How RFID Increases Shipment Accuracy (Webinar)

Webinar:

How RFID Increases Shipment Accuracy

Thursday, March 24, 2022

Presented By:

Jeff Hudson – Barcodes Group

Matt Seltz – Zebra Technologies

Reduce Shipping Chargebacks with Integrated RFID Portal Solutions from Zebra and Barcodes

When your inventory is hard to identify or locate in the warehouse, it leads to incomplete, inaccurate, or delayed shipments. The annual cost of chargebacks due to mistakes in shipping is estimated to be $36B.

Reading RFID tags as they pass through portals or chokepoints is quickly becoming the most efficient and effective means of automating inventory and asset tracking.

Easy to implement and support, Zebra’s new Integrated RFID Portals easily validate shipments as they are loaded on or unloaded from trucks.

During this webinar, we discuss the following ways in which RFID increases shipment accuracy:

- Why RFID drastically reduces the need for human intervention and manual scanning

- What steps companies take to reach a 25% efficiency increase with RFID

- How Zebra’s new Integrated RFID Portals monitor inventory, control costs, and optimize workflows

Watch the Webinar Recording

RFID is a key technology platform that we would love to discuss in more depth with you. In a landscape with lingering supply chain delays and rising labor costs, RFID is one of the most cost effective, scalable, and reliable solutions available today. Learn more about Barcodes’ RFID solutions, and contact us if you would like to have an exploratory discussion.

5 Ways Traceability Can Improve Your Manufacturing Plant

Traceability and visibility are crucial measures for your manufacturing operation and production line. Proper traceability and visibility increase efficiency in the production line by catching defects before they leave the plant, thus reducing recall costs and effects. Without complete visibility, traceability systems will fail to report inaccuracies.

In fact, 69% of companies do not have total visibility over their supply chains, which leads many scrambling to prove everything is up to code during audits and inspections. When defects are identified in a product, organizations need to sort through mounds of data to track and trace raw materials. Otherwise, they may be facing a mass recall. These errors can cost your business millions of dollars, but the good news is that they are avoidable.

Effective tracking and locationing technologies empower manufacturing facilities to deliver fast, accurate, and quality service that secures efficiency for the whole supply chain. See how in our video:

Ensure Proper Tracing and Accurate Visibility with Barcodes, Inc.

Proper tracing and accurate visibility are key components to the well-being of manufacturing plants. Barcodes, Inc. ensures that your manufacturing plant is up to date with integrated solutions. Here are some ways proper tracing and visibility can impact your business.

- Streamline cause analysis – Having access to the data on your products enables manufacturers to dig deep and find the root cause of problems. Identify and solve problems faster to minimize impact.

- Consistent improvement – Once you are able to see how parts and products move through lines, it’s easier to see where improvement is needed. Knowing where and when bottlenecks and delays occur makes real-time optimization possible.

- Enhance your value stream – Since traceability and visibility monitors how your products move through your manufacturing process, it also helps with value stream mapping. Equipped with detailed product genealogy records, manufacturers gain supply chain visibility, which provides your operation the ability to see the bigger picture.

- Quality and engagement – Part traceability along the entire production line can also help find key points where quality check-ups should be added. It also increases accountability and engagement on the shop floor.

- Simple real-time tracking – Easy-to-use technologies such as Zebra’s locationing hardware simplify on-the-fly tracking of your high demand inventory, by digitally connecting data to your centralized management system. This means workers spend less time looking through files and reports for faster and more accurate audits.

Download our brochure to see more ways effective tracking enhances the production floor.

Contact us today to learn more about RFID technology designed to maximize traceability and visibility in your manufacturing plant.

How to Add an Extra Layer of Mobility to Your RFID Tracking System

Given today’s changing customer demands, new safety regulations, and the e-commerce boost, managing inventory continues to be a struggle for most warehouses and distribution centers. As a result, RFID has remained popular across industries since it accelerates throughput while increasing accuracy rates in both the receiving and loading docks. To take RFID efficiency a step farther, we recommend integrating it into your mobile printers with the ZQ630 and ZQ630 RFID:

Why combine mobility and visibility?

Inventory management has been cited as one the top struggles warehouses face today, which means solutions simplifying inventory management can help sharpen your competitive edge. A few issues that further complicate efficient management are:

- Sudden demand increases

- Lagging stock updated that leads to stockouts

- Increasing labor turnover rates that lead to high adoption rates for new technologies

- Lack of real-time visibility

By empowering your workforce with mobile RFID devices, you are able to streamline crucial tasks such as data capture, data sharing, and even label printing, ultimately delivering real-time updates across every avenue your workforce uses. For example, RFID mobile printing allows you to:

- Print updated RFID tags anywhere in your workflow in the event of sudden demand spikes

- Decrease processing time by eliminating unnecessary travel paths

- Deploy an end-to-end tracking system with easy-to-use devices for faster onboarding

- Label incoming inventory immediately with RFID tags to start tracking stock in real-time

- Lower employee density in printing stations

- Increase mobility with lightweight enterprise-grade devices

Working alongside your team, Barcodes, Inc. assists with design, deployment and support services to maximize printer uptime, so your workforce can confidently manage inventory with tools that move with them. Contact us today for a free consultation to see where can implement RFID mobility in your operations.

Why Maximize Visibility in your Work-In-Progress Inventory?

When creating lean operations, manufacturing plants often struggle with managing, incoming materials for future orders, known as work-in-progress (WIP) inventory. If left unchecked, unidentified WIP inventory can increase operational costs by at least 20%[1] while ultimately leading to:

- Increased labor and downtime costs

- Dwindling storage space

- Difficulty tracking assembled orders

- Missed opportunities as decision must be based on available space instead of demand

Better identification equals better visibility

To ascertain material identification for WIP inventory, Barcodes, Inc. recommends modernizing your labeling system. Industrial printers such as Zebra’s ZT610 ensure barcode legibility for both barcode labels and RFID tags, so your team can accurately identify materials as they move throughout the production floor.

By accelerating printing speeds, industrial printers empower teams to quickly tag incoming materials, securing proper storage in the correct location before materials leave the receiving dock. Furthermore, high-resolution barcodes facilitate more successful first-time scans, simplifying your inventory management process as materials move down the supply chain.

However, while industrial printers offer a good place to start enhancing operations, there are many more ways to continue eliminating inefficiency. As a Zebra Premier Business Partner, Barcodes, Inc. works closely alongside your team to design, deploy and support enterprise-grade hardware into your operations. Contact us today to see how you can pair printers like the ZT610 to scanners, mobile computers, and consumables to expand inventory visibility. Â

[1] Reduce Work-in-Process (WIP) Inventory and Costs. General Electric.

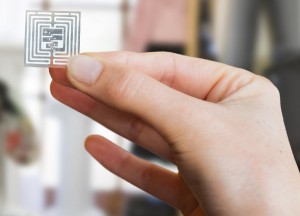

Where to Place an RFID Inlay

Printing and encoding RFID “smart labels†with an RFID-enabled printer has traditionally been difficult; a classic case of “the Devil is in the details.â€â€¯ One difficulty users have wrestled with has been “inlay placement.â€â€¯ Inlay placement refers to the location of the RFID inlay under the label’s face stock.  Although inlays are generally oriented horizontally under the face stock, the inlays can be located towards the bottom of the label, towards the top, or anywhere in between.  In the picture to the right, for example, the inlay is relatively close to the bottom of the label, the “leading edge†as it is often called, because this edge comes out of the printer first.

Almost every printer brand – and even model – has traditionally had detailed, complex specifications regarding inlay placement, with different specifications for each and every inlay on the market.  The location of the inlay has to be a particular distance from the leading edge of the label in order to maximize the printer’s throughput (speed).  Just a millimeter or two either way, and the performance of the printer can suffer dramatically.  What a mess.  Given that printing and encoding RFID labels is already slower than printing traditional barcode labels, any further loss in performance has often been catastrophic for the end-user.  Waiting for your RFID labels to print and encode can hold up an entire production line.  This all meant that for your printer brand and model, you needed to make sure to order labels with an optimal inlay placement.

Precise inlay placement also causes some additional problems:

- It makes selecting labels more difficult. Users need to order their labels very carefully to ensure correct inlay placement.  Does your purchasing department understand inlay placement?

- It can cause delays in sourcing labels.  Often, a convertor (label manufacturer) will have exactly the label size you need – but with incorrect inlay placement for your printer.  To get labels with optimal inlay placement, the convertor needs to configure their entire production line and run a new batch of labels for you.  This can take several days to several weeks.

- Finally, requiring a specific inlay placement can mean that users may pay more for their labels.  A quick Google search of classic paper thermal transfer 4×6 RFID shipping labels will show some surprising results.  The very same labels from the very same vendor can have dramatically different prices depending solely on inlay placement.  It all boils down to supply and demand, but if you are on the wrong side of the equation, you may have to pay significantly more for your labels.

With Printronix Auto ID’s current line-up of RFID printers, these headaches associated with inlay placement are now a thing of the past.  Printronix RFID printers have a unique firmware (the software brains in the printer), which does what they call “Encode During Print.â€â€¯ In clearer language, this means that the printer will first print some of the label, then switch over to encoding, then switch back to printing and finish up the label.  The printer will automatically either print or encode at any given moment depending on where the label is relative to the printer’s printhead and RFID encoder.  The traditional approaches for RFID printers were to either first print the entire label, then encode the RFID portion (“Print then Encodeâ€) – or to first encode the RFID, then print the label (“Encode then Printâ€).  But with these traditional approaches, if the inlay is not optimally placed, then the printer needs to back- or forward-feed the label to align it for an operation (printing or encoding) at any given moment.  With Printronix’s Encode During Print functionality, back- and forward-feed are eliminated (other than to overstrike bad labels, which is another blog topic for another day), regardless of inlay placement.

So far, we have been talking about labels like 4×6 shipping labels that allow different inlay placements.  But what about all of the RFID labels, “tags,†on the market that have predetermined inlay placement?  For example, on-metal tags, plant stakes, small pharmaceutical labels for cold-chain applications, “RTI†tags (Returnable Transport Items), etc., etc.  There are many such tags on the market, and more are being developed and released all the time.  These tags generally have a fixed inlay placement based on their physical design and on simple commercial considerations – they are meant to be “Off-the-Shelf†(OTS) products.  This is another area Printronix’s Encode During Print functionality shines even more.  Because the Printronix printers do not care where the inlay is located, you can use any of these tags and still achieve maximum throughput.

And these unusual tags often pose physical feed challenges for RFID printers. For example, on-metal and RTI tags are often thicker than normal smart labels, and they can have abrupt edges between labels, large gaps, etc. Both Printronix’s T6000e and T4000 series printers were designed from the ground up to work with these more difficult constructions.  The printers are spec’ed for labels up to 1.2mm thick and are available in 4†and 6†print-widths, allowing you to print and encode a wide variety of tags from a single printer – all without sacrificing performance.

Finding the right RFID solution is always a challenge and having the right resources and help are critical. If RFID sounds like a suitable solution for your business or you have additional questions, feel free to contact us at Barcodes, Inc. We’re always happy to help you find the right solution for your needs.

Advantages of RFID for Retail

Apply the power of RFID (Radio frequency identification) in your retail environment! RFID technology goes beyond barcode scanning. It automates data collection without the risk of human error. With an RFID handheld scanner, you can read tags simultaneously and without direct line of sight increasing efficiency and productivity in a store.

All RFID tags within range can be tracked and located immediately to ensure the correct location from supply chain to on the floor. Retailers can have access to product information, item location, availability, item level tracking, stock maintenance to ensure greater efficiency and sufficient supply level to meet consumer demand.

Introducing the Alien ALR-S350 Sled RFID handheld reader, it is an robust, simple, cost effective RFID reader that is designed for all day use. Supports Apple iOS or Google Android via smart device you will be able to gain the flexibility and accuracy you need on the retail floor. Unlike competitive sled units, the Alien ALR-S350 RFID reader comes with everything required to begin to use, the kit comes with charging kit, cradle dock, and micro USB cable. All the user need is the smart phone or tablet device to bring visible information on the go.

Features:

- Capable of scanning 1D and 2D barcodes (QR codes)

- Reads up to 200 tags per second

- 3 LEDs and buzzer for user feedback

- Supports Apple iOS and Google Android Devices

- Robust Design IP54 feat Quadlock for phone mounting

- Bluetooth 4.2 connectivity for simple smart device pairing

- Up to 24 hours of intensive use- long battery life

Manually scanning barcodes or counting products is time extensive, employees must move aisle to aisle, locating items individually. With RFID scanners, workers can read tags as far as 20 feet away and at hundreds of tags per second. Contact Barcodes to learn more about how the Alien ALR-S350 Sled RFID reader can help you to increase accuracy and gain more visibility in your data collection.

Impinj’s Luggage Tracking Solution with Monza Tag Chips

With major airlines using Impinj Monza tag chips to help track luggage, it’s exciting to see this technology grow. The International Air Transport Association (IATA) voted to approve a mandate requiring member airlines to implement RFID baggage tracking. The implementation is set with the goal of rolling out the technology globally by 2020. According to IATA, member airlines represent 83% of the global air traffic, with the tracking solution in place consumers can track the movement of their luggage from their phone.

With major airlines using Impinj Monza tag chips to help track luggage, it’s exciting to see this technology grow. The International Air Transport Association (IATA) voted to approve a mandate requiring member airlines to implement RFID baggage tracking. The implementation is set with the goal of rolling out the technology globally by 2020. According to IATA, member airlines represent 83% of the global air traffic, with the tracking solution in place consumers can track the movement of their luggage from their phone.

Airlines and airports are no stranger to RAIN RFID, London Heathrow and Las Vegas’s McCarran Airport already use the tracking solution from finding a trolley to sorting and tracking luggage. These types of baggage tracking solutions, among others, have helped the industry drop their lost luggage rate by 70% over the last decade.

Monza tag chips features:

Monza tag chips features:

- High performance to achieve excellent read and write sensitivity

- Interference Rejection to yield outstanding reads

- Omnidirectional Performance in every direction

This is great example of how technology impacts our everyday lives, whether its down on the ground or 40,000 feet above!

Talk to our dedicated account managers to see how we can help you with tracking solutions in your business today!

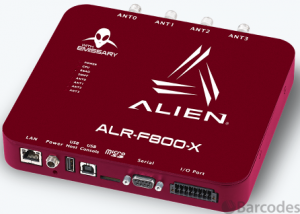

Simplify RFID Deployments with Alien’s RFID Readers

Alien Readers are built for challenging environments that commonly appear in the real world. Robust, tough, and high-performing for even the most challenging conditions. Alien readers come with advanced filtering and intelligence which benefits users with less network traffic, fewer additional pieces of network equipment, lower setup, and lower maintenance costs.

The ALR-F800 is Alien’s self-optimizing enterprise RFID reader. With a discrete architecture that intelligently adapts and configures based on its environment. The ALR-F800 has the industry’s best Power over Ethernet transmit power and performance. The ALR-F800 has the flexibility for system enhancements and future proofing such as the industry standard MicroSD and USB slots for adding memory along with additional capabilities such as Wi-Fi, Bluetooth, and cellular.

ALR-F800 Features:

- Global EPC Gen 2 platform.

- DSA (Dynamic Self-Adapting) real-time read optimization.

- Alien GateScape ease-of-use.

Power source agnostic and auto-switching.

Power source agnostic and auto-switching.- Automatic inventory optimization.

- Feature-rich Alien Reader Protocol.

- Dynamic Authentication of Higgs ICs.

- Exceptional sensitivity and performance.

- Automode, with on-board state machine.

- High read rates for demanding applications.

- Enhanced noise rejection for reliable data capture.

- RSSI & speed filters.

- Easy RFID software integration.

- Easily configurable and upgradable.

- Industrial, installation-friendly I/O connector.

- Antenna reflection cancellation optimization.

- Supports extended / custom Higgs IC features.

- Auto “Seek” function for low duty cycle applications.

- RoHS EU 2002/95/EC compliant.

- Plenum Rated (EAHS) per UL 2043.

The ALR-F800-X builds on the ALR-F800 with a revolutionary solution that simplifies RFID infrastructure installation, operations, and maintenance. Combines an Enterprise RFID reader and edge service to provide multiple-reader visualization and management. The ALR-F800-X comes with emissary which is Alien’s multi-reader configuration, management, and work-flow description solution. This means users can create names for each reader instead of using the standard serial number that a RFID reader normally identifies by. Making the management of multiple readers easy.

ALR-F800-X Features:

Reader + Multiple Reader Configuration and Management in one device.

Reader + Multiple Reader Configuration and Management in one device.- Class leading Global EPC Gen 2 4-port RFID Reader.

- Same footprint as Alien’s ALR-F800 UHF Enterprise Reader.

- Built in handling of common chores.

- DSA (Dynamic Self-Adapting) real-time read optimization.

- Power source agnostic and auto-switching.

- Feature-rich Alien Reader Protocol.

- Dynamic Authentication of Higgs ICs.

- Exceptional sensitivity and performance.

- Automode, with on-board state machine.

- RoHS EU 2002/95/EC compliant.

- Plenum Rated (EAHS) per UL 2043.

For any questions or a quote on any of your RFID needs, please contact us at Barcodes, Inc.

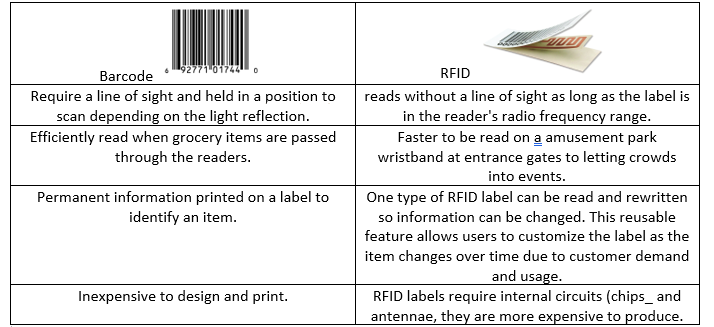

Barcode Vs. RFID: Things to Consider Before You Choose

Barcode and RFID labels are choices that enterprises must choose to improve efficiency. Which are the most cost- effective and reliable in the long run for your operation?

Here are a few things you should consider

Barcodes Vs. RFID

RFID labels have electronically generated unique codes and barcodes use standard protocols. In an inventory collection setting, a barcode label can tally up items in the stock according to product type, manufacturer, and stock level. Employees will have to manually check for item specifics such as color, price, and purchase date of individual items. On the other hand, RFID labels are capable of loading up 2,000 proprietary byte of information and be able to tally up individual items in inventory too.

For example: A barcode label would be able to tell a grocer how many gallons Milk A and Milk B was in the cooler but an RFID label will be able to disclose where each gallon of milk came from the farm and distributor.

Ultimately, if printer properly both barcode and RFID tags can eliminate human error and contribute to enterprise efficiency compare to when items are accounted for by hand. Purchasing either barcode or RFID solutions depends on the depth of data required by an enterprise and how the system will be used in the field. Label consumers have to make a decision based on the needs and financial constraints.

If you need guidance on which solution to choose, feel free to contact one of our dedicated account managers and we will be happy to help.

Metalcraft RFID Assest Tags Printed on SATO CL4NX

Retail Stores are Being Revolutionized with the Help of RFID

Radio Frequency Identification (RFID) are helping retail stores across the country improving customer experience, inventory accuracy, and a way to present wider sets of products to customers who are a little more selective.

Radio Frequency Identification (RFID) are helping retail stores across the country improving customer experience, inventory accuracy, and a way to present wider sets of products to customers who are a little more selective.

RFID Tags have the ability to hold information that identifies the products, its country of origin, materials used, production date, the handling process, and any other important information that took place in the supply chain. Some retailers are using RFID tagging to track products at all of their locations. According to a research study from the RFID Lab at Auburn University, RFID tagging can increase inventory accuracy from an average of 63 percent to greater than 95 percent. This helps enable speed and accuracy for consumers concerning fulfillment for two-day, one-day, or same day delivery. According to Kurt Salmon and the Platt Retail Institute, with RFID tagging, out of stocks can be reduced by up to 40 percent and increase profit margins by 60 percent.

According to the RFID Lab, manufacturers using RFID tagging will see an 80 percent improvement in shipping and picking accuracy, at the same time being able to increase the receiving time by 90 percent. This will allow retailers to communicate more efficiently with their manufacturers for expedited reorders, improved planning, and forecasting of products.

To read more about how RFIDs can help retail stores click here.

For any questions or a quote on any of your RFID needs contact us at Barcodes, Inc.