Honeywell Reread Delay and Superior Scanning Speed

Barcodes, Inc. was talking to a customer about the Honeywell Xenon 1900’s blistering scanning speed. We hooked up the scanner and put it in its stand which automatically puts the scanner in presentation mode (scanner scans without a trigger pull). The customer did what customers do all the time – started passing the same barcode underneath the scanner over and over. He was not impressed. The scanner seemed sluggish.

Barcodes, Inc. was talking to a customer about the Honeywell Xenon 1900’s blistering scanning speed. We hooked up the scanner and put it in its stand which automatically puts the scanner in presentation mode (scanner scans without a trigger pull). The customer did what customers do all the time – started passing the same barcode underneath the scanner over and over. He was not impressed. The scanner seemed sluggish.

Here is why – Honeywell programs its scanners to pause for 750 ms (this is the default) before the scanner can reread the same barcode. 750 ms – if my math is correct – is ¾ of a second. This protects against accidental rereads of the same barcode. It can also be used to keep the scanner from reading codes to fast into an application.

Barcodes, Inc. explained this to the customer and told them to turn off Reread Delay if they really wanted to see the scanner fly. We explained that the best way to test scanning speed is to put the scanner into a real life environment or scan different barcodes vs the same one over and over.

In the user guides are barcodes that set the reread delay to 500 ms, 750 ms, 1,000 ms and 2,000 ms. There is even a barcode that allows the user to set their own time.

So why is understanding this so important? It allows your scanner to optimize its scanning speed.

Why Automate Your Picking Solution?

Being right 99% of the time seems like a quality percentage – until you calculate what that 1% actually costs an organization.

Being right 99% of the time seems like a quality percentage – until you calculate what that 1% actually costs an organization.

- Babies born annually in the United States = 3,932,181

- At 99% accuracy 39,322 babies are sent home to the wrong parents

- Prescriptions filled annually in the United States = 4.27 billion

- At 99% accuracy 42.7 million Rx are filled incorrectly

- Distribution Centers pick 250 million units annually

- At 99% accuracy 2.5 million units are picked incorrectly

- That’s almost 7,000 units picked incorrectly every day if working 365 days/year

- At 99% accuracy 2.5 million units are picked incorrectly

Honeywell ESD

You often hear manufacturers reference ESD when discussing scanners. In fact, on the Honeywell Granit datasheet you’ll see under the “Environmental†section on the back: ESD. ±20Kv air discharge, ±8KV contact discharge

You often hear manufacturers reference ESD when discussing scanners. In fact, on the Honeywell Granit datasheet you’ll see under the “Environmental†section on the back: ESD. ±20Kv air discharge, ±8KV contact discharge

What does it mean and why is it important?

- ESD – electrostatic discharge – is the sudden flow of electricity between two objects resulting from two conditions:

- Air Discharge. A high electrostatic field between two objects when they are in close proximity.

- Contact Discharge. Direct contact transfer of electricity between two objects at different potentials. This is similar to the above except you are injecting the shock directly into the computer. A typical example of this would be 20KV Air Discharge into a scanner vehicle mount. The mount in turn passes an 8KV shock to the scanner.

- Kv is a kilovolt – or 1,000 Volts. And a volt is…um…a unit of measurement to define voltage. Think of voltage, using a plumbing analogy, as water pressure.

Three Key Concerns for Barcode Verification

When you hear the term verification in regards to printing barcodes we are referring to much more than just making a readable barcode. Verification is a much more specific requirement for the quality of a 1D barcode or 2D symbol according to an agreed-upon quality standard. Not meeting these standards with your customers, be it Walmart or the DoD, will end up costing you in fines and time lost.

When you hear the term verification in regards to printing barcodes we are referring to much more than just making a readable barcode. Verification is a much more specific requirement for the quality of a 1D barcode or 2D symbol according to an agreed-upon quality standard. Not meeting these standards with your customers, be it Walmart or the DoD, will end up costing you in fines and time lost.

Lucky for all of us we have manufactures like Microscan who make verification easy so you can catch the barcodes that don’t meet the mark before they ever leave your facility. There are essentially 3 main things that can go wrong when printing a barcode that will lead to failing verification.

Honeywell’s Presentation Mode for Scanners

Presentation mode gives customers the ability to scan barcodes without having to squeeze any triggers. You “present†the barcode to the scanner and it scans. Presentation mode uses ambient light and scanner illumination to detect barcodes.

Presentation mode gives customers the ability to scan barcodes without having to squeeze any triggers. You “present†the barcode to the scanner and it scans. Presentation mode uses ambient light and scanner illumination to detect barcodes.

There are two types of Presentation Modes:

- Presentation Mode. In this mode the scanner’s LEDs remain dim until a bar code is presented to the scanner. When a barcode is presented & detected the LEDs turn up, the aimer turns on, and the scanner scans the bar code.  This mode tends to do a better job with bad barcodes.

- Streaming Presentation Mode: The scanner’s LEDs remain fully on and the scanner is always scanning. When a barcode is presented the aimer turns on and the barcode is “scannedâ€. This mode tends to scan good barcodes faster. In Streaming Presentation Mode there is even a Normal flavor and an Enhanced flavor.

- Normal = Good scan speed and the longest working ranges.

- Enhanced = Fastest scan speed but less range.

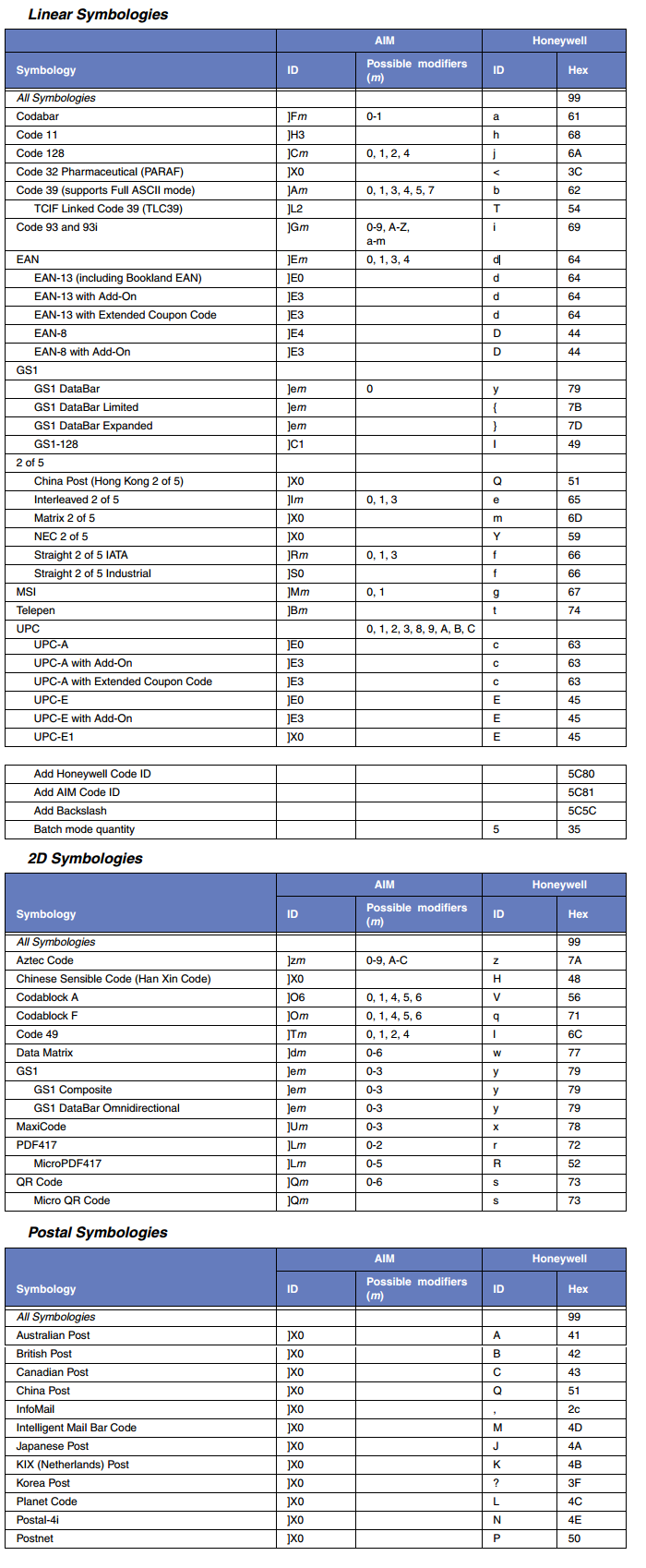

Identifying your Barcode Symbology Type with a Honeywell Xenon of Granit Series Scanner

If you have trouble identifying your barcode types (like me) – here is a trick for you.

- Plug your scanner into your PC.

- Turn on Word.

- Go to page 199 of your Xenon/Granit User’s Guide and scan that barcode titled “Add Code I.D Prefix to All Symbologies (Temporary)â€

- Then scan the barcode in question.

- You’ll see a character in front of the scanned data on your Word doc (or any app that displays scanned data).

- Go to the section of the chart below (Linear, 2D, Postal) then to the fourth column titled “ID†under Honeywell; find your symbol; and your barcode type is in the first column – Symbology.  This chart is also in the back of the Xenon/Granit User’s Guide.

Note: This setting is temporary and will be removed when the unit is power cycled.

Ensuring RFID’s Bottomline Payoff

Whether a business leapt at the opportunity to become one of the first suppliers with RFID tagged products or now finds itself currently being mandated to employ the technology, the implementation costs and the potential rewards are the same.

Whether a business leapt at the opportunity to become one of the first suppliers with RFID tagged products or now finds itself currently being mandated to employ the technology, the implementation costs and the potential rewards are the same.

To maximize the benefits of RFID, it is critical to view its capability to drive business process improvement, increase supply chain efficiency and ultimately improve bottom line results. From this perspective, the up front capital costs for hardware, engineering consulting costs, opportunity costs, ongoing cost of tags and, in a manual environment, labor associated with the RFID tagging of products are deemed a necessary investment.

Rather than merely RFID tagging products to satisfy the requirements of their largest customers, companies can move from seeing RFID deployment as just the cost of doing business to an opportunity to enhance productivity and profitability. Understanding the impact of data collection and tracking as well as data integration is essential to RFID optimization.

“Lux” Explained for Barcode Scanning

The Granit user guide has a performance chart that says – “Granit 1980i/1981i Scanner Typical Performance (200 lux).  So what is this “lux†thing?

The Granit user guide has a performance chart that says – “Granit 1980i/1981i Scanner Typical Performance (200 lux).  So what is this “lux†thing?

Lux is the amount of ambient light in the area. A full sun, no clouds in the sky, summer day would be considered about 100,000 Lux. A completely dark area with no ambient light at all would be 0 Lux. A typical office environment is usually between 500 – 700 Lux. Granit scanner are used typically in a warehouse which are usually dimmer than offices. It would be safe to say that a warehouse would measure about 200 Lux of ambient lighting.

Tips: Sato CL4NX / CL6NX Series Cleaning Maintenance

Simple regular maintenance on your printer can be the key factor in getting the most out of your printer, printhead, and supplies.

The Sato CL4NX and CL6NX series of printers represents their next generation of thermal printers with advanced support for barcode symbologies, character sets and RFID encoding. A product of Sato’s global R&D network the NX Series incorporates value-added features in a world-class design to deliver a printing solution that goes beyond expectations.

Honeywell’s Mobile Phone Mode

There is a mode titled “Hand Held Scanning – Mobile Phone†that optimizes your scanner to read bar codes from mobile phones and other LED displays. It does this in part by flickering the LEDs. Last week a business was having trouble reading barcodes off of his laptop so we told him to turn the feature on (by scanning the barcode). And of course he stopped having trouble. Note that you don’t have to have this feature on when scanning barcodes off of phones/tablets. It just helps the cause sometimes.

There is a mode titled “Hand Held Scanning – Mobile Phone†that optimizes your scanner to read bar codes from mobile phones and other LED displays. It does this in part by flickering the LEDs. Last week a business was having trouble reading barcodes off of his laptop so we told him to turn the feature on (by scanning the barcode). And of course he stopped having trouble. Note that you don’t have to have this feature on when scanning barcodes off of phones/tablets. It just helps the cause sometimes.

I wanted to know what the impact was on scanning speed when scanning regular barcodes when this feature was turned on. So I tested it.

The results – the Xenon 1900 is a little slower (about 15%) with this feature turned on. That sounds like a lot but the difference in speed really isn’t noticeable. The Xenon still blows through my scanner board.

So don’t hesitate to use this feature if the application calls for it – even if other barcodes are being scanned that aren’t on a phone or a computer screen.