Take Patient Identification to the Next Level With the Certis® C1-30 Printer

In healthcare, precision and efficiency are non-negotiable. The ability to accurately and quickly print patient ID wristbands is a critical first step of providing high-quality care. The Certis® C1-30 Thermal Patient ID Printer combines reliability, speed, and seamless integration, ensuring healthcare staff can focus on what matters most: their patients.

Keep reading to discover why the Certis® C1-30 is the ultimate choice for patient identification workflows in hospitals, clinics, surgery centers and other care environments.

What Makes the Certis® C1-30 Printer Stand Out?

1. Hassle-Free Performance

With its jam-free design and easy drop-in wristband loading, the Certis® C1-30 eliminates common printing frustrations. Its dependable operation ensures uninterrupted workflows, even in high-demand environments. This keeps your clinicians happy, allowing them to focus on patient care.

2. Seamless Integration

The Certis® C1-30 integrates effortlessly with major electronic health record (EHR) systems, including Epic, Cerner, and Meditech. Its user-friendly setup minimizes IT involvement, making implementation and maintenance a breeze. And, your IT team will love the Printer Utility App, packed with features to help them manage the printer throughout its lifetime.

3. Unmatched Durability

Built with healthcare-grade plastics, the Certis® C1-30 withstands repeated cleaning with harsh disinfectants. Its industrial grade printhead is designed for long-term reliability, ensuring consistent performance over time.

4. Enhanced Patient Safety

By reliably printing wristbands that resist fading, moisture, and alcohol, the Certis® C1-30 ensures accurate patient identification throughout their stay. It pairs with PDC’s industry-leading ScanBand® DR or ScanBand® Soft wristbands, to offer superior durability and comfort.

Ideal for: Busy hospitals, outpatient clinics, and emergency departments.

Product Review: The Certis® C1-30 Thermal Patient ID Printer

At Barcodes, Inc., we specialize in healthcare solutions designed to elevate your operations. The Certis® C1-30 Thermal Patient ID Printer stands out with its combination of innovative features and dependable performance:

- High-Resolution Printing: With 300 dpi resolution, wristbands are crisp, and easy to read and scan.

- Multiple Connectivity Options: USB, Wi-Fi, Ethernet, and Bluetooth ensure compatibility with your existing infrastructure.

- Compact Design: A small footprint (9.1” x 4.4” x 7.3”) makes it perfect for tight spaces. You can also place them on mobile carts or smaller workstations, ensuring your staff can print wristbands when and where they need them.

Conclusion

When it comes to patient identification, the Certis® C1-30 Thermal Patient ID Printer delivers reliability, efficiency, and seamless integration. By streamlining workflows, reducing errors, and enhancing safety, this advanced printer empowers healthcare providers to deliver the best possible care.

Upgrade your identification systems today. Barcodes, Inc. offers expert support to help you implement the Certis® C1-30 and maximize its potential in your organization.

Contact us now to learn more about the Certis® C1-30 Thermal Patient ID Printer.

The Value of RFID in Inventory Management & Supply Chain Visibility

Radio Frequency Identification (RFID) is revolutionizing inventory management and supply chain visibility. While barcodes have been the dominant tool for item identification for decades, RFID offers a powerful alternative with advantages like real-time tracking, non-line-of-sight reading, and faster automation. Although RFID implementation requires more planning and investment than barcoding, it can provide significant efficiency gains for businesses seeking to streamline operations and reduce errors.

Why RFID is Worth Considering

To determine if RFID is the right fit for your business, it’s important to evaluate your needs and operational challenges. Unlike barcodes, RFID does not require line-of-sight to read tags, which makes it ideal for tracking items moving through conveyor systems or stored in hard-to-see locations. The technology also supports varied read ranges, from a few inches to over 10 feet, depending on the tag and reader setup. RFID can be particularly effective when items are traveling at high speeds or are fixed at certain checkpoints.

However, environmental factors must be considered. Items containing metal or liquids can interfere with RFID signals, impacting system performance. Similarly, the choice of fixed or mobile readers depends on whether you need automated scanning at warehouse entry points or manual inventory checks on the move.

Types of RFID Technologies

RFID operates in three main frequency ranges. Low Frequency (LF) systems work well for close-contact applications like ID badges or access control, but their range is limited to a couple of inches. High Frequency (HF) systems can read tags up to 3 feet away, making them ideal for small item tracking and applications like healthcare equipment management.

For supply chain and inventory purposes, Ultra High Frequency (UHF) is the most widely adopted RFID solution. UHF systems offer extended read ranges of up to 10 feet, making them highly effective for item-level and container-level tracking. UHF’s affordability and flexibility have made it a popular choice for businesses looking to manage large volumes of inventory efficiently.

RFID tags are also classified as active or passive. Active RFID tags have their own battery power, enabling long-range and high-speed scanning, but they are costly and bulky. Passive tags, on the other hand, rely on the reader’s signal for power, making them thinner, more affordable, and ideal for product-level tracking in inventory systems.

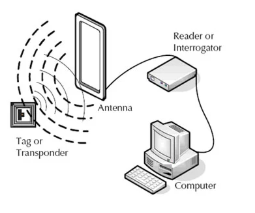

How RFID Works

A typical RFID system includes four key components: tags, antennas, readers, and host software. When a passive RFID tag enters the signal field of an antenna, the tag receives power from the reader. It then “backscatters” its stored data, which is captured by the antenna and processed by the host software. Unlike barcodes, RFID tags can be read even if they are not in direct view or perfectly oriented, enabling faster and more efficient inventory tracking.

The host software uses the captured data for applications such as asset tracking, inventory control, or logistics management. For example, fixed RFID readers can monitor inventory as it passes through warehouse doors, while mobile readers allow employees to conduct manual counts while on the move. Desktop RFID readers offer a plug-and-play option for situations that require reading tags next to a PC, such as retail checkouts or quality control stations.

Challenges and Limitations

While RFID is highly effective, it is not without limitations. Environmental factors such as metals and liquids can interfere with signals, reducing accuracy. Dense collections of items may also pose challenges, as tags in the center may not receive enough signal power to activate. These factors require extensive testing and system design to achieve optimal results.

Additionally, RFID systems involve higher upfront costs compared to barcode solutions. However, businesses that plan carefully and implement RFID effectively often achieve significant long-term savings through reduced errors, improved accuracy, and labor efficiency.

Components of an RFID System

An RFID system begins with the selection of the right tags, which are designed with a combination of chipsets and antennas to store and transmit data. The choice of tags depends on the environment, product type, and read requirements. For high-volume applications, RFID printers simplify the process by encoding tags and printing barcodes as a backup, ensuring data accessibility even if the RFID tag is damaged.

The RFID readers themselves come in various forms. Fixed readers are ideal for automated scanning at checkpoints, such as warehouse docks or conveyor lines. Mobile readers, which resemble handheld computers, are versatile tools for conducting inventory counts and asset tracking across facilities. Desktop readers, though limited in range, offer quick and easy data capture for localized applications.

Finally, middleware software ties the system together. Unlike barcode scanners, RFID readers do not output basic text data directly. Instead, middleware processes the RFID data and integrates it with inventory management or enterprise software. Systems supporting Low Level Reader Protocol (LLRP) ensure compatibility with most RFID readers.

The Benefits of RFID in Supply Chain Management

The greatest value of RFID lies in its ability to enhance efficiency, accuracy, and automation. It enables businesses to track inventory in real time without requiring manual scanning. By reading multiple tags simultaneously, RFID reduces the time and labor involved in inventory checks. Its non-line-of-sight capability allows for greater flexibility, especially in environments where items are stacked, moving, or difficult to access.

Conclusion

RFID technology is transforming the way businesses manage inventory and supply chains by offering faster, more accurate, and automated tracking solutions. While the technology presents challenges, such as signal interference and higher initial costs, the benefits far outweigh these limitations when implemented correctly.

For businesses exploring RFID, it is best to start with a small-scale pilot project, test its feasibility, and gradually scale up. With careful planning and the right resources, RFID can provide unparalleled visibility and efficiency in your inventory management processes, giving you a significant edge in a competitive market.

Revolutionizing Labeling: Latest Advances in Print-and-Apply Technology

Print-and-apply technology is transforming the way businesses handle labeling, offering unmatched efficiency and precision. By integrating a printer with an automated label applicator, this technology streamlines workflows by eliminating manual processes. No longer do employees need to print labels separately and load them into applicators or apply them manually. These all-in-one systems deliver consistent labeling with precise placement on products, envelopes, and packages, boosting productivity and accuracy.

Innovative Print-and-Apply Solutions for Diverse Industries

Today’s cutting-edge print-and-apply solutions are designed to meet the unique challenges of various industries. These advancements provide greater flexibility, speed, and precision to keep up with evolving operational demands.

Ecommerce: High-Speed Labeling for a Variety of Packages

Ecommerce companies must operate at lightning-fast speeds while maintaining accuracy to meet customer expectations. The diversity of package sizes—from slim mailers to oversized boxes—requires adaptable labeling solutions.

Modern print-and-apply machines accommodate a broad range of package sizes with innovative features like applicator tips with wider stroke ranges. These machines can label both flat mailers and tall boxes seamlessly on moving conveyors. Newer models use safer wheel-based designs instead of belts and rely on gravity for label application instead of air puffs, enhancing speed and throughput.

Precision Labeling: Enhanced Accuracy with AI Integration

For businesses where precision is critical, advanced systems ensure consistent labeling for items of the same size traveling on conveyors.

Many systems now incorporate AI-driven vision technology to verify label accuracy. These systems can check for correct serialization, expiration dates, and quality control, identifying and correcting issues like missing characters or damaged labels. The result? Near-perfect labeling accuracy for even the most sensitive use cases.

Automotive: Robotic Label Placement for Complex Surfaces

In industries like automotive, where interior labeling on engine or auto body parts is required, traditional labeling systems fall short. Print-and-apply solutions equipped with robotic arms provide the flexibility to label irregular surfaces or hard-to-reach areas with precision.

Robotic systems also excel at pallet labeling, offering extended reach to apply multiple labels to large, palletized items. Whether it’s the front, side, or both, these systems ensure proper labeling for streamlined operations.

Benefits of Barcodes, Inc Print-and-Apply Solutions

- Boosted Production Rates: Automating labeling and printing accelerates production lines, enabling higher output and efficiency.

- Lower Labor Costs: Automation minimizes manual labor, cutting expenses and optimizing resource allocation.

- Improved Accuracy: AI-driven inspections ensure error-free labeling, reducing costly mistakes and maintaining consistency.

- Unmatched Versatility: Systems handle a wide range of box sizes without manual adjustments, ideal for diverse packaging needs.

- Quality Assurance: Motorized guides deliver precise label placement, ensuring flawless results every time.

Find the Ideal Print-and-Apply System for Your Needs

At Barcodes, Inc. we provide a comprehensive range of automated labeling solutions tailored to your specific applications. Our vendor-neutral approach ensures you get the best system to meet your operational demands for speed, flexibility, and precision.

Take advantage of the latest advancements in print-and-apply technology to boost efficiency, handle diverse package sizes, and achieve robotic precision for interior labeling. Ready to optimize your labeling processes? Contact Barcodes, Inc. today to get started!

How Connected Packaging Powers the Circular Supply Chain

Connected packaging is revolutionizing supply chains, boosting efficiency, and driving sustainability. John Dwyer, Vice President of Digital Innovation at Smurfit WestRock, highlighted the transformative potential of Born-Digital packaging during a guest session hosted by Levata. Barcodes, Inc. is a Levata company.

By combining cutting-edge technologies like traceability, automation, and circular economy principles, Smurfit WestRock is redefining the role of packaging in modern business. Below is an overview of Dwyer’s insights and the impact of Born-Digital packaging on sustainability and supply chain efficiency.

Transforming Supply Chains with Connected Packaging

Traditional supply chains often face inefficiencies, including waste from overstocking. The pandemic exposed these vulnerabilities, emphasizing the need for smarter, connected solutions.

Smurfit WestRock’s Born-Digital packaging integrates advanced technologies like RFID, Bluetooth Low Energy (BLE), NFC, and serialized QR codes into packaging, creating digital identities for products. These innovations enable real-time tracking, improve inventory visibility, reduce waste, and optimize delivery timelines.

For instance, Smurfit WestRock collaborated with a quick-service restaurant chain to track fresh beef throughout its supply chain. By incorporating RFID technology into refrigerated packaging, the company ensured precise, scalable solutions for transitioning from frozen to fresh beef—an essential step for maintaining quality and meeting demand.

Driving Recycling and Sustainability

Sustainability is at the core of Smurfit WestRock’s operations. The company operates 32 recovery facilities in North America, collecting two-thirds of Walmart’s packaging waste and transforming it into new materials. This closed-loop system supports retailers’ ESG goals while reducing waste.

A standout example is Smurfit WestRock’s leadership in the pizza box market, producing approximately 3 billion boxes annually, covering 55% of the U.S. market. Domino’s has introduced QR codes on its boxes to educate customers about local recycling guidelines. Research conducted by Smurfit WestRock confirms that pizza boxes are recyclable, even with food residue, further reducing environmental impact.

Key Trends Shaping Born-Digital Packaging

Several key trends are driving the adoption of connected packaging:

- Real-Time Data Demand: Businesses require instant access to data for better decision-making, particularly in retail and logistics. Connected packaging improves inventory accuracy and supply chain visibility.

- Enhanced Connectivity: Innovations like Wi-Fi 6E and 5G ensure seamless data transfer in harsh environments.

- Circular Economy Integration: Businesses are prioritizing recyclable materials and digital traceability to minimize environmental footprints and meet regulatory standards.

Smurfit WestRock is leading the charge with advanced solutions like light-sensitive sensors that detect unauthorized package openings, enhancing security and trust. By creating scalable, end-to-end systems in partnership with companies like Barcodes, Inc. and SLS, the company ensures seamless integration of sensors, readers, and gateways to address complex supply chain challenges.

Maximizing ROI with Smart Packaging

Connected packaging offers businesses significant returns on investment, often within 12 months. Automating processes like cycle counting allows organizations to redeploy labor to higher-value tasks, reducing costs and improving efficiency.

For instance, smart packaging helps retailers avoid costly penalties for incomplete or late shipments by providing electronic proof of delivery.

A Vision for a Sustainable Future

John Dwyer concluded his presentation by reaffirming Smurfit WestRock’s dedication to the circular economy. Approximately 30% of old corrugated containers in the U.S. are recycled into new packaging, showcasing the company’s commitment to sustainability. As regulations like FSMA and EPR evolve, Smurfit WestRock’s ability to track and recycle packaging will remain a vital tool for achieving compliance and advancing sustainability.

Discover the Future of Packaging

By combining innovation, sustainability, and strategic partnerships, Smurfit WestRock is revolutionizing packaging and creating a smarter, more connected supply chain. Learn how your business can leverage connected technologies, recycling innovations, and sustainable practices to transform your operations and meet evolving market demands.

Contact us today to explore the power of Born-Digital packaging in driving a sustainable, circular economy.

The Critical Role of Accurate Labeling in Healthcare

In the intricate landscape of healthcare labeling is essential to ensure patient safety, streamline operations, and comply with industry regulations. From patient wristbands to medication bottles and lab samples, precise identification minimizes the risk of errors that could have serious consequences. With strict requirements from regulatory bodies, healthcare facilities must implement robust ID and labeling solutions to meet standards for patient care, privacy, and safety.

Label printers specifically designed for patient ID wristbands and healthcare labels offer numerous benefits. These specialized printers are built to handle the unique demands of healthcare environments, ensuring reliable and accurate label production. We’ll examine the top risks in healthcare labeling, and how top performing healthcare label printers play an important role in improved patient safety, streamlined workflows, and enhanced overall operational efficiency.

Top Risks in Healthcare Labeling

Without precise and traceable labeling, healthcare providers face risks that undermine patient outcomes, data integrity, and institutional trust.

- Patient Misidentification: Leading to wrong treatments, surgeries, or medications.

- Medication Errors: Increased risk of adverse drug reactions and treatment failures.

- Specimen Mislabeling: Compromising diagnostic accuracy and delaying treatment.

- Delayed or Lost Specimens: Disrupting laboratory workflow and affecting patient care.

- Regulatory Non-Compliance: Fines and penalties for not adhering to industry standards.

- Increased Liability: Potential for medical malpractice claims and lawsuits.

- Reduced Efficiency: Inefficient workflows and wasted resources due to errors and rework.

- Tarnished Reputation: Negative impact on the healthcare organization’s brand and credibility.

SATO Technology: A Top Performer in Healthcare Label Printing

SATO provides technology solutions that streamline processes from patient registration and discharge to specimen collection, laboratory tracking and verification, as well as pharmacy operations and asset management. Let’s examine three top performers from their lineup: the WS2, the CT4-LX-HC, and the CL4NX Plus.

The ultra-compact SATO WS2 is ideal for crowded healthcare spaces and workstations without sacrificing high performance. The WS2 is perfect for printing patient wristbands and medication labels, maintaining clear, crisp text and barcodes. Made with convenience in mind, the WS2 offers a simple touchscreen interface, and quick, easy media loading to keep patient care moving. Printer highlights include:

- Compact print width of 2.36”

- Up to 7 ips print speed at 203 dpi print resolution

- No-hassle, drop-in media loading

- Easy integration with existing HIS/EMR systems

- USB and Ethernet connectivity

The CT4-LX-HC 4-inch thermal label printer is a powerhouse in a small package that fits seamlessly into even the most crowded healthcare setting. This healthcare printer is clinic-ready with its antimicrobial design and set-up and go connectivity options. The ease of the CT4-LX-HC with its touchscreen operation makes it easy to produce clear, precise labels ideal for patient identification, medication, and lab samples. Printer characteristics include:

- Antimicrobial plastic casing (disinfectant wipe-down ready)

- 4.3” full-color tough screen display

- 8 ips (203 mm/sec) print speed in high-quality 305 dpi print resolution

- Label waste prevention

- Standard USB and Ethernet connectivity, with optional Wi-Fi and BlueTooth

The speedy SATO CL4NX Plus healthcare label printer is designed to meet the rigorous demands of healthcare environments, providing reliability and precision in critical labeling tasks beyond other label printers’ capabilities. Engineered for advanced media efficiency, the CL4NX Plus is best-in-class when it comes to prints produced and minimal maintenance down-time. A unique capability for printing on extra small or RFID labels makes this healthcare printer a champion for a wide range of applications. The CL4NX Plus key features include:

- 14 ips (355 mm/sec) print speed at up to 305 dpi print

- Micro Label print mode (<53mm length)

- Print text and barcodes on RFID tags or labels (UHF, HF, and NFC) while encoding data at the same time

- Extra wide 60-degree print head opening for easy ribbon loading and roller maintenance

- 10-inch media supply and 600m ribbon capacity supported

Conclusion

By prioritizing accurate and reliable labeling, healthcare organizations can significantly enhance patient safety, streamline operational efficiency, and mitigate risks. Investing in high-quality label printers, such as those offered by SATO, empowers healthcare providers to meet stringent industry standards and deliver exceptional patient care. By understanding the critical role of labeling in healthcare and selecting the right technology, healthcare facilities can build a foundation of trust and ensure the well-being of their patients.

Barcodes, Inc. is an expert in error-free data capture and management in the healthcare field. We understand that well implemented healthcare technology solutions can cut down on paperwork and human error, so that you can focus your time where it is needed most – with your patients. Call us today to learn more about all our healthcare technology solutions and how we can help your organization.

The Top 4 Advantages of Multi-functional POS Receipt Printers for Your Business

In an increasingly competitive consumer landscape, customer satisfaction is of paramount importance. If you are a grocery, retail or small business operation, having the right technology in place can make a world of difference. From processing sales transactions to managing inventory and customer service, multi-functional point of sale (POS) receipt printers have emerged as indispensable tools.

Top 4 Reasons to Use Multi-Functional POS Receipt Printers

- Streamline Transaction Processes: Multi-functional printers can significantly speed up checkout processes. Their ability to handle various tasks, such as printing receipts, labels, coupons, and processing checks, reduces the time spent on each transaction. This increased efficiency can lead to shorter wait times, improved customer satisfaction, and higher sales.

- Versatility and Flexibility: These printers are designed to accommodate diverse business needs. For example, multi-functional receipt printers give grocery stores the crucial ability to process various types of transactions, including cash, card, and check payments. In retail settings, features such as barcode printing and detailed transaction reports prove essential.

- Cost Savings: By utilizing highly productive technology, businesses eliminate the need for multiple devices, allowing them to reduce maintenance costs, save paper, maximise space, and simplify their operations. This benefit is especially important to small business operations.

- Improved Customer Experience: Fast and accurate transactions are essential for providing an excellent customer experience that fosters customer loyalty. Multi-functional printers contribute to this by reducing wait times, minimizing errors, and offering personalized receipts.

Product Highlight: Epson OmniLink TM-H6000VI

A perfect example of a cutting-edge, multi-functional POS receipt printer is the Epson OmniLink TM-H6000VI. This advanced printer offers a variety of features that are designed to support the ever-changing needs of modern businesses.

- Fastest In the Industry: The TM-H6000VI clocks-in the fastest print speeds of any multifunctional hybrid printer in the industry at 500 mm/sec, ensuring efficient checkout processes. Its ability to handle multiple payment methods makes it ideal for retail and grocery environments.

- Accurate Check Processing: The TM-H6000VI is capable of robust slip and endorsement printing. It possesses an impressive MICR accuracy of 99.9 percent.

- Durable & Efficient: This EPSON OmniLink printer is built to last with a long-life print head and auto cutter. head life, with printhead reliability of 200 km, as well as extended auto cutter life of 3 million cuts. This performance durability ensures that businesses spend less on maintenance and repairs – an important benefit for small businesses!

- Built Eco-responsible: Doing its part toward sustainability, the ENERGY STAR® qualified OmniLink TM-H6000VI printer is RoHS compliant, is a part of Epson America Inc.’s SmartWay Transport Partner program, and offers end-of-life options. Enjoy cost savings from a 49 percent reduction in paper usage.

- Real-time Remote Monitoring and Management: Ensure optimal performance and stay ahead of maintenance needs with remote access to the printer’s status, maintenance counters, part life expectancy, and settings.

- Multi-platform Support: The OmniLink TM-HV6000VI is compatible with traditional POS terminals, tablets and mobile devices, as well as POS peripherals such as payment terminals and customer displays. With various connectivity options, including USB, Ethernet, and Bluetooth, the HV6000VI is easy to integrate into existing POS systems.

- Online Ordering Capability: Elevate eCommerce operations by optimizing workflow efficiency, reducing errors in order processing, and ensuring timely and accurate deliveries with the Server Direct Print function. The EPSON TM-HV6000VI will retrieve orders from a Web server and print a receipt without requiring integration with POS software.

Conclusion

At Barcodes Inc., we’re more than just a supplier of POS equipment. We’re dedicated to understanding your unique business goals and providing tailored solutions that not only address today’s challenges but also position you for long-term success. If you’re looking for a POS receipt printer, Barcodes Inc. recommends the Epson OmniLink TM-H6000VI as a standout choice that can deliver exceptional performance and value for grocery, retail, and small businesses.

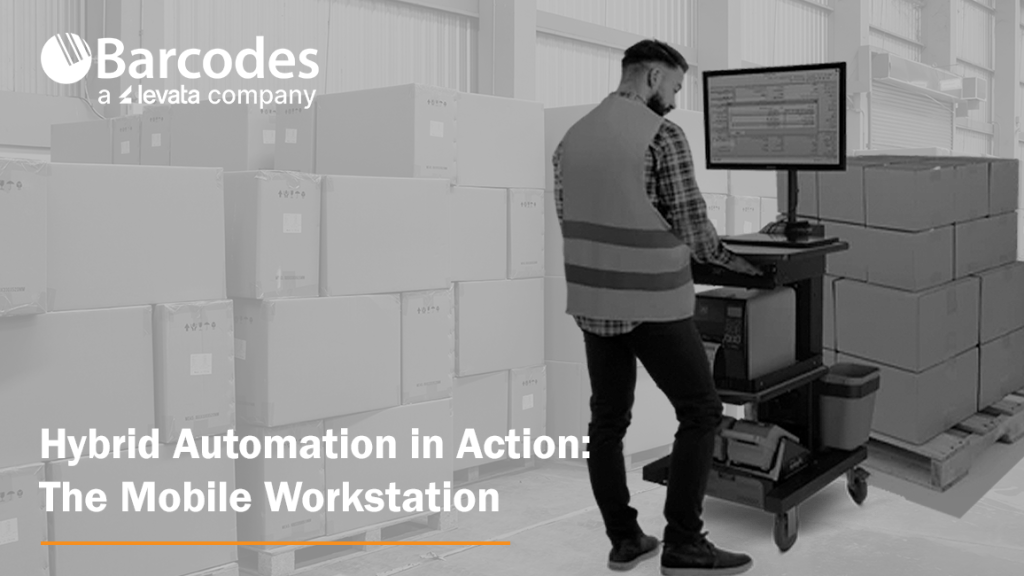

Hybrid Automation in Action: The Mobile Workstation

Hybrid automation has emerged as a powerful approach, blending the strengths of advanced technology and human expertise to create more resilient and efficient warehouse environments. A great hybrid warehouse is characterized by its ability to effectively combine the advantages of automation and human labor, leveraging technology and skilled workers to optimize operations. This synergy not only boosts operational productivity but also supports a workforce prepared for modern operations. Hybrid automation is redefining how workers and technology excel together in modern warehouses by unlocking new possibilities and propelling businesses into a future of unprecedented productivity and growth. Let’s look at the mobile workstation as a case study for how automation through mobility enhances the human workforce.

Why Mobile Workstations Are the Future of Warehouse Operations

Tired of seeing your workforce tied to stationary workstations? It’s time to break free from the chains of inefficiency. Traditional warehouse setups, with fixed computer and label printer stations, can significantly hinder productivity. Workers are forced to spend valuable time walking back and forth, interrupting their workflow and slowing down operations.

A solution like the Newcastle Systems Mobile Workstation is a prime example of mobile technology helping companies embrace hybrid automation. Rather than making the worker walk to and from a stationary workstation multiple times a day, Newcastle’s power carts are helping companies bring the workstation to the worker. Nothing combines productivity, convenience, and ease-of-use like Newcastle Powered Printer Carts. Printing and labeling inventory in warehouses can be a time-consuming process vulnerable to expensive mistakes. Imagine all the wasted time used repeatedly walking back and forth from a stationary label printer to the inventory disbursed across a warehouse, waiting to be labeled.

To truly harness speed and efficiency, a modern, mobile work environment is critical. The Newcastle mobile printer carts double worker output, so you can get the most out of your label printer and your workforce! Workers gain the power and flexibility to print labels where they are needed, while accomplishing more, faster.

The proof of potential:

- 92% Fewer Errors. Bringing print & apply labeling right to the warehouse dock drastically eliminates errors.

- 2X Productivity. By simply outfitting your workers with a mobile workstation, you’ll not only increase their productivity two-fold with no additional manpower needed, but you’ll also see job satisfaction and engagement rise.

- Quick Payback. Companies that invest in Newcastle mobile workstations consistently see a 6–10-month ROI. The benefits continue to grow from there!

- Trimmed Payroll. When print and labeling work is accomplished faster, standard payroll and overtime hours can be significantly reduced.

Leading by Example: How Newcastle Elevates the Human Element of Automation

Providers that value the synergy between human talent and automation technology are crucial in warehouse operations, as they enable a balanced approach that enhances productivity while leveraging the unique strengths of human insight and adaptability alongside automated efficiency. For this reason, Barcodes Inc. values a strong partnership with Newcastle Systems, whose commitment to elevating the human element of automation redefines what efficiency can look like on the warehouse floor and beyond.

Rather than simply focusing on task automation, Newcastle envisions a future where innovative solutions reveal untapped potential in day-to-day operations, bridging the gap between innovative technology and human-centered workflows. At the heart of this approach is their purpose–built mobile power workstations, which bring a flexible, powerful solution directly to workers, enabling them to operate more freely and efficiently.

Driven by a belief that automation should enhance rather than replace human capabilities, Newcastle integrates a “homegrown” philosophy. Their team is immersed in hands-on experience with their products, which helps to develop unique solutions tailored to real-world needs. This dedication ensures that Newcastle’s products go beyond basic functionality, fostering a workplace environment where both technology and human skill are maximized. By focusing on uncovering efficiencies in unexpected places, Newcastle’s vision is not just about meeting industry standards but about setting a new standard for operations that empower every person in the supply chain to thrive?.

Conclusion

Together, Newcastle Systems and Barcodes Inc. are more than just providers of hardware; we strive to be catalysts for operational transformation. By embracing hybrid automation and investing in innovative solutions like mobile workstations, businesses can unlock the full potential of their workforce. This strategic approach fosters a harmonious blend of human ingenuity and technological prowess, driving operational excellence and future-proofing warehouse operations. As we continue to witness the transformative power of hybrid automation, it’s clear that the future of warehouse efficiency lies in the seamless integration of human and machine capabilities.

To learn more about how automation solutions can meet the ever-growing demands for speed, scalability, and flexibility across the supply chain, talk to Barcodes Inc. about our next-generation technology and services. We can help you create next-level modern environments with autonomous mobile robots, machine vision systems, and automatic labeling solutions.

Unlocking Potential: The Impact of Android 13 & GMS on Your Business

The road to unlocking the potential of your business is often an uncharted journey. It can sometimes feel overwhelming to keep up with operations, stay organized, and maintain customer satisfaction and team communications. Luckily, with our technology rapidly evolving, positive impacts can be made on daily operations with Android 13 and GMS. With some automation and a clear road map, you’ll know exactly where you want to go next.

Meet GMS

Google Mobile Services (GMS) is a bundled suite of Google applications and APIs that enhance Android devices. It offers familiar tools like Google Maps, Gmail, and Google Play. Within our POS world, it also leverages tools like access to payment services with Google Pay or ML Kit which provides on-device machine learning APIs capable of barcode scanning or smart replies to suggestions. GMS works with powerful Android 13 to create robust, secure, and customizable solutions tailored to meet the specific needs of your industry.

Restaurants & QSRs

Running a restaurant or QSR takes more than just great food. Keeping everything running smoothly is a huge challenge that businesses face daily. Between orders piling up and miscommunication between front and back-of-house staff, a lot can go sideways. Plus, in our age of convenience, customers’ expectations for quick service are higher than ever. The Touch Dynamics Nexus and Quest Handheld, both powered by Android 13 with GMS, are designed to address these challenges to help businesses streamline operations and improve customer satisfaction to keep them coming back.

Conquer Daily Operations

Juggling the daily chaos of a busy restaurant is a difficult task. The Nexus All-in-One keeps it simple with its sleek, interactive touchscreen that does it all—menus, self-ordering kiosks, or kitchen displays. Mount it on the wall or on a podium to best suit your set-up. Its MediaTek CPU processor keeps things running fast, so orders reach the kitchen instantly, cutting down on wait times.

Streamline & Mobilize

When your restaurant or QSR is packed, your team needs to be able to mobilize. The Quest Handheld lets them take orders on the go and process payments at the table without breaking stride. Multiple payment options—like Ingenico Moby 5500 and ID Tech VP3350—allow for faster transactions and happier customers. Plus, with GMS connectivity, you can stay plugged in throughout the restaurant.

Gaming

The gaming industry comes with its own set of hurdles. Customers want fast service, zero downtime, and seamless experiences across the board. Android 13 with GMS is perfect for these fast-moving environments, giving you the reliability you need and the flexibility your customers expect.

Driving Engagement

Casinos know that lagging tech is frustrating for both customers and employees, and keeping players engaged is the priority. The Quest Gaming Tablet helps you switch between apps and assist customers without a hitch. It’s a real powerhouse—fast, efficient, and always reliable. With its API-driven status lightbar and all-new kickstand, it creates a fun and comfortable gaming experience that keeps players captivated. Wireless connectivity ensures that your favorite games run with no bumps.

Is GMS Right For You?

GMS can help take your business to the next level, especially when combined with a POS solution that suits your needs. If your business relies on mobile payments, Android 13 with GMS can help expedite these transactions while offering security. Businesses that require tailored solutions will find that Android 13’s customizable interface can be fine-tuned to your needs. Finally, if you prioritize being on the cutting edge, Google’s regular updates of Android 13 and GMS ensure you’ll always have access to the latest tech.

Android 13 with GMS presents a unique opportunity to conquer daily operations, streamline & mobilize, and drive engagement across a range of industries. Whether you’re in restaurants, gaming, or retail, these technologies provide the tools to overcome industry-specific challenges. By integrating devices like the Nexus All-in-One, Quest Handheld, or Quest Gaming Tablet, you can unlock the full potential of GMS and stay at the forefront of your field.

Get Started Today

Interested in how Android 13 with GMS on a Touch Dynamic system can transform your business? Contact us today to learn more about how the fully customizable Nexus 21.5″, Quest Handheld, and Quest Gaming Tablet can bring GMS to your fingertips.

Enhancing Warehouse Productivity With Brother’s Mobile Technology

Consider the typical workflow of a warehouse employee: picking items, verifying stock, and printing labels. Currently, employees must locate the item, go to a central location to print the shipping label and packing slip, and then return to the shelf to apply the labels. If this sounds like your warehouse workflow, it’s time to enhance mobility in your environment and improve efficiency.

By embarking on a mobility transformation that includes implementation of mobile printers, scanners, or tablets, employees can complete warehouse tasks directly at the item’s location, saving time and improving workflow. Alternatively, mobile workstations can be introduced to bring technology to more convenient locations, increasing overall productivity. Let’s explore mobile technology solutions that can enhance warehouse efficiency, increase productivity, and provide real-time visibility into inventory levels.

Durable, Portable, and Powerful: The Brother RuggedJet 4

The Brother RuggedJet 4 mobile label and receipt printer raises the industry standard with a smart new way to manage and deploy printers, housing design and market leading technology, performance, ruggedness and connectivity. Quickly print labels and tags up to four inches from handhelds, tablets, and smartphones. Mount these rugged mobile printers in forklifts and vehicles, carry them on shoulder straps, or hook them to belts. Key features of the Brother RuggedJet 4 barcode label printer:

- Remarkably compact design

- Ultra-rugged construction

- Enhanced print speeds of up to 5ips

- Remote updates and configuration

- Smart Li-ion battery lasts a full day shift

- Bluetooth and Wi-Fi connectivity options

- AirPrint using iOS

Flexible Printing Anywhere, Anytime with the Brother PocketJet 8

If portable, full-page thermal printing in the field is a requirements, consider a leader for its high quality prints, impressive speed, and expanded connectivity options, the Brother PocketJet 8. This versatile printer offers a broad range of paper and label capabilities, with everything you need to work efficiently backed by the confidence of lifetime technical support. The PocketJet 8 is smarter, faster, and up for the job wherever it takes you. Key features of the Brother PocketJet 8:

- Up to 300dpi high-resolution print technology

- Print speed up to 13.5 pages per minute

- Single USB-C connection for power and communication

- Operate cord-free via Bluetooth or Wi-Fi

- Print from existing systems with multiple OS compatibility

Conclusion

Mobile technology offers a comprehensive solution to enhance warehouse productivity and efficiency. By implementing mobile printers, scanners, or tablets, businesses can streamline workflows, reduce labor costs, and improve overall operations. With devices like the Brother RuggedJet 4 and PocketJet 8 mobile printers, organizations can enjoy the benefits of portable, high-quality printing wherever they need it. By embracing these innovative solutions, warehouses can stay competitive, meet customer demands, and drive growth.

As your true end-to-end solution partner, Barcodes Inc. has you covered from the assessment and planning phase of your mobility journey, to the support and renewal stages, and everything in between. Contact Barcodes Inc. today to learn more our mobility solutions and more!

Meeting the Challenges of Modern Warehouse Operations

Modernizing warehouse operations has become essential for staying competitive in today’s fast-paced and dynamic market. According to Zebra’s 2023 Warehousing Vision Study, supply chain leaders are increasingly focused on reducing unnecessary tasks and equipping workers with the right tools and technology to streamline operations. Let’s explore the key challenges warehouses face and how innovative solutions can address them.

Key Factors Driving Warehouse Modernization

The rise of e-commerce has significantly impacted warehouse operations, leading to higher shipping volumes, greater demand for inventory visibility, and more returns to manage. Along with this, customer expectations for fast shipping and accurate order fulfillment have soared, intensifying the pressure on warehouses to boost efficiency and stay ahead of the competition. These challenges are compounded by labor shortages, making it crucial for warehouses to offer a worker-friendly environment that retains talent while optimizing workforce productivity through automation.

Automating Repetitive Tasks: Print and Apply Technology

As labor shortages persist, automation is increasingly vital to ensure workers can focus on critical tasks. Barcodes Inc’s Print and Apply systems automate tasks like preparing and labeling boxes, enhancing accuracy and speed while reducing the burden of manual labor. AI-powered machines can take over these routine processes, allowing workers to focus on higher-value tasks that require human attention.

Enhancing Speed and Accuracy: Wearables and Vehicle-Mounted Computers

With increased shipping volumes and heightened consumer demands for quick and accurate order fulfillment, technologies like wearable and vehicle-mounted computers are transforming warehouse operations. These tools add mobility and efficiency to tasks such as order picking, sorting, packing, and put-away. They also prioritize ergonomics, ensuring workers can perform their jobs comfortably and productively, leading to greater job satisfaction.

Providing the Best Equipment: Rugged Tablets and Scanners

Equipping employees with the right technology is crucial for both attracting and retaining workers. Rugged tablets and barcode scanners, designed to withstand the harsh conditions of warehouse environments, are ideal for improving employee performance. These durable devices ensure operational continuity while helping employees work more efficiently.

Streamlining Warehouse Operations with Barcodes Inc’s Solutions

Investing in cutting-edge technology is essential for overcoming the challenges of modern warehouse operations, from managing customer expectations to addressing labor shortages. With decades of industry expertise, Barcodes Inc offers comprehensive solutions, from consulting and project management to procurement, deployment, and device configuration. Our end-to-end services ensure optimal performance, reducing downtime and enhancing your warehouse’s efficiency and competitiveness.