The Value of RFID in Inventory Management & Supply Chain Visibility

Radio Frequency Identification (RFID) is revolutionizing inventory management and supply chain visibility. While barcodes have been the dominant tool for item identification for decades, RFID offers a powerful alternative with advantages like real-time tracking, non-line-of-sight reading, and faster automation. Although RFID implementation requires more planning and investment than barcoding, it can provide significant efficiency gains for businesses seeking to streamline operations and reduce errors.

Why RFID is Worth Considering

To determine if RFID is the right fit for your business, it’s important to evaluate your needs and operational challenges. Unlike barcodes, RFID does not require line-of-sight to read tags, which makes it ideal for tracking items moving through conveyor systems or stored in hard-to-see locations. The technology also supports varied read ranges, from a few inches to over 10 feet, depending on the tag and reader setup. RFID can be particularly effective when items are traveling at high speeds or are fixed at certain checkpoints.

However, environmental factors must be considered. Items containing metal or liquids can interfere with RFID signals, impacting system performance. Similarly, the choice of fixed or mobile readers depends on whether you need automated scanning at warehouse entry points or manual inventory checks on the move.

Types of RFID Technologies

RFID operates in three main frequency ranges. Low Frequency (LF) systems work well for close-contact applications like ID badges or access control, but their range is limited to a couple of inches. High Frequency (HF) systems can read tags up to 3 feet away, making them ideal for small item tracking and applications like healthcare equipment management.

For supply chain and inventory purposes, Ultra High Frequency (UHF) is the most widely adopted RFID solution. UHF systems offer extended read ranges of up to 10 feet, making them highly effective for item-level and container-level tracking. UHF’s affordability and flexibility have made it a popular choice for businesses looking to manage large volumes of inventory efficiently.

RFID tags are also classified as active or passive. Active RFID tags have their own battery power, enabling long-range and high-speed scanning, but they are costly and bulky. Passive tags, on the other hand, rely on the reader’s signal for power, making them thinner, more affordable, and ideal for product-level tracking in inventory systems.

How RFID Works

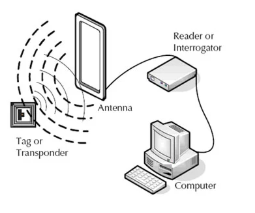

A typical RFID system includes four key components: tags, antennas, readers, and host software. When a passive RFID tag enters the signal field of an antenna, the tag receives power from the reader. It then “backscatters” its stored data, which is captured by the antenna and processed by the host software. Unlike barcodes, RFID tags can be read even if they are not in direct view or perfectly oriented, enabling faster and more efficient inventory tracking.

The host software uses the captured data for applications such as asset tracking, inventory control, or logistics management. For example, fixed RFID readers can monitor inventory as it passes through warehouse doors, while mobile readers allow employees to conduct manual counts while on the move. Desktop RFID readers offer a plug-and-play option for situations that require reading tags next to a PC, such as retail checkouts or quality control stations.

Challenges and Limitations

While RFID is highly effective, it is not without limitations. Environmental factors such as metals and liquids can interfere with signals, reducing accuracy. Dense collections of items may also pose challenges, as tags in the center may not receive enough signal power to activate. These factors require extensive testing and system design to achieve optimal results.

Additionally, RFID systems involve higher upfront costs compared to barcode solutions. However, businesses that plan carefully and implement RFID effectively often achieve significant long-term savings through reduced errors, improved accuracy, and labor efficiency.

Components of an RFID System

An RFID system begins with the selection of the right tags, which are designed with a combination of chipsets and antennas to store and transmit data. The choice of tags depends on the environment, product type, and read requirements. For high-volume applications, RFID printers simplify the process by encoding tags and printing barcodes as a backup, ensuring data accessibility even if the RFID tag is damaged.

The RFID readers themselves come in various forms. Fixed readers are ideal for automated scanning at checkpoints, such as warehouse docks or conveyor lines. Mobile readers, which resemble handheld computers, are versatile tools for conducting inventory counts and asset tracking across facilities. Desktop readers, though limited in range, offer quick and easy data capture for localized applications.

Finally, middleware software ties the system together. Unlike barcode scanners, RFID readers do not output basic text data directly. Instead, middleware processes the RFID data and integrates it with inventory management or enterprise software. Systems supporting Low Level Reader Protocol (LLRP) ensure compatibility with most RFID readers.

The Benefits of RFID in Supply Chain Management

The greatest value of RFID lies in its ability to enhance efficiency, accuracy, and automation. It enables businesses to track inventory in real time without requiring manual scanning. By reading multiple tags simultaneously, RFID reduces the time and labor involved in inventory checks. Its non-line-of-sight capability allows for greater flexibility, especially in environments where items are stacked, moving, or difficult to access.

Conclusion

RFID technology is transforming the way businesses manage inventory and supply chains by offering faster, more accurate, and automated tracking solutions. While the technology presents challenges, such as signal interference and higher initial costs, the benefits far outweigh these limitations when implemented correctly.

For businesses exploring RFID, it is best to start with a small-scale pilot project, test its feasibility, and gradually scale up. With careful planning and the right resources, RFID can provide unparalleled visibility and efficiency in your inventory management processes, giving you a significant edge in a competitive market.

How Connected Packaging Powers the Circular Supply Chain

Connected packaging is revolutionizing supply chains, boosting efficiency, and driving sustainability. John Dwyer, Vice President of Digital Innovation at Smurfit WestRock, highlighted the transformative potential of Born-Digital packaging during a guest session hosted by Levata. Barcodes, Inc. is a Levata company.

By combining cutting-edge technologies like traceability, automation, and circular economy principles, Smurfit WestRock is redefining the role of packaging in modern business. Below is an overview of Dwyer’s insights and the impact of Born-Digital packaging on sustainability and supply chain efficiency.

Transforming Supply Chains with Connected Packaging

Traditional supply chains often face inefficiencies, including waste from overstocking. The pandemic exposed these vulnerabilities, emphasizing the need for smarter, connected solutions.

Smurfit WestRock’s Born-Digital packaging integrates advanced technologies like RFID, Bluetooth Low Energy (BLE), NFC, and serialized QR codes into packaging, creating digital identities for products. These innovations enable real-time tracking, improve inventory visibility, reduce waste, and optimize delivery timelines.

For instance, Smurfit WestRock collaborated with a quick-service restaurant chain to track fresh beef throughout its supply chain. By incorporating RFID technology into refrigerated packaging, the company ensured precise, scalable solutions for transitioning from frozen to fresh beef—an essential step for maintaining quality and meeting demand.

Driving Recycling and Sustainability

Sustainability is at the core of Smurfit WestRock’s operations. The company operates 32 recovery facilities in North America, collecting two-thirds of Walmart’s packaging waste and transforming it into new materials. This closed-loop system supports retailers’ ESG goals while reducing waste.

A standout example is Smurfit WestRock’s leadership in the pizza box market, producing approximately 3 billion boxes annually, covering 55% of the U.S. market. Domino’s has introduced QR codes on its boxes to educate customers about local recycling guidelines. Research conducted by Smurfit WestRock confirms that pizza boxes are recyclable, even with food residue, further reducing environmental impact.

Key Trends Shaping Born-Digital Packaging

Several key trends are driving the adoption of connected packaging:

- Real-Time Data Demand: Businesses require instant access to data for better decision-making, particularly in retail and logistics. Connected packaging improves inventory accuracy and supply chain visibility.

- Enhanced Connectivity: Innovations like Wi-Fi 6E and 5G ensure seamless data transfer in harsh environments.

- Circular Economy Integration: Businesses are prioritizing recyclable materials and digital traceability to minimize environmental footprints and meet regulatory standards.

Smurfit WestRock is leading the charge with advanced solutions like light-sensitive sensors that detect unauthorized package openings, enhancing security and trust. By creating scalable, end-to-end systems in partnership with companies like Barcodes, Inc. and SLS, the company ensures seamless integration of sensors, readers, and gateways to address complex supply chain challenges.

Maximizing ROI with Smart Packaging

Connected packaging offers businesses significant returns on investment, often within 12 months. Automating processes like cycle counting allows organizations to redeploy labor to higher-value tasks, reducing costs and improving efficiency.

For instance, smart packaging helps retailers avoid costly penalties for incomplete or late shipments by providing electronic proof of delivery.

A Vision for a Sustainable Future

John Dwyer concluded his presentation by reaffirming Smurfit WestRock’s dedication to the circular economy. Approximately 30% of old corrugated containers in the U.S. are recycled into new packaging, showcasing the company’s commitment to sustainability. As regulations like FSMA and EPR evolve, Smurfit WestRock’s ability to track and recycle packaging will remain a vital tool for achieving compliance and advancing sustainability.

Discover the Future of Packaging

By combining innovation, sustainability, and strategic partnerships, Smurfit WestRock is revolutionizing packaging and creating a smarter, more connected supply chain. Learn how your business can leverage connected technologies, recycling innovations, and sustainable practices to transform your operations and meet evolving market demands.

Contact us today to explore the power of Born-Digital packaging in driving a sustainable, circular economy.

From Challenges to Triumph: Yamaha G3 Boats’ RFID Journey

When Yamaha G3 Boats faced challenges with visibility, efficiency, and tracking in their production process, they turned to Barcodes, Inc to implement an RFID solution. This strategic move aimed to increase production capacity and streamline operations, ultimately paving the way for significant growth and improved productivity. Their success was recognized with the ‘Best Manufacturing Implementation of RFID’ award at the 2024 RFID Journal Live, demonstrating the impact of advanced technology in overcoming operational bottlenecks.

About Yamaha

Yamaha G3 Boats is renowned for producing high-quality aluminum fishing boats and recreational pontoon boats. With a strong commitment to craftsmanship and innovation, they’ve earned a reputation for delivering durable and reliable vessels. Their product range caters to both avid anglers and recreational boaters, offering top-notch performance and comfort on the water. Yamaha G3 Boats is also known for their continuous improvement initiatives, consistently integrating advanced technologies to enhance both manufacturing processes and product offerings.

Barcodes, Inc Advantage

To tackle the challenges of visibility, efficiency, and tracking in their manufacturing process, Yamaha turned to Barcodes, Inc’s cutting-edge RFID systems, which delivered an ideal solution. By deploying RFID technology, Yamaha was able to:

- Enhance Visibility: Barcodes, Inc’s RFID technology provides real-time visibility into the production line. RFID tags attached to each boat and key components allow Yamaha to track their location and status at every stage of production. This real-time data enables the company to quickly identify and resolve issues, ensuring smoother production processes.

- Improve Efficiency: With comprehensive tracking capabilities, RFID technology optimizes workflow on the shop floor. Identifying bottlenecks and streamlining operations allows Yamaha to meet production schedules more accurately and efficiently. Additionally, automated data entry and ERP system integration further boost operational efficiency.

- Accurate Tracking: RFID tags enable precise tracking of each boat throughout the manufacturing process. This accuracy minimizes errors and improves resource allocation. Real-time tracking of every component and work order ensures production stays on schedule, leading to improved throughput.

Looking Ahead

Yamaha G3 Boats continues to expand its RFID capabilities with future phases planned. By partnering with Barcodes, Inc, Yamaha remains poised to meet market demands and maintain their competitive edge.

The success of Yamaha G3’s RFID implementation is a milestone for Barcodes, Inc, and we look forward to continuing this partnership to achieve even greater accomplishments. Congratulations to everyone involved in this project!

From Farm to Fork: Ensuring Food Safety with Effective Labeling

Food safety is a top priority for everyone involved in the food supply chain, from farmers and manufacturers to distributors, retailers, and ultimately, consumers. Contaminated food can cause serious illness, and preventing these outbreaks requires a multi-pronged approach. One critical element in this strategy is effective food safety labeling. The best food label printers are designed to meet the specific requirements of the food industry, offering advanced features that enhance food safety practices. Read further to learn the importance technology plays in ensuring accurate and efficient labeling practices.

Why Food Safety Labeling Matters

Food safety labeling plays a crucial role in safeguarding consumers from potential hazards. It allows for accurate tracking of food products throughout the supply chain, facilitating swift and targeted action in case of recalls or contamination concerns. Clear and consistent labeling also empowers consumers to make informed choices about the food they eat.

Here are some specific ways food safety labeling contributes to a safer food system:

- Traceability: Labels with essential information like batch numbers, expiration dates, and processing facilities enable tracing in the event of recalls.

- Allergen Awareness: Clear and accurate allergen labeling on food packaging allows consumers with allergies to make safe choices.

- Ingredient Transparency: Detailed ingredient lists on labels help customers with specific dietary needs or preferences make informed choices.

- Best-Before Dates: Best-before dates advise consumers when food maintains its optimal quality and safety.

- Instructions and Warnings: Labels can include instructions for proper handling, storage, and preparation of food.

Technology’s Role in Food Safety Labeling Accuracy and Efficiency

Label printer technology plays a vital role in ensuring the accuracy and efficiency of food safety. As North America’s leading provider of barcode and product labeling, mobile computing, and RFID solutions, Barcodes Inc. partners with the most trusted brands in the food service and grocery industry that offer unique food labeling features.

- Digital Printing Solutions: Advanced digital printing technologies facilitate on-demand printing of labels, allowing for real-time updates and increased flexibility. This reduces waste and ensures the most recent information is included on labels.

- Variable Data Printing: This technology allows for printing unique information like lot codes and expiration dates on each individual label, enhancing traceability and facilitating targeted recalls if needed.

- Label Management Software: Centralized software solutions streamline the creation, approval, and printing of food safety labels, fostering consistency and reducing errors.

- RFID (Radio Frequency Identification) Technology: RFID tags embedded in food packaging offer enhanced traceability as they can track food products throughout the supply chain in real-time.

SATO: Empowering Businesses with Food Safety Labeling Solutions

Not all label printers are created equal. SATO food safety label printers are a top-shelf choice in the food and grocery industry for their durability, resistance to moisture and temperature fluctuations, and crisp, clear label printing. Here are a few reasons SATO printers remain a top choice for food manufacturers and retailers:

Improved Efficiency: High-speed printing and easy integration with existing systems streamline labeling processes, reducing bottlenecks and improving overall productivity.

Enhanced Traceability: Accurate and legible labels facilitate effective tracking of food products throughout the supply chain, ensuring compliance with regulatory requirements.

Durability and Reliability: SATO printers are built to withstand tough conditions, ensuring uninterrupted operation in food production environments.

Versatility: The printers can accommodate a wide range of label materials and printing applications, meeting the diverse needs of the food industry.

SATO is the innovator behind DateRight™ Rotation Labeling, a solution to streamline food storage and rotation in food service outlets. The label incorporates seven color indicators that represent the days of the week, allowing for easy visual identification of expiring products and promoting FIFO (First-In, First-Out) inventory management.

Let’s explore two popular food label printer models by SATO, the CL4NX Plus and CT4-LX printers.

SATO CL4NX Plus RFID Label Printer:

High-Speed Printing: The CL4NX Plus delivers rapid printing speeds up to 10 ips, reducing labeling bottlenecks and improving overall production efficiency.

UHF RFID Module: Print text and barcodes on UHF tags/labels and encode data in their embedded chips at the same time. The CL4NX Plus is even capable of checking RFID chips prior to encoding to verify their readiness to use and to prevent failures.

Flexible Media Handling: The printer can accommodate a wide range of label materials, including those with special coatings or adhesives, ensuring compatibility with various food packaging applications.

Advanced Connectivity Options: The CL4NX Plus offers seamless integration with existing systems, enabling efficient data transfer and label printing.

Learn more about the SATO CL4NX Plus.

SATO CT4-LX Label Printer:

- Compact and Portable: The CT4-LX is a 4-inch compact and portable printer, making it ideal for mobile labeling applications in food production facilities.

- Patented Label Waste Prevention: SATO’s patented label waste prevention feature helps minimize label waste, contributing to cost savings and environmental sustainability.

- High-Resolution Printing: The printer delivers clear and legible labels, ensuring accurate product information and traceability.

- Wireless Connectivity: The CT4-LX offers wireless connectivity options, enabling mobile workers to print labels from remote locations.

Learn more about the SATO CT4-LX.

By incorporating high-quality food label printers like the SATO CL4NX Plus RFID and CT4-LX printers into their operations, businesses can enhance food safety labeling practices, improve efficiency, and ensure compliance with regulatory standards. Barcodes, Inc. is a leader in supply chain solutions, offering high-quality thermal printers and compatible labels specifically designed for unique industries. For help finding the right labeling solutions for your business, contact Barcodes Inc. today.

The How and Why of RAIN RFID Cryptographic Authentication

The problem of counterfeit products is global, and it’s growing. Knockoff handbags, athletic shoes, wristwatches, and pharmaceuticals cost businesses and consumers billions of dollars every year globally.

Now, there’s a new way brands can fight fakes: RAIN RFID cryptographic authentication.

The Impinj Authenticityâ„¢ solution engine brings enterprise-scale product authentication to new and existing RAIN RFID deployments.

What is Product Authentication?

At its heart, authenticating something is largely straightforward: You want to conclusively establish the item as genuine and determine its owner or origin. Doing that can get complex.

Product authentication solutions built on the Impinj platform employ secure cryptography, using a challenge-response protocol to determine with a high degree of certainty whether an item is genuine.

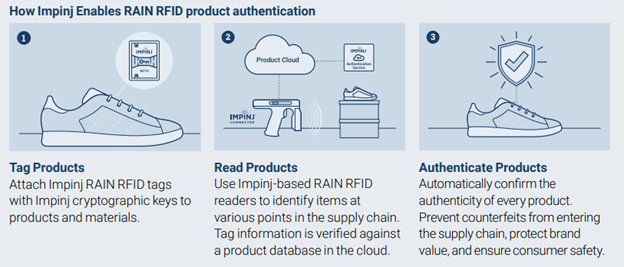

RAIN RFID from Impinj

An item tagged with RAIN RFID has certain information associated with it—data such as the manufacturer name, model number, serial number, date of manufacture, purchase date, customer name, and more. That item-specific data can be stored in a product cloud.

When that item is read at any point in the supply chain by a RAIN RFID reader, an Impinj-based authentication solution cross-checks and confirms the information stored in the product cloud and verifies the tag’s authenticity using the Impinj Authentication Service.

Impinj Authenticity uses cryptographic authentication, a feature of the new RFID tag chips, to swiftly and automatically verify tagged products as genuine.

Implement RAIN RFID with a Trusted Partner

For an in-depth explanation of how Impinj Authenticity works, contact Barcodes, Inc. to learn more about RAIN RFID.

RFID Webinar: Improve Returnable Container Tracking with RFID

Webinar

Improve Returnable Container Tracking with RFID

Thursday April 20th 1:00-1:45pm Central

PRESENTED BY:

Christopher Vassilos – Senior Solutions Architect, Barcodes Group

Michael Daily – Senior Solutions Engineer, Impinj

RFID-Based Container Tracking

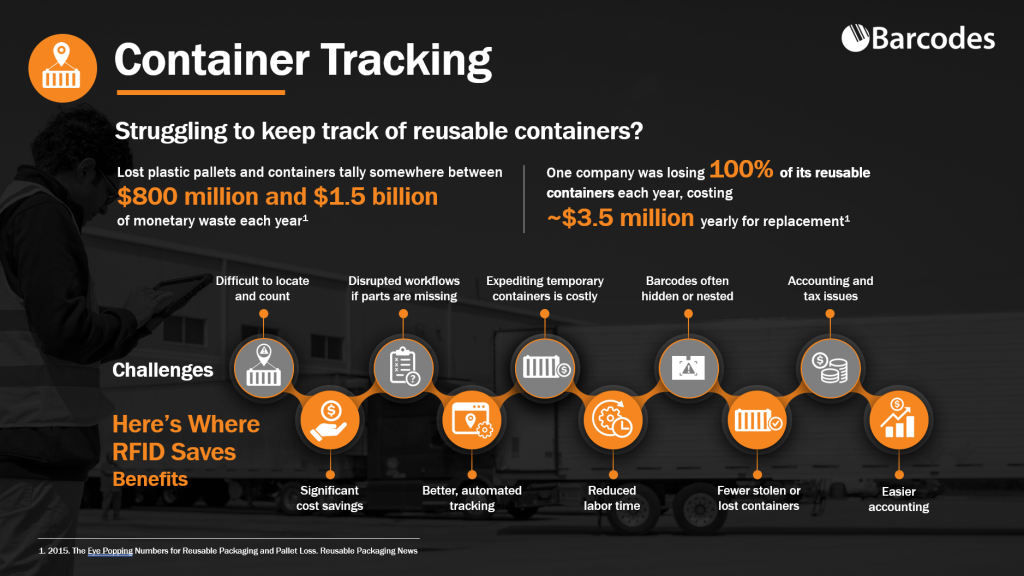

Upon delivery, it’s common for reusable containers to not be returned to the sender, with annual shrinkage rates often exceeding 10%. Keeping track of your Returnable Transport Items (RTIs) can be challenging, especially when logging their location depends on manual processes like scanning.

In this webinar, discover the benefits of RFID-based container tracking:

- Reduce the number of misplaced pallets, kegs, and boxes. Less new delivery assets need to be purchased, and shipments are not interrupted due to lack of totes.

- Track each asset as it leaves and returns to the warehouse, allowing you to determine its exact location immediately and whether they have yet to return.

- Calculate the flow of returnable assets to fully understand your shipping capacity for the present and future.

- Improve utilization of workers since it takes way less time to scan RFID tags than barcodes, due to its fully automatable reading without line-of-sight requirements.

Watch the Full RFID Webinar Recording

Improve Returnable Container Tracking with RFID

Returnable Transfer Items (RTIs), or returnable containers are critical assets for almost all manufacturing and logistics organizations. RTIs transport stock and commodities from one site to another. However, keeping track of your RTIs is a different story. Well-known manufacturers and logistics expert still often rely on manual methods, such as traditional scanning, spreadsheet, or pen and paper.

This leads to a major issue: inventory shrinkage.

Mismanagement of returnable containers owing to theft, unrecorded damage, or simply the inability of consumers to return empty pallets, kegs, and boxes costs a fortune.

How are Your Returnable Transfer Items Being Tracked Currently?

Barcode labels used to tag the cargo of a container during shipment are often non-permanent. Traditional barcode scanners and labels identify the contents of the container, but seldom provide reverse logistics tracking for the containers themselves.

Using permanent barcode labels as the foundation for a container monitoring system is not feasible. I know that might be strange to hear from a company called Barcodes, Inc. But scanning labels at various stages of the supply chain sometimes necessitates extra human effort, which is even more difficult when empty containers pile up.

One solution is to establish a tracking system utilizing modern asset tracking technology.

Reducing Yearly Inventory Shrinkage with RFID

“15% of all pallets in circulation vanish” or “20% of all packaging/equipment is lost owing to consumers retaining them for their own use or third parties removing them for their own use.”

SLS RFID 2016 Study

Inventory shrinkage is a major issue in the management of returnable transfer items (RTIs), which include all types of shipping containers, packaging, pallets, kegs, and boxes.

Shrinkage due to theft, unreported damage, or just consumers failing to return empty containers is a serious concern in this field.

Estimated annual shrinkage rates are anywhere from 3 to 9%. If you’re constantly replacing lost or stolen RTIs, the impact on profitability is a huge problem.

For organizations to decrease RTI shrinkage, RFID is appealing due to completely automated scanning without line-of-sight, as well as mass tag reading. The key advantage of RFID-based container monitoring systems is an improvement in container return rates. New containers are purchased in smaller batches and less frequently.

What Data Can Be Tracked with RFID Tags?

Integrating the RFiD Discovery system with your ERP system enables company-wide visibility of your RTIs, ensuring that essential assets are accessible at the relevant locations to fulfill any transportation request.

Exactly what the RFID ultimately tracks depends on your unique tracking requirements. Here are some examples of the depth of data you can store in a small RFID tag:

- Container Name

- Size

- Location

- Weight

- Item Quantity

- Container Properties

User memory on tags stores data. The serial number field can be pre-programmed or user-assigned.

The air-interface protocol standards for passive HF and UHF tags, such as UHF EPC Gen 2, define basic functions like read-write and which memory banks or blocks can be written to. Reader manufacturers include these low-level commands with higher-level subroutines in their software development kits for application developers.

How to Use RFID to Tag RTIs

RFID labels are long-lasting and more durable than traditional labels. RFID tags attach exceptionally well to returnable cargo and resist machine washing operations as well as harsh elements for much longer.

Any RTI equipped with an RFID tag can be detected by a small number of strategically located readers. The location data is delivered back to the central RFID Discovery database, where it may be evaluated.

This database allows you to discover how many RTIs have been sent to a specific supplier or customer, so you know which trade partner to approach when requesting a return.

When shipping containers are in range of an RFID reader, the information on the tags can be automatically acquired using a wide variety of methods:

- Fixed reader installed at a warehouse entrance or loading dock

- A mobile reader installed on a forklift

- Handheld reader brought inside a business partner’s facility for rapid inventory

What are the Main Advantages of Using RFID for Returnable Asset Tracking?

There are several advantages of using RFID to track returnable assets.

1. Recoup Billions of Dollars in RTI-Related Losses

Reusable assets are returned to the sender after delivery, usually full of new goods and not empty. Entire industries are dedicated to capitalizing on reverse logistics and maximizing the value of containers.

So why do we pay far less attention to reusable assets compared to sold commodities and container space? In order to get a bird’s eye view of costly shrinkage areas, your immediate shipping capacity, and overall supply chain health, it’s critical to assess the flow of returnable assets as well.

If RTIs arrive in the incorrect place or are lost, the transfer of products becomes difficult or impossible, thereby causing delivery delays. And massive container replacement costs.

These misplaced assets represent billions of dollars in losses, since new delivery assets must be acquired. We will say again: RFID saves billions of dollars.

2. Track Every Asset Location With a Detailed Evidence Trail

While we like to imagine most people are honest and good by nature, the reality is that customers and suppliers are not going to eager to assist when the subject of locating your missing valuables is brought up. Tough luck.

Instead of playing the blame game, utilizing an RFID system to track each asset as it leaves and returns to the warehouse allows you to instantly establish its specific location, and whether it has yet to return.

This goes for both goods sold as well as the RTIs carrying them. Put another way, your returnables are much more likely to return.

3. Increase Visibility of Container Locations, Available Stock, and Overall Condition

Though shipping should be a precise science, we know that’s not always the case.

Businesses depend on RTIs everyday, but lack visibility over the availability, location, and quality of their RTIs.

When organizations incorporate careful pallet monitoring, tote box tracking, and stillage tracking, it’s much easier to manage a large pool of RTIs without bleeding money. Additionally, there is no longer a need to keep just-in-case containers on the sidelines, because of increased visibility into the “who, what, where, and how many?” questions.

4. Improve Labor Utilization at Every Level of the Supply Chain

Scanning RFID tags takes substantially less time than scanning barcodes. Similarly, RFID is a more appealing identifying solution for reusable assets since users do not need to manufacture new barcodes or print new labels.

Logistics and operational leaders can simply re-encode the same RFID tags again and again without increasing headcount or allocating redundant processes to busy workers.

Lastly, RTLS on RFID can significantly reduce the amount of time workers spend searching for specific inventory. In a field such as healthcare, nurses estimate they spend at least an hour per shift finding equipment. That really adds up when looking at overall labor utilization.

Evaluating and Deploying an Effective RTI Tracking System

Tracking RTIs with RFID helps prevent your assets getting lost or stolen, reduces disputes between trading partners, enables rapid inventory cycle counting, and quickly identifies shortages. Your organization could be saving billions of dollars.

Barcodes, Inc. is your trusted RFID partner and integrator. Contact us when you are ready to elevate your RTI management and discover the magic of RFID tracking. It’s easier to deploy with a partner you can trust.

How to Select, Print, and Encode RFID Tags (Webinar)

About This Webinar:

How to Select, Print, and Encode RFID Tags

Wednesday, August 3rd, 2:00 PM – 2:30 PM ET

Presented By:

Chris Brown – RFID Subject Matter Expert at TSC Printronix Auto ID

Carlo Emanuele – Vice President and General Manager, Consumables at Barcodes Group

About the RFID Tag Webinar

IDTechEx forecast that 41.2 billion RAIN RFID tags will be sold in 2024, up from 15 billion just three years ago.

To enable you to track your assets with unprecedented accuracy, using the right tag will determine the success of an RFID implementation from the very beginning.

But how do you determine the encoding scheme to use at your organization, and the most appropriate tag or label to support this?

During this webinar, the following questions are answered:

- Why do you need to be concerned about encoding “good data†to RFID tags?

- How do you select an RFID tag that finds the optimal balance between size and read range?

- What role can a partner play in assisting with pre-printed/pre-encoded labels or providing solutions for your on-demand printing?

Watch the RFID Label Webinar

For an assessment of how RFID can improve your inventory accuracy and shipment verification process, please reach out to us at [email protected] or visit www.barcodesinc.com/solutions/learn-more-about-rfid/.

How RFID Cycle Counting Can Increase Speed at Lower Costs (Webinar)

About This Webinar:

RFID Cycle Counting: Increase Inventory Collection Speed at Lower Costs

Thursday, June 30th, 2:00 PM – 2:30 PM ET

Presented By:

Matt Smith – SLS

Christopher Vassilos – Barcodes

Why RFID for Cycle Counting is Transformative

Most businesses today conduct inventory counts as part of their operations. Traditional means of collecting this data include tallying products on a count sheet or scanning barcodes off product labeling, both of which are time consuming and prone to error.

Using RFID technology for cycle counting reduces labor cost and automates the workflow. The result is greater accuracy, improved asset utilization, as well as reducing lost or out of inventory situations.

During this webinar, you will be shown the following:

- A demonstration of cycle counting using RFID technology in action

- An overview of the components of the SLS Mobile Solution

- Various scenarios of deployment, including the use of robotics

Watch the RFID Cycle Counting Webinar Recording

We hope to see you there! For an assessment of your company’s ROI potential with RFID, please reach out to us at [email protected] or visit Barcodes and SLS RFID Solutions.

The Walmart Mandate: Tipping Point for RFID Adoption? (Webinar)

Webinar:

The Walmart Mandate: Tipping Point for RFID Adoption?

Thursday, May 12th, 2:00 P.M. – 2:30 P.M. ET

Presented By:

Todd Muscato – Barcodes Group

Ashley Burkle – Impinj

Ensure Your RFID Labels and Tags are Compliant Before September Deadline

After success using RFID for apparel, Walmart is expanding its RFID mandate to scores of additional products. Could it be a tipping point for RFID adoption in U.S. retail?

With heightened omnichannel demands and continued supply chain disruptions, retailers with inventory accuracy and visibility are thriving. How do you thrive instead of just survive with RFID in retail?

In this webinar, Barcodes and Impinj discuss the following:

- How RFID is helping big brand retailers adapt and thrive

- What retailers and their suppliers need to get started on their RFID journey

- How Barcodes can help with RFID solutions, including devices, software, tags, and support

Watch the Retail RFID Webinar Recording

Learn more about Barcodes’ Walmart RFID solutions, and contact us if you would like to have an exploratory discussion.