Barcode Vs. RFID: Things to Consider Before You Choose

Barcode and RFID labels are choices that enterprises must choose to improve efficiency. Which are the most cost- effective and reliable in the long run for your operation?

Here are a few things you should consider

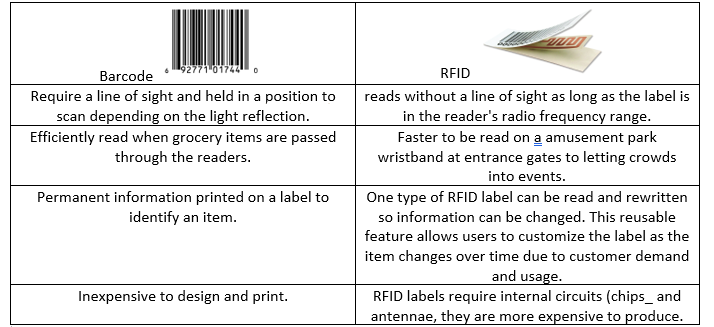

Barcodes Vs. RFID

RFID labels have electronically generated unique codes and barcodes use standard protocols. In an inventory collection setting, a barcode label can tally up items in the stock according to product type, manufacturer, and stock level. Employees will have to manually check for item specifics such as color, price, and purchase date of individual items. On the other hand, RFID labels are capable of loading up 2,000 proprietary byte of information and be able to tally up individual items in inventory too.

For example: A barcode label would be able to tell a grocer how many gallons Milk A and Milk B was in the cooler but an RFID label will be able to disclose where each gallon of milk came from the farm and distributor.

Ultimately, if printer properly both barcode and RFID tags can eliminate human error and contribute to enterprise efficiency compare to when items are accounted for by hand. Purchasing either barcode or RFID solutions depends on the depth of data required by an enterprise and how the system will be used in the field. Label consumers have to make a decision based on the needs and financial constraints.

If you need guidance on which solution to choose, feel free to contact one of our dedicated account managers and we will be happy to help.

Metalcraft RFID Assest Tags Printed on SATO CL4NX