A Guide to Smart Printing

Understanding the Capabilities, Use Cases and Advantages of Smart Printers

Understanding the Capabilities, Use Cases and Advantages of Smart Printers

Businesses are continually looking for ways to work smarter. Printing operations provide an excellent – and often overlooked – opportunity. One growing trend among companies with bar code printing operations is to leverage the capabilities of “smart” printers, which are printers that integrate the power of a personal computer. Smart printers enable businesses to change the way their printing operations are structured, to streamline and improve processes in ways that reduce operating costs while improving reliability.

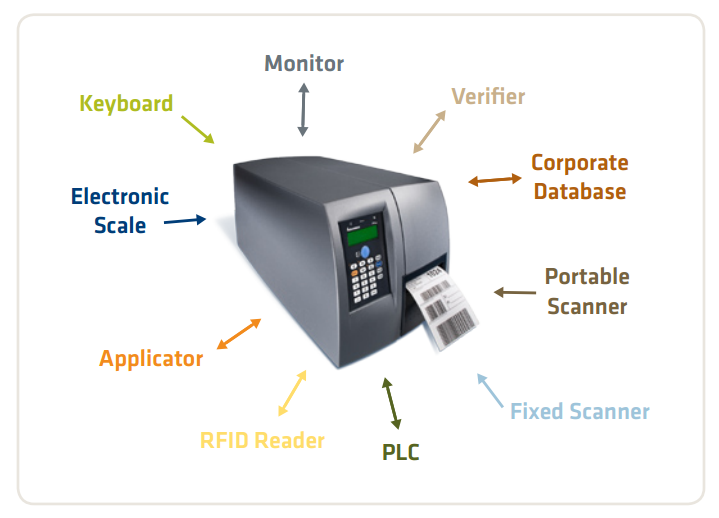

Smart printing takes advantage of the memory and processing power available in advanced printers to run printing operations independently, without a PC or network connection to another host computer. Smart printers can run software applications and can function as PLCs to control other devices, including scales, scanners and label applicators. By using the computing power that’s in the printer, organizations can reduce their IT hardware, networking and support requirements, lower the total cost of printing operations, and create work processes that improve productivity and reduce opportunities for errors.

Smart Printing Defined

Many printers have control panels and LCDs, but this does not make them smart. Smart printers are programmable and able to execute print jobs independently, without being controlled by a PC or other device. Programmability is the main feature that sets smart printers apart from other models.

Smart printers also typically have more onboard memory than computer-dependent printers, an LCD screen for prompts and user input, function keys, strong processors capable of doing much more than producing basic receipts and labels, and can connect to keyboards and other input devices. Smart printing capabilities have recently become available in mobile printers, after previously only being available in some stationary models.

The ability for the printer to run applications unlocks multiple possibilities. These include the ability to:

- Operate independently of a computer;

- Maintain databases (e.g. product codes, unit prices, customer ID numbers) and automatically include the information in the printed output;

- Execute payment and other transactions;

- Connect to scales, bar code scanners and other peripherals;

- Format variable data input into information on a printed label, receipt or document;

- Operate in mobile environments where there is no access to wireless networks or host devices;

- Serve as a controller for peripheral devices;

- Perform self diagnostics and troubleshooting.

A printer’s ability to be programmed and run applications independent of a host computer provide many of the advantages to smart printing – namely a simplified system architecture and lower TCO because there are no additional PCs and cables to install and maintain. Some smart printers also provide software connectivity options to enterprise systems that eliminate the need for middleware or custom interface development.

Self-management features are another valuable characteristic of smart printers. These include the ability to monitor print quality, automatically adjust bar code position to accommodate a failing printhead, and provide troubleshooting instructions to the operator when self-correction is not possible. These features increase uptime and make smart printers suitable for high-volume automated environments where downtime must be minimized to maintain productivity. Printers that are compatible with enterprise device management systems are valuable assets in these environments.

The following sections describe how organizations are taking advantage of these features to improve processes and reduce costs in enterprise operations.

Smart Printing Use Cases

Because smart printers are programmable and can operate without a computer or network connection, they provide tremendous flexibility in where they can be placed and how they can be used. Using the printer as a controller or programmable logic controller (PLC) eliminates the need for operators to trigger label requests or other actions, and therefore reduces the opportunity for operator error. Industrial smart printers can be installed in harsh environments where PCs can’t, while mobile models can bring new intelligence and hardware independence to workers in the field. As a result, organizations can optimize their business processes and logically integrate printing into operations, rather than treating it as a separate, inefficient step.

Smart printers are typically used to create output on demand exactly where it is needed. Printing at the point of need helps organizations avoid inefficient batch printing processes that greatly reduce the chance that a label will be applied to the wrong item or a document will be sent to the wrong place. Smart printers are also space savers that can replace a PLC (and the associated costs) to control other devices incrowded work areas. Some of the most popular and productive uses for smart printers are described briefly below.

On-demand output – Users can print shipping labels, merchandise tags, receipts, shelf labels, work orders, invoices and other output on demand by using the keypad to select the required format and quantity to output. Printing is fast because all processing happens in the printer without relying on network or other host connections.

Case in point: the pharmacy at a Midwest hospital connected a smart printer to its robotic drug dispensing machine to automatically create a bar code and text label for every drug and IV bag mixture released. The system prevents pharmacy labeling errors and supports the hospital’s automated medication administration system for improving patient safety, which helps ensure each patient receives the correct drugs and dosage.

Customer service & transaction processing – Businesses can create a variety of mobile service and line busting applications now that smart printing capabilities are available in mobile printers. The printer serves as a portable POS station by interfacing to a scanner to record customer purchases and using an integrated card reader to accept payment, which can be authorized over a PCI-compliant secure wireless connection. Smart mobile printers can also be used for event ticketing, claim checks, returns authorization and much more.

Scale interface – Using a serial port, USB, Bluetooth or network connection, smart printers receive input directly from weight and counting scales and include the variable data on label output. This capability is used to include carton weights on shipping labels, create ingredient labels and materials lists, produce price labels for products sold by weight and more. See the sidebar for an example.

Shipment verification and label generation– Workers use a bar code scanner or RFID reader interfaced to the printer to identify each item being packed into a shipping container. An application within the printer verifies each item belongs in the shipment by comparing the scanned ID to the shipment record stored in the printer. Only when all items required for the shipment have been packed will the printer produce a shipping label. The label can contain a two-dimensional bar code encoded with the individual ID numbers or product codes of all items packed inside.

Webasto Roof System credits such a system with helping it attain 100 percent shipment accuracy, which eliminated $190,000 in annual expenses related to shipment error resolution. Webasto manufactures sunroofs and must ship them to automakers in an exact sequence to support just-in-time production. Webasto previously manually inspected its products at three separate points, but still made sequencing errors that could lead to fines from its customers. Now when each sunroof passes the quality control inspection it receives a bar code label with a unique ID number. Then the sunroof is loaded into a rack that is used for shipping final products to customers. When the rack is filled, a clerk scans the bar code label for each sunroof in the order in which it is loaded on the rack. The bar code scanner is interfaced to a smart printer, which holds the customer order and sequence requirement in an onboard database. If all the sunroofs on the rack belong to the order, and they have been loaded in the correct sequence, the printer automatically generates a shipping label. If not, it alerts the operator.

Invoice and forms printing – A delivery driver or field service technician follows prompts on the LCD screen of a mobile printer to enter activity codes (e.g. “left package on porch” or “changedfilter”) for service performed at the work site. The mobile printer can then create an accurate, up-to-date work order, receipt or invoice on site, which saves the organization the time and effort of printing and mailing the documentation later from headquarters.

Computer-free printing– A convenience store chain takes advantage of smart printing to keep its sandwich label and pricing files up to date. Sandwiches are made fresh in each store each day, with sandwich types, ingredients lists and prices frequently changing. The store previously printed its sandwich labels in batches, but many were wasted because pricing or ingredients changes made the labels unusable. Now the chain downloads the next day’s sandwich prices and label formats to in-store smart printers each night. Labels are produced on demand as each sandwich is made, eliminating the waste that resulted from preprinted labels. Because the smart printer has onboard memory and can run applications, the crowded stores do not need to make room for another computer and the chain can benefit from consistent, up-to-date labeling and pricing practices across all franchise locations.

Process control – Smart printers not only control printing processes, but the peripherals or devices that work with them. Smart printers communicate with sensors, applicators and material handling control systems to synchronize printing operations. For example, a sensor that detects a box on a conveyor signals the printer to produce the required label, and the printer then directs an applicator to apply the label to the appropriate box, again using input from sensors on the conveyor line. The printer then triggers a green light on a light pole indicating that the labeled box is ready for pickup.

Thyssenkrupp Budd, a automotive supplier, error-proofed its labeling processes by connecting smart printers directly to partmaking machines. Its cradle-to-grave tracking system begins when the part-making machine sends a signal to a smart printer when a part is completed. The printer automatically generates the unique ID label that is then applied to the part. The process is even more accurate than having an operator request labels on demand, because no key entry or other manual input is required.

These are some of the many ways smart printing supports efficient processes, which in turn drive cost savings and productivity benefits. A smart printing infrastructure also saves up-front and ongoing support and maintenance costs, creating a highly favorable total cost of ownership (TCO) compared to common printer systems.

TCO Advantages of Smart Printing

A smart printing architecture keeps costs out of printer implementations and provides ongoing, sustainable benefits at each stage of the lifecycle: development, deployment, support and upgrade. Smart printing provides scalability, which allows enterprises to change printing processes without replacing their printers.

From the first day they are deployed, smart printers provide an immediate cost advantage over traditional implementations. Organizations can substantially lower their cost structure for printing operations by using smart printing to eliminate the PCs, cabling and network cards used to direct printing from a computer. Organizations can also eliminate the print server layer of their printing architecture and the associated software licensing and support costs by taking advantage of smart printers’ ability to interface directly with enterprise applications.

From the first day they are deployed, smart printers provide an immediate cost advantage over traditional implementations. Organizations can substantially lower their cost structure for printing operations by using smart printing to eliminate the PCs, cabling and network cards used to direct printing from a computer. Organizations can also eliminate the print server layer of their printing architecture and the associated software licensing and support costs by taking advantage of smart printers’ ability to interface directly with enterprise applications.

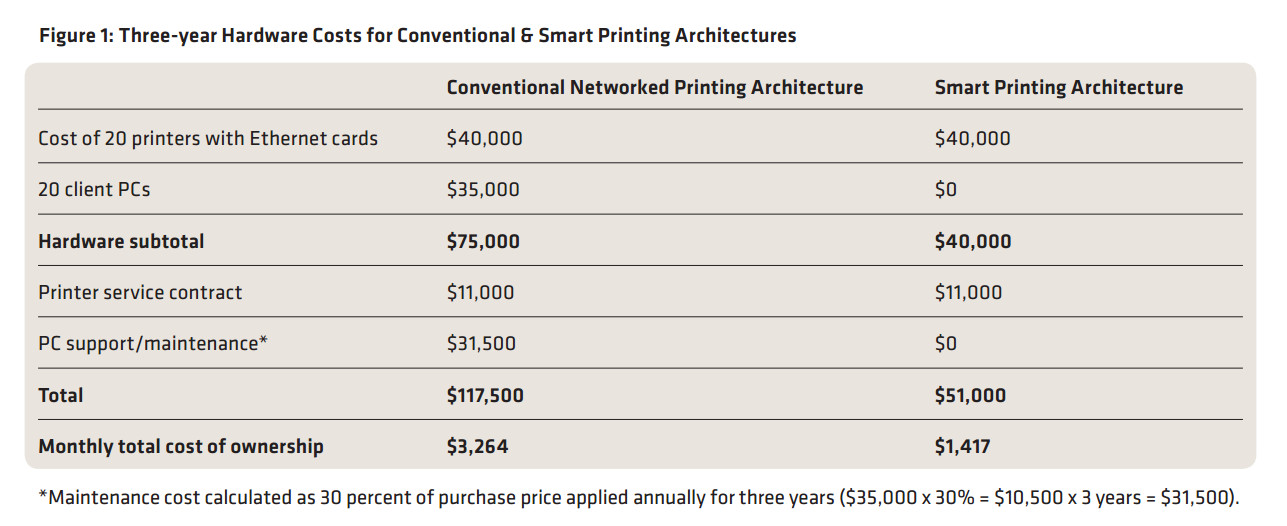

The table presents estimated costs to run 20 printers in a hypothetical production or distribution facility for three years. In this 20-printer environment, a conventional solution’s cost is more than double that of a smart printing architecture. Note that smart printers do not necessarily cost more than conventional ones; pricing policies vary by manufacturer and model.

As the chart shows, the hardware-related TCO for a smart printing implementation is less than half of that for conventional printers. The comparison does not include the cost of print servers, which are sometimes also used in conventional implementations. Organizations that have already purchased PCs to support legacy printers can redeploy them, or at least retire the computers and save on support.

The deployment expense advantages for smart printing systems often go beyond hardware cost avoidance. Smart printing applications tend to be less complex than computer-based printing operations, which frequently require developers to create custom interfaces between the printer and enterprise systems. Printer-resident applications often take less time to create, test and install, resulting in lower development costs.

Support Advantages to Smart Printing

Smart printers can also streamline IT processes in ways beyond the major benefit of not having to support PCs that control printers. Onboard intelligence and two-way communication enable support staff to manage printers proactively and reduce downtime. Having LCDs and control panels helps operators resolve issues without having to escalate support to the IT staff, which reduces the time the printer is out of service. Smart printers can be programmed to monitor their own performance, perform print quality checks and basic troubleshooting, and alert operators or system administrators to potential problems. Some models are compatible with IT asset management and data collection device management systems, which offer enhanced support capabilities.

Smart printers also may have special connectivity features to integrate with enterprise systems without requiring custom interfaces or other middleware. Most enterprise software applications do not support label printer command languages, which means thermal printers do not have the native ability to output print jobs from these applications. The issue is typically resolved by using labeling software and/or a printing server to convert data from enterprise systems into a format the thermal printer can understand. Some smart printers can connect directly to enterprise software applications, which allows organizations to avoid using printing servers and other intermediate steps. XML provides one way to connect smart printers and enterprise systems. Smart printers with an embedded XML parser can print from any application that support XML, including the SAP Auto-ID Infrastructure (AII) and Oracle WMSand Mobile Supply Chain Applications (MSCA). Organizationsthat run these and other XML-compatible applications value smart printers because they free the IT staff from additional software development and maintenance to support printing.

Conclusion

With smart printing, organizations can install printers wherever they are most advantageous for operations – not where PC placement or network access dictate. This flexibility to conduct logic-controlled printing anywhere helps create more efficient work processes that keep costly errors out of operations. The result is lower operating costs without a tradeoff in decreased worker productivity or higher implementation and support costs. In fact, smart printing systems typically cost less to implement than conventional, computer-dependent architectures, are easier to maintain, and provide more opportunities to integrate printers to leverage previous investments in enterprise software and IT management systems.