tools, and improved working conditions are crucial to maintaining a happy and productive workforce.

Contact us today to learn how Newcastle Systems’ purpose-built mobile power workstations enhance on-floor productivity, allowing workers to focus on value-added tasks. This approach not only boosts efficiency but also enhances the working experience, delivered through a team of people vested in business success and worker happiness.

The Impact of iOS in Retail

Barcode scanning challenges have long hindered retail efficiency, often slowing down operations and frustrating employees. Modern barcode scanning apps on iOS devices frequently struggle with speed, accuracy, and handling damaged barcodes. However, integrating sleds with iOS devices offers a promising solution to these issues. With trends indicating significant investments in retail technology to enhance efficiency and employee satisfaction, advanced solutions like iOS sleds are critical for meeting retail demands and driving productivity.

The evolution of mobile technology in retail has been driven by the urgent need for rapid, high-quality customer service, especially amid persistent labor shortages. While basic handheld barcode scanners and POS systems streamlined some operations, they failed to meet the needs of mobile POS systems, inventory management, and real-time data access. To stay competitive in this fast-paced industry, retailers have begun leveraging iOS for efficient, secure operations that elevate retail capabilities and customer engagement.

The Future of iOS in Retail

Future trends in iOS are set to significantly impact the retail industry by enhancing operational efficiency and boosting employee satisfaction. According to a Scandit study, 41% of workers believe that user-friendly technology is crucial for fostering workplace loyalty, with iOS’s intuitive design being a key advantage. Additionally, over two-thirds of store associates globally rate their devices as important or very important for their jobs, indicating that the adoption of iOS solutions can enhance productivity and engagement. Gartner predicts global retail spending on technology will reach $262.6 billion by 2027, showcasing the strong investment in iOS solutions for inventory management, mobile POS systems, and personalized customer interactions. This surge in technology investment is likely to boost employee satisfaction and operational performance across the retail sector.

The Challenges of Barcode Scanning on iOS Devices

Despite the advantages of iOS in retail, barcode scanning on these devices presents several challenges, such as:

- Speed & Accuracy

- Field-of-View & Distance Reaches

- Inability to Read Damaged Barcodes

Additionally, iPhones lack side trigger buttons, essential for expediting tasks like restocking, and require users to rely on the screen to ensure the barcode is within view.

Enhancing iOS with Mobile Phone Sleds

Mobile phone sleds significantly improve efficiency and accuracy in retail environments by providing physical trigger buttons and advanced scanning capabilities. According to Zebra’s comparative analysis, using an integrated scan engine with a physical trigger button saves workers 41.36 minutes per day compared to using a consumer device with a camera and virtual button. This 30% time savings allows associates to be repurposed for other tasks, increasing picking and fulfillment scans.

With the demand for a swift upgrade to existing iOS devices, mobile device sleds that transform iPhones into enterprise-ready tools are more essential than ever. These sleds provide instant usability, efficient operation, and quick scanning of both linear and 2D barcodes, meeting the high demands of retail environments and boosting productivity.

The Barcodes, Inc Advantage

Barcode scanning challenges have long hindered retail efficiency, but integrating mobile phone sleds with iOS devices offers a robust solution. These sleds enhance scanning by offering physical trigger buttons, dedicated scanners with longer reach, and the ability to scan barcodes without viewing the screen. This has proven to save workers time and energy, allowing them to focus on higher-value tasks and boosting overall productivity.

If you’re ready to enhance your retail operations and improve efficiency, Barcodes, Inc is here to help. Our team specializes in integrating enterprise mobility solutions that transform your iOS devices into powerful, enterprise-ready tools. From streamlining barcode scanning to increasing productivity and customer satisfaction, we’re committed to providing the technology and support you need. Contact us today to get started!

From Challenges to Triumph: Yamaha G3 Boats’ RFID Journey

When Yamaha G3 Boats faced challenges with visibility, efficiency, and tracking in their production process, they turned to Barcodes, Inc to implement an RFID solution. This strategic move aimed to increase production capacity and streamline operations, ultimately paving the way for significant growth and improved productivity. Their success was recognized with the ‘Best Manufacturing Implementation of RFID’ award at the 2024 RFID Journal Live, demonstrating the impact of advanced technology in overcoming operational bottlenecks.

About Yamaha

Yamaha G3 Boats is renowned for producing high-quality aluminum fishing boats and recreational pontoon boats. With a strong commitment to craftsmanship and innovation, they’ve earned a reputation for delivering durable and reliable vessels. Their product range caters to both avid anglers and recreational boaters, offering top-notch performance and comfort on the water. Yamaha G3 Boats is also known for their continuous improvement initiatives, consistently integrating advanced technologies to enhance both manufacturing processes and product offerings.

Barcodes, Inc Advantage

To tackle the challenges of visibility, efficiency, and tracking in their manufacturing process, Yamaha turned to Barcodes, Inc’s cutting-edge RFID systems, which delivered an ideal solution. By deploying RFID technology, Yamaha was able to:

- Enhance Visibility: Barcodes, Inc’s RFID technology provides real-time visibility into the production line. RFID tags attached to each boat and key components allow Yamaha to track their location and status at every stage of production. This real-time data enables the company to quickly identify and resolve issues, ensuring smoother production processes.

- Improve Efficiency: With comprehensive tracking capabilities, RFID technology optimizes workflow on the shop floor. Identifying bottlenecks and streamlining operations allows Yamaha to meet production schedules more accurately and efficiently. Additionally, automated data entry and ERP system integration further boost operational efficiency.

- Accurate Tracking: RFID tags enable precise tracking of each boat throughout the manufacturing process. This accuracy minimizes errors and improves resource allocation. Real-time tracking of every component and work order ensures production stays on schedule, leading to improved throughput.

Looking Ahead

Yamaha G3 Boats continues to expand its RFID capabilities with future phases planned. By partnering with Barcodes, Inc, Yamaha remains poised to meet market demands and maintain their competitive edge.

The success of Yamaha G3’s RFID implementation is a milestone for Barcodes, Inc, and we look forward to continuing this partnership to achieve even greater accomplishments. Congratulations to everyone involved in this project!

Boosting Efficiency in Packaging: The Power of Print and Apply Technology

In today’s fast-paced manufacturing and packaging industries, manual processes and rising labor costs can significantly hinder efficiency and increase operational expenses. Traditional methods of applying labels and printing product information on unfolded boxes require considerable manpower, leading to both higher labor costs and a greater potential for human error. Barcodes, Inc’s Print and Apply solution tackles these challenges head-on, offering an advanced system that automates and streamlines these crucial tasks.

What is Print and Apply?

Print and Apply technology automates the labeling and printing process on unfolded boxes. Traditionally, these tasks required manual effort, but Barcodes, Inc’s solution incorporates a sophisticated, AI-powered system that not only enhances speed but also ensures greater accuracy, boosting production efficiency across the board.

How It Works

- Preparing Boxes: Boxes ranging from 4×4 inches to 40×60 inches are automatically separated for labeling.

- Labeling or Printing: Depending on the print job, the system applies labels using a labeler with a print engine or directly prints product information onto the boxes with an inkjet system.

- Inspection: An AI-powered system inspects each box to verify correct application of labels or printed data. This step ensures accuracy, eliminates production errors, and only allows correctly labeled or printed boxes to proceed.

- Restacking: Labeled or printed boxes are moved to an automatic restacking bin, ready for transport to their designated locations.

Benefits of Barcodes, Inc’s Print and Apply

- Increased Production Rates: Automating the labeling and printing process accelerates production lines, resulting in higher output and enhanced efficiency.

- Reduced Labor Costs: Automation minimizes the need for manual labor, cutting labor expenses and allowing businesses to allocate resources more effectively.

- Enhanced Accuracy: AI-powered inspections prevent production errors, ensuring only correctly labeled or printed boxes move forward, reducing costly mistakes.

- Versatility: The system accommodates a wide range of box sizes without requiring manual adjustments, providing flexibility for various packaging needs.

- Quality Assurance: Motorized guides ensure the precise positioning of labels and printed information, further reducing the likelihood of errors.

Applications Across Industries

- Packaging: Automates labeling and printing processes, improving efficiency and reducing errors.

- Pharmaceuticals: Ensures accurate labeling for regulatory compliance and product safety.

- Food and Beverage: Manages diverse packaging needs with speed and accuracy, maintaining high-quality standards.

- Warehousing: Facilitates efficient inventory processing, improving overall warehouse operations.

By implementing Barcodes, Inc’s Print and Apply system, companies can overcome the challenges associated with manual processes and rising labor costs, leading to improved production efficiency, cost savings, and enhanced product quality. This innovative technology not only meets the demands of today’s dynamic industries but also lays a strong foundation for future growth and innovation.

From Farm to Fork: Ensuring Food Safety with Effective Labeling

Food safety is a top priority for everyone involved in the food supply chain, from farmers and manufacturers to distributors, retailers, and ultimately, consumers. Contaminated food can cause serious illness, and preventing these outbreaks requires a multi-pronged approach. One critical element in this strategy is effective food safety labeling. The best food label printers are designed to meet the specific requirements of the food industry, offering advanced features that enhance food safety practices. Read further to learn the importance technology plays in ensuring accurate and efficient labeling practices.

Why Food Safety Labeling Matters

Food safety labeling plays a crucial role in safeguarding consumers from potential hazards. It allows for accurate tracking of food products throughout the supply chain, facilitating swift and targeted action in case of recalls or contamination concerns. Clear and consistent labeling also empowers consumers to make informed choices about the food they eat.

Here are some specific ways food safety labeling contributes to a safer food system:

- Traceability: Labels with essential information like batch numbers, expiration dates, and processing facilities enable tracing in the event of recalls.

- Allergen Awareness: Clear and accurate allergen labeling on food packaging allows consumers with allergies to make safe choices.

- Ingredient Transparency: Detailed ingredient lists on labels help customers with specific dietary needs or preferences make informed choices.

- Best-Before Dates: Best-before dates advise consumers when food maintains its optimal quality and safety.

- Instructions and Warnings: Labels can include instructions for proper handling, storage, and preparation of food.

Technology’s Role in Food Safety Labeling Accuracy and Efficiency

Label printer technology plays a vital role in ensuring the accuracy and efficiency of food safety. As North America’s leading provider of barcode and product labeling, mobile computing, and RFID solutions, Barcodes Inc. partners with the most trusted brands in the food service and grocery industry that offer unique food labeling features.

- Digital Printing Solutions: Advanced digital printing technologies facilitate on-demand printing of labels, allowing for real-time updates and increased flexibility. This reduces waste and ensures the most recent information is included on labels.

- Variable Data Printing: This technology allows for printing unique information like lot codes and expiration dates on each individual label, enhancing traceability and facilitating targeted recalls if needed.

- Label Management Software: Centralized software solutions streamline the creation, approval, and printing of food safety labels, fostering consistency and reducing errors.

- RFID (Radio Frequency Identification) Technology: RFID tags embedded in food packaging offer enhanced traceability as they can track food products throughout the supply chain in real-time.

SATO: Empowering Businesses with Food Safety Labeling Solutions

Not all label printers are created equal. SATO food safety label printers are a top-shelf choice in the food and grocery industry for their durability, resistance to moisture and temperature fluctuations, and crisp, clear label printing. Here are a few reasons SATO printers remain a top choice for food manufacturers and retailers:

Improved Efficiency: High-speed printing and easy integration with existing systems streamline labeling processes, reducing bottlenecks and improving overall productivity.

Enhanced Traceability: Accurate and legible labels facilitate effective tracking of food products throughout the supply chain, ensuring compliance with regulatory requirements.

Durability and Reliability: SATO printers are built to withstand tough conditions, ensuring uninterrupted operation in food production environments.

Versatility: The printers can accommodate a wide range of label materials and printing applications, meeting the diverse needs of the food industry.

SATO is the innovator behind DateRight™ Rotation Labeling, a solution to streamline food storage and rotation in food service outlets. The label incorporates seven color indicators that represent the days of the week, allowing for easy visual identification of expiring products and promoting FIFO (First-In, First-Out) inventory management.

Let’s explore two popular food label printer models by SATO, the CL4NX Plus and CT4-LX printers.

SATO CL4NX Plus RFID Label Printer:

High-Speed Printing: The CL4NX Plus delivers rapid printing speeds up to 10 ips, reducing labeling bottlenecks and improving overall production efficiency.

UHF RFID Module: Print text and barcodes on UHF tags/labels and encode data in their embedded chips at the same time. The CL4NX Plus is even capable of checking RFID chips prior to encoding to verify their readiness to use and to prevent failures.

Flexible Media Handling: The printer can accommodate a wide range of label materials, including those with special coatings or adhesives, ensuring compatibility with various food packaging applications.

Advanced Connectivity Options: The CL4NX Plus offers seamless integration with existing systems, enabling efficient data transfer and label printing.

Learn more about the SATO CL4NX Plus.

SATO CT4-LX Label Printer:

- Compact and Portable: The CT4-LX is a 4-inch compact and portable printer, making it ideal for mobile labeling applications in food production facilities.

- Patented Label Waste Prevention: SATO’s patented label waste prevention feature helps minimize label waste, contributing to cost savings and environmental sustainability.

- High-Resolution Printing: The printer delivers clear and legible labels, ensuring accurate product information and traceability.

- Wireless Connectivity: The CT4-LX offers wireless connectivity options, enabling mobile workers to print labels from remote locations.

Learn more about the SATO CT4-LX.

By incorporating high-quality food label printers like the SATO CL4NX Plus RFID and CT4-LX printers into their operations, businesses can enhance food safety labeling practices, improve efficiency, and ensure compliance with regulatory standards. Barcodes, Inc. is a leader in supply chain solutions, offering high-quality thermal printers and compatible labels specifically designed for unique industries. For help finding the right labeling solutions for your business, contact Barcodes Inc. today.

Mobile Devices Revolutionizing Retail & Manufacturing

Enterprise mobility has rapidly evolved, driven by technological advancements and changing business needs. Organizations are increasingly embracing mobile solutions to streamline operations, enhance productivity, and improve customer experiences. Thanks to strong relationships with partners who share a passion for innovative technology trends in modern environments, Barcodes Inc. can share insights on the best mobile devices for retail and manufacturing industry operations.

Unitech’s Android-powered mobile tablet RT112 and EA660 rugged handheld computer are leading the charge in the mobility transformation. These ultra-portable devices offer the durability, flexibility, and functionality needed to meet the challenges of modern retail and manufacturing environments. With 1D/2D scanning that enables barcode reading at distances of up to 10m (12m for the EA660 smartphone) with 5G and Wi-Fi 6E connectivity, users capture real-time data collection that instantly connects to backend systems that confirm in-stock quantities or process online customer orders. From the rigors of retail to the harsh elements introduced on the manufacturing floor, the versatility and durability of Unitech mobile computing devices deliver the performance retail and manufacturing businesses need.

A Rugged Mobile Tablet Built for Demanding Use

When it comes to mobile devices designed for efficiency and reliability, the Unitech RT112 rugged mobile tablet won’t disappoint. Its durable construction with IP67 protection and drop test resilience up to 1.5 meters earned it MIL-STD810H certification. It is uniquely designed for field service and industries such as manufacturing and retail.

Retail Applications:

- Inventory Management: Real-time stock tracking, cycle counting, and price audits can be efficiently performed using the RT112. Its large 10.1-inch display and intuitive interface facilitate quick data entry and retrieval.

- Point of Sale (POS): By integrating the RT112 with POS software, retail store employees are empowered to streamline checkout processes and reduce wait times on the shop floor with the ability and take payments anywhere.

- Customer Service: Equipped with barcode scanning capabilities, the RT112 can quickly access product information, check inventory levels, and process returns, improving overall customer service.

Manufacturing Applications:

- Warehouse Management: The RT112 can be used for tasks such as picking, packing, shipping, and improving order accuracy and efficiency. Its data capture capabilities ensure seamless integration with warehouse management systems.

- Quality Control: Inspection processes can be streamlined with the RT112, allowing for real-time data collection and analysis. Its rugged design enables it to withstand harsh manufacturing environments.

- Asset Management: Tracking and managing assets is simplified with the RT112. Its barcode scanning functionality and data collection capabilities ensure accurate asset information.

A Compact, Rugged Handheld Smartphone Mobile Workers Will Love

The Unitech EA660 rugged smartphone with 6-inch display is a powerful solution with similar functionality to its mobile tablet counterpart. It offers an even more compact solution for mobile workers in retail and manufacturing, enhanced by an ergonomic design and durable build that lends well to various applications.

Retail Applications:

- Mobile Sales: Sales associates can access product information, pricing, and inventory levels on the go, enhancing customer engagement and closing deals faster.

- Price Checks: The EA660 can be used to quickly verify product prices, preventing errors and improving customer satisfaction.

- Loss Prevention: Equipped with advanced data capture capabilities, the EA660 can assist in loss prevention efforts by tracking inventory and identifying discrepancies.

Manufacturing Applications:

- Work Order Management: Mobile workers can access work orders, update progress, and capture data on the EA660, improving operational efficiency.

- Maintenance Management: Field service technicians can use the EA660 to access equipment information, troubleshoot issues, and schedule repairs.

- Supply Chain Management: The EA660 can be used to track shipments, manage inventory, and optimize logistics operations.

- Safety and Compliance: push-to-talk capabilities offer critical communication in emergencies, and safety applications monitor environmental conditions and alert workers to hazards.

Mobile Devices: The Backbone of Retail and Manufacturing Success

As the retail and manufacturing industries continue to evolve, the role of durable, high-performance mobile devices will only become more critical in driving success and innovation. In retail, mobility devices streamline inventory management, improve customer service, and offer flexible POS solutions. In manufacturing, rugged tablets and handheld computers deliver the durability, reliability, and functionality required to manage workflows, collect data, and ensure safety in challenging environments.

If you’re interested in exploring the Unitech RT112 tablet or EA660 handheld mobile computer, plus other mobile solutions from Barcodes Inc., contact us today.

Modernizing Manufacturing: Leveraging Mobile Technology for a Smart Factory Transformation

The manufacturing industry is undergoing a digital transformation, driven by the need for increased efficiency, productivity, and quality. The transition towards modernized manufacturing is not just a trend, but a necessity for manufacturers aiming to stay competitive. At the heart of this revolution lies the adoption of advanced technologies, including rugged tablets designed to withstand the demanding conditions of the factory floor. As an industry leader in modern mobility-enabled environments, Barcodes Inc. understands the pivotal role that mobile tablets like the Samsung Galaxy Tab Active5 contribute to accelerating the smart factory transformation.

Understanding the Smart Factory Concept

A smart factory represents the pinnacle of manufacturing modernization, where advanced technologies, cloud computing, and artificial intelligence (AI) converge to create a highly connected and automated production environment. These factories ensure continuous improvement and optimization.

A recent report by CapGemini underscores the potential benefits of smart factories, noting that early adopters have already realized a 20 percent gain in production. The report also predicted significant improvements in on-time delivery, productivity, and labor rates in the coming years.

The Role of Mobile Technology in Manufacturing Modernization

Mobile technology, like rugged mobile tablets, serves as the linchpin for modernizing manufacturing operations. These devices connect staff to essential business applications, distribute intelligence and insights across the production floor, and facilitate real-time data processing. Here’s how mobile tablets like the Samsung Galaxy Tab Active5 can be leveraged to drive smart factory initiatives:

Built for the Factory Floor

The Samsung Tab Active5 is engineered to excel in the harsh environments prevalent in manufacturing facilities. Its rugged design, featuring IP68 water and dust resistance as well as MIL-STD-810H certification, ensures durability and reliability even in the toughest conditions. Whether it’s exposure to liquids, dust particles, or accidental drops, this tablet can withstand the rigors of the manufacturing floor without compromising performance.

Enhancing Productivity and Efficiency

One of the most significant advantages of the Samsung Tab Active5 is its ability to boost productivity and efficiency. By equipping frontline workers with this mobile device, manufacturers can streamline various processes, from quality control and inventory management to maintenance and repair. For example, quality control inspectors can use the Galaxy Tab Active5 to capture high-resolution images and videos of product defects, facilitating root cause analysis and corrective actions. Maintenance technicians can access digital work instructions and maintenance records, enabling them to troubleshoot issues more efficiently and minimize downtime. Additionally, the tablet’s ability to support barcode scanning and RFID technology can accelerate inventory management processes and reduce errors.

Improving Data Collection and Analysis

In today’s data-driven manufacturing environment, the ability to collect and analyze real-time data is essential for optimizing operations. The Samsung Tab Active5 excels in this area, providing manufacturers with a powerful tool for data capture and analysis. Its integrated cameras, sensors, and connectivity options allow for the collection of a wide range of data, including production metrics, equipment performance, and environmental conditions. This data can be used to identify bottlenecks, optimize workflows, and improve overall plant performance.

Enhancing Collaboration and Communication

Effective communication and collaboration are crucial for successful manufacturing operations. The Samsung Tab Active5 facilitates seamless communication between team members, regardless of their location within the facility. With features like video conferencing and instant messaging, employees can easily share information, coordinate tasks, and resolve issues in real time. By breaking down communication silos, manufacturers can improve teamwork and responsiveness, leading to increased efficiency and productivity.

The Future of Manufacturing with Mobile Technology

Utilizing rugged tablets for modern manufacturing is filled with opportunities. Manufacturers can streamline operations, boost productivity, and maintain high-quality results that lead to increased efficiency and profitability. Equally important, the integration of mobile technology like the Samsung Galaxy Tab Active5 empowers your workforce to access information and tools that create a more engaged and skilled workforce.

If you’re interested in exploring the Samsung Galaxy Tab Active5 further, or if you have any questions about modernizing your manufacturing floor, feel free to contact Barcodes Inc. Our team is here to help you find the perfect mobile computing solutions for your business.

Grow Your Business With Enhanced Shipping Labels

In the dynamic world of retail and ecommerce, product packaging is more than just a container, it’s a crucial element of your brand’s identity and a powerful tool for attracting and retaining customers. With increasing competition and discerning consumers, businesses need to take advantage of every opportunity to increase customer engagement. Enter Epson Label Boost software, a revolutionary tool designed to transform the way you create and manage labels, ensuring your products not only stand out but also convey the right message to your customers. Paired with Barcodes Inc. color label printers and labeling supplies, Label Boost reimagines the possibilities for shipping labels.

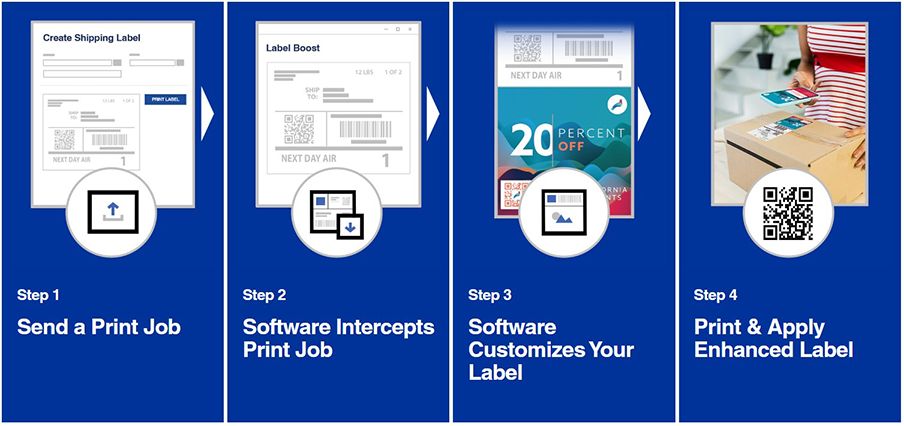

How Do Integrated Secondary Labels Work?

Integrated labels transform your existing black-and-white shipping labels by adding vibrant, full-color elements such as coupons, targeted ads, and secondary labels for regulatory or shipping-and-handling information. You can also emphasize critical details, like parcel count or expedited shipping, to ensure accuracy and prompt delivery.

Epson Label Boost is a software solution designed for effortless integration. It allows you to keep the bulk of your label creation process unchanged, making modifications only at the final step before printing. This software works seamlessly with your existing shipping software, ensuring uninterrupted delivery operations. Label Boost is compatible with most Epson ColorWorks® printers, guaranteeing that your labels are printed with exceptional image quality that enhances your brand.

Benefits of Integrated Messaging on Shipping Labels

1. Better Brand Image

A cohesive and attractive brand image is vital. With label-enhancing software like Epson Label Boost, businesses can design labels that are consistent with their brand’s aesthetics, ensuring that every product looks professional and aligned with the overall brand strategy.

2. Grow Sales & Customer Retention

Boost sales and customer retention by incorporating marketing messages and promotions on shipping labels, transforming each package into a dynamic touchpoint that engages customers and incentivizes repeat purchases.

3. Increased Workflow Efficiency

Simplifying your label printing processes will save you time and resources. By printing shipping details, critical shipping notices, and marketing promotions all on one label, you’ll cut manual data entry, reduce chances for mistakes, decrease workflow steps, and reduce labeling supplies.

4. Cost-Effective Printing

The ability to produce high-quality labels in-house reduces the need for outsourcing, resulting in cost savings. Additionally, the software’s efficiency and integration capabilities mean lower labor costs and increased productivity.

5. Targeted Campaigns with Customization & Personalization

Consumers appreciate products that feel tailored to them. With Epson Label Boost, businesses can easily produce customized labels for special promotions, seasonal products, or personalized marketing campaigns. This level of customization helps to engage customers and build brand loyalty.

6. Compliance and Accuracy

For industries with stringent labeling requirements, such as food and pharmaceuticals, Epson Label Boost ensures that all necessary information is accurately presented. This helps in meeting regulatory standards and avoiding costly compliance issues.

Start Elevating Your Brand Today

At Barcodes Inc., we’re more than a label printer and supplies provider, we’re an end-to-end supply chain and enterprise mobility services leader. Through our partnership with Epson, we’re proud to offer Label Boost as an integrated shipping label software solution that offers our customers a comprehensive tool that can elevate your brand, streamline your processes, and save you money. Whether you’re a small business or a large enterprise, Epson Label Boost provides the tools you need to create professional, high-quality labels that make a lasting impression.

Contact Barcodes Inc. today to learn more about how to improve brand identity, product visibility, customer retention, and compliance.