Tips: Pairing Your TSP650II BTi with an Apple iPad

Apple MFi certified, Star’s TSP650II BTi receipt printer is the perfect solution to add receipt printing to your iPod Touch, iPhone or iPad based point-of-sale system. With operating system support for iOS, Android and Windows, the TSP650II BTi features the best of both worlds by coupling the comfort of legacy products with the speed and connection options demanded today in fast-paced point of sales environments.

Zebra Labels for Any Application

Label printing isn’t rocket science by any means but knowing what label to use for your specific application can be challenge at first. Zebra has been the leading manufacturer of printers and labels with a wide range of offerings to meet the needs of any environment from very short term temporary shipping labels to rugged, outdoor asset labeling.

Label printing isn’t rocket science by any means but knowing what label to use for your specific application can be challenge at first. Zebra has been the leading manufacturer of printers and labels with a wide range of offerings to meet the needs of any environment from very short term temporary shipping labels to rugged, outdoor asset labeling.

Following these simple guidelines it’ll be easy to determine which type of label you need and the most suitable Zebra options.

Key Benefits of Vehicle Mount Terminals

Look into any mid to large scale warehouse operation and you will see vehicle mount terminals in use to improve efficiencies across the facility. Especially in the case of forklifts, embedding a capable mobile terminal can improve productivity and reduce errors from the docks to the yard. Having access to accurate information at all time in real-time aids in every process from receiving to storing, moving around, cross docking and picking.

Look into any mid to large scale warehouse operation and you will see vehicle mount terminals in use to improve efficiencies across the facility. Especially in the case of forklifts, embedding a capable mobile terminal can improve productivity and reduce errors from the docks to the yard. Having access to accurate information at all time in real-time aids in every process from receiving to storing, moving around, cross docking and picking.

Key Benefits of Vehicle Mount Terminals

- The vehicle terminal tells your driver exactly what items to pick-up

- The driver has detailed information at all times on where to store product such as a bin or rack number and can confirm the putaway is complete

- The terminal can track product in real time while it is being moved within your warehouse or even cross docked for immediate shipping

- The real time accuracy of information right in the vehicle that is picking the product eliminates human error in selecting the wrong product

- AÂ vehicle mount computer than can immediately confirm the right product is being moved onto the right truck for shipping, eliminating human error

FDA Food Traceability with Zebra Labels

Ever since the FDA passed the Food Safety Modernization Act, anyone involved in the food supply chain has to be able to produce, at any moment, the movement of food from supplier to the final retail store.  With legislation forcing food grower, manufacturers, and distributors to track food from field to the dinner table, having capable and affordable traceability technology is essential for everyone involved.

The biggest motivation behind the legislation is to make it easier to trace and find sources of contaminated food to the correct original source. This may seem at first as a measure mainly for the end consumer but it also protect growers and manufactures in being to very precisely remove their goods from suspicion of tainting as opposed to wide spread recalls. The costs involved in a capable barcode tracking system is noticeable less than even just one recall incident.

The Food Safety Modernization Act calls for, among other things, unique identifiers such as the GS1 databar, and full electronic pedigree or origins of the produce. Barcoding technologies are an important first step in this compliance as growers begin to change and update their record keeping methods. This is where Zebra and their wide range of printers and FDA approved labels are the perfect complete solution.

With printer options for low volume small businesses, GK420 and TLP2824 Plus, to high speed/high output models, ZT400Â and 110Xi4, Zebra’s long standing industry experience and expertise is designed in every printer they make. From labeling a single tomato to whole crates and packaged foods, Zebra has a traceability solution that can improve your business’s accuracy and efficiency.

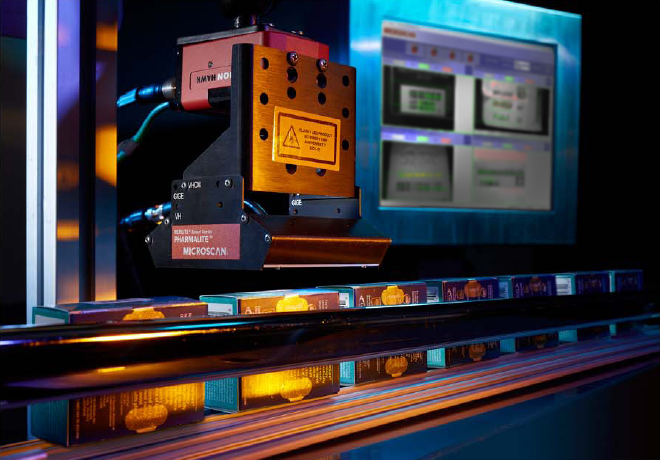

The Most Common Causes of Unreadable Barcodes

Item identification and data acquisition through barcodes is critical to the function of automated operations, from ensuring that the correct components are used in the assembly of a smart phone to recording accurate patient data for samples in a laboratory. When poorly-marked or damaged barcodes result in “no-reads†or failures, loss of data can have disastrous effects on product integrity and corporate reputation – not to mention potential legal implications and serious risks to consumer welfare. Understanding the root cause of unreadable barcodes and using technology appropriately to prepare for or resolve these issues is simple to do and it can mean the difference between success and failure in automation. This white paper describes potential solutions for the most common causes of unreadable barcodes, including:

Item identification and data acquisition through barcodes is critical to the function of automated operations, from ensuring that the correct components are used in the assembly of a smart phone to recording accurate patient data for samples in a laboratory. When poorly-marked or damaged barcodes result in “no-reads†or failures, loss of data can have disastrous effects on product integrity and corporate reputation – not to mention potential legal implications and serious risks to consumer welfare. Understanding the root cause of unreadable barcodes and using technology appropriately to prepare for or resolve these issues is simple to do and it can mean the difference between success and failure in automation. This white paper describes potential solutions for the most common causes of unreadable barcodes, including:

- Low Contrast

- Quiet Zone Violations

- Improper Reading Position

- Print or Mark Inconsistency

- Damage or Distortion

How to Choose the Right Thermal Ribbon for your Label Printer

Thermal transfer printing provides for a longer lasting print as compared to direct thermal printing. The reason thermal transfer prints last longer is due to the use of a thermal transfer ribbon during the printing process. A thermal transfer ribbon is required to obtain a long lasting print. However, choosing the proper thermal transfer ribbon to fit your printer and application can be difficult. Help choosing the correct thermal transfer ribbon has arrived!

Thermal transfer printing provides for a longer lasting print as compared to direct thermal printing. The reason thermal transfer prints last longer is due to the use of a thermal transfer ribbon during the printing process. A thermal transfer ribbon is required to obtain a long lasting print. However, choosing the proper thermal transfer ribbon to fit your printer and application can be difficult. Help choosing the correct thermal transfer ribbon has arrived!

Follow the simple steps below to identify the proper ribbon:

Step 1: Ensure you have a Thermal Transfer Printer

Ribbon is only used with Thermal Transfer printers. A ribbon cannot be used with a Direct Thermal printers as they do not have the proper internal mechanical components to hold or thread the ribbon.

Continue reading »

How Do I Know What Barcode Label I Have?

Barcode labels come in a variety of types and materials to meet the needs of a range of applications. From a temporary shipping label to a rugged asset tag that needs to endure the challenges of outdoor use, there are labels that can meet these needs.

come in a variety of types and materials to meet the needs of a range of applications. From a temporary shipping label to a rugged asset tag that needs to endure the challenges of outdoor use, there are labels that can meet these needs.

Knowing what type of label you are using is almost impossible to tell from just looking at it but there are a few key tests you can conduct to figure out what type and material your label is. Following these steps you can be assured you order the same label your application needs.

1. Try to tear the label in half

If you can tear the label in half we know right away that it’s a paper stock as opposed to a synthetic material like polypropylene or polyester.  Synthetic materials may stretch and deform a bit but will not be tear-able by hand.

Continue reading »

Is ID Card Software Specific to a Printer?

Most ID card printer manufacturers have their own software. Datacard’s TruCredential, Zebra’s ZMotif CardStudio, and Fargo’s Asure ID have various versions and levels of sophistication. All have general design capabilities, and then advance to allow for additional benefits including but not limited to centralized databases, visitor management, and network capabilities. But are the various software choices only compatible with the same brand of printers? The answer is no. The software mentioned above are compatible across brands. Your choice should depend on ease of use and features set. Datacard’s new TruCredential has an extremely easy user-interface and allows you to design process flows for your typical ID needs. The software, recently released, offers the best of multiple Datacard software (ID Works and TruPhoto).

Most ID card printer manufacturers have their own software. Datacard’s TruCredential, Zebra’s ZMotif CardStudio, and Fargo’s Asure ID have various versions and levels of sophistication. All have general design capabilities, and then advance to allow for additional benefits including but not limited to centralized databases, visitor management, and network capabilities. But are the various software choices only compatible with the same brand of printers? The answer is no. The software mentioned above are compatible across brands. Your choice should depend on ease of use and features set. Datacard’s new TruCredential has an extremely easy user-interface and allows you to design process flows for your typical ID needs. The software, recently released, offers the best of multiple Datacard software (ID Works and TruPhoto).

Always feel free to consult an ID professional with any questions on what is the best software for you.

Ribbon Choices for Printing Color on Both Sides of an ID Card

When deciding on an ID card printer purchase, a typical question is whether you intend to print on one side or both sides. Many sellers fail to dig deeper into the problem and ask if you intend to print color on one or both sides of the card.

When deciding on an ID card printer purchase, a typical question is whether you intend to print on one side or both sides. Many sellers fail to dig deeper into the problem and ask if you intend to print color on one or both sides of the card.

If you intend to print color on one side and black on the back, all dual sided printers can offer a ribbon to accomplish that. For example, the Datacard SD360 allows for printing on both sides and the standard ribbon is the YMCKT-KT. However, this choice of printer and ribbon doesn’t solve the need for full color on both sides of the card. If you know that dual sided color printing is the only way you intend to print, a single sided printer (Datacard SD260) with a full color ribbon (YMCKT), where you put the card through the printing process twice is your best bet. The process uses twice as much ribbon as a standard print, but does save you the cost of a dual sided printer.

Until a dual sided color printer becomes available, your best bet is to use a full color ribbon and run the card through the printing process twice. Always feel free to contact one of our ID professionals with any questions on what is the best printer and ribbon combination for you.

Five Things to Know Before Choosing an Embedded Data Acquisition Device

Successful data acquisition for barcode reading or part inspection depends on the ability of the data acquisition device, such as a barcode reader or machine vision camera, to function at peak performance within the restrictions of the application. In applications where barcode reading or machine vision inspection processes are embedded inside of equipment, limited integration space puts a unique set of restrictions on how a device can be installed, not to mention demands on the size and capabilities of the device itself. Before installation, it is important to choose a device with optimal specifications to ensure inspections can be done accurately and consistently throughout the life of the machine. This post outlines the five things an engineer should know before choosing a data acquisition device for embedding into equipment, including:

Successful data acquisition for barcode reading or part inspection depends on the ability of the data acquisition device, such as a barcode reader or machine vision camera, to function at peak performance within the restrictions of the application. In applications where barcode reading or machine vision inspection processes are embedded inside of equipment, limited integration space puts a unique set of restrictions on how a device can be installed, not to mention demands on the size and capabilities of the device itself. Before installation, it is important to choose a device with optimal specifications to ensure inspections can be done accurately and consistently throughout the life of the machine. This post outlines the five things an engineer should know before choosing a data acquisition device for embedding into equipment, including:

- Barcode Type and Orientation

- Inspection Requirements

- Application Speed

- Integration Space

- Data Communication Needs