Thermal Printing Cuts Cost and Adds Value for DSD

An important part of the value of automating direct store delivery (DSD) operations comes from having the ability to give customers delivery receipts, order forms and invoices on the spot. Printing documentation at the time of the visit helps ensure accuracy, reduces paperwork and clerical labor in the back office, and accelerates the cash cycle. In some countries, it is a legal requirement that DSD companies to provide and maintain a printed record of each transaction. The actual value companies can attain by mobile printing depends on the printer itself. For example, the media used in thermal printers typically costs 45 to 50 percent less than multi-part forms used in dot matrix printers, and the total cost of ownership (TCO) for ruggedized mobile printers is 58 percent lower than for non-ruggedized models.

Media cost, reliability, ease of use and compatibility with mobile computers and DSD applications give businesses a lot to think about when selecting a printer to support their operations. The decision is also made challenging because there are more technology and product options than ever. For companies that already use mobile printing in their DSD operations, product choices may have changed considerably since the last replacement cycle. Many first generation DSD automations included a vehicle-mounted dot matrix printer. Today DSD printers can be worn, carried or remain mounted in the vehicle, and thermal print technology is selected for the majority of new and replacement rollouts.

Operating System Strategy for Mobile Computers

After more than a decade of stability using mobile computer operating systems based on successive versions of Microsoft Windows Mobile and its predecessors, the current situation is far more dynamic. Major players in the consumer smartphone market are migrating users to rich interfaces focused on screen interaction rather than keypads. Powerful multi-core processor architectures enable highly responsive applications. The tight integration of sensors, wireless connectivity, and application services frameworks are driving a new paradigm, allowing developers to easily integrate key functionality into their apps via standard system APIs. A large ecosystem has emerged to provide apps, resources, and tools to facilitate development.

But what does this mean for the enterprise? How does a changing user base drive new application interfaces? Which ecosystem should IT embrace for mobile devices? These are questions with no singular answer, yet multiple alternatives are offered for consideration. This paper will outline several options and provide guidance as to which ones may best fit the needs of each individual enterprise.

High Performance RFID Unlocks Your Business Productivity and Profit

To compete effectively in today’s business environment, you need to be more responsive, more nimble and more efficient. To protect ever-thinner profit margins, you need more data, more accurate intelligence and more streamlined processes in less time using less money. Your supply chain is more global and complex, so you need more real-time, error-free inventory and tracking processes to maintain accountability and productivity.

To compete effectively in today’s business environment, you need to be more responsive, more nimble and more efficient. To protect ever-thinner profit margins, you need more data, more accurate intelligence and more streamlined processes in less time using less money. Your supply chain is more global and complex, so you need more real-time, error-free inventory and tracking processes to maintain accountability and productivity.

Enterprises from retail to healthcare/pharmaceuticals are turning to automated RFID systems to gather the business-critical asset and tracking data they need to improve processes, productivity, and profitability. As the need grows for faster, more reliable data collection in hectic business environments, so does the demand for higher performance RFID hardware. Motorola is meeting that demand with a new standard in business-class RFID performance – the Motorola FX7500 Fixed RFID Reader.

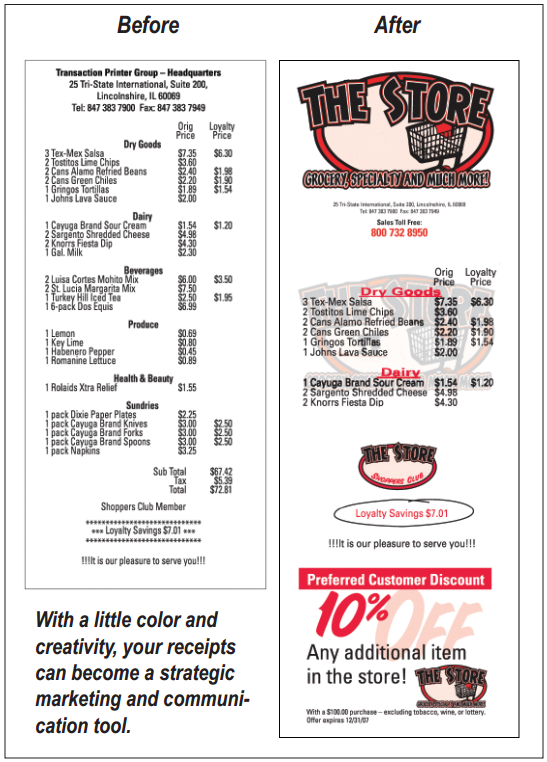

How POS Receipts Build Sales And Loyalty

The coupon revival continues, and the source of those most often redeemed might surprise you.

The coupon revival continues, and the source of those most often redeemed might surprise you.

According to the Annual Topline U.S. CPG Coupon Facts Report for Year-end 2010, released by NCH Marketing Services, Inc., marketers distributed 332 billion coupons for consumer packaged goods last year, marking the largest single year distribution of coupons ever recorded in the United States. Those coupons redeemed totaled $3.7 billion in savings for consumers. Fueled by frugal recession-weary shoppers, coupon usage has climbed from 63.6% in 2007 to 78.3% in 2010, according to NCH.

Most of those coupons distributed— a full 90% — came in the form of free-standing inserts, according to Inmar, the company that handles the bulk of coupon processing in the U.S. But retail marketers take note — that’s not where the leading growth in redeemed coupons lies.

The Checkout Experience and Today’s Shopper

Even though the first bar code scan in a retail store took place over 40 years ago, many people still active in the retail industry remember when bar code scanning at the checkout was a novelty; not the norm it is today. Given the $20,000 price tag of the first grocery store checkout scanner – about $93,000 in today’s dollar – the early technology adopters were truly committed. Although some naysayers probably thought they should have been committed.

Since then, and especially in the last few years, other technologies have been developed and adapted to improve the retail checkout. These developments are getting more attention today because Retailers are focused on the importance of an improved in-store shopping experience for their customers. They are working to keep the in-store experience valuable and relevant as they compete with the online alternatives consumers have at their fingertips.

Successfully Scanning Shipping Container Codes – Application Brief

Intermec has many software-based Imaging Solutions that enable automated data collection when only letters and numbers are present. These imaging solutions take advantage of the enhanced scan engine, camera and optical character recognition(OCR) capabilities present in many Intermec mobile computers. Imaging Solutions are designed to promote the paperless workflow process and improve yard operations.

Intermec has many software-based Imaging Solutions that enable automated data collection when only letters and numbers are present. These imaging solutions take advantage of the enhanced scan engine, camera and optical character recognition(OCR) capabilities present in many Intermec mobile computers. Imaging Solutions are designed to promote the paperless workflow process and improve yard operations.

Scanning Intermodal Container or shipping container codes is one of the imaging solutions offered by Intermec. The ultra-rugged Intermec CK71 mobile computer, with the extended range EX25 scan engine, can withstand the harsh port conditions and long distance scans. The underlying OCR engine was developed in a common language for ease of integration with other applications.

Evaluating Barcode Reading Technologies: Laser vs. Imager

Choosing the right barcode reading technology is fundamental to achieving optimal performance from a data collection solution. As new symbologies and technologies are developed, the choices are more varied than ever. There has been much debate on the merits of laser-based and camera-based barcode readers, and in fact, some have asserted that only image-based readers should be considered for new automation applications.

Should laser barcode scanners be considered “obsolete” technology and are imagers (camera-based readers) the only viable technology for today’s applications? While imagers have seen increased use due to the growing adoption of 2D symbols such as Data Matrix, laser scanners still set the standard for accurate, high speed barcode reading in many applications. The optimal barcode reading solution will be dictated by the specific requirements of an application.

Technical Considerations for Controlling ESD in Electronics Manufacturing

Mastering ESD control has always been critical to achieving high production yields, and it will become even more important in the next few years. While the industry has a solid understanding of ESD safety in manual operations involving personnel, there is room for improvement in automated applications. To be effective, ESD control programs must ensure that automated handling equipment is capable of handling tomorrow’s highly sensitive devices.

The Cost of ESD

ESD impacts productivity and product reliability in virtually every aspect of electronic environment. Despite the effort made over the past decade, ESD still costs the electronics industry billions of dollars every year. Industry experts attribute an estimated 8 to 33% of all product losses to be caused by ESD. The individual cost of these devices themselves range from a few cents for a simple diode to several hundred dollars for complex hybrids. However, ESD damage affects more than just the loss of devices. It affects production yields, manufacturing costs, product quality and reliability, customer relationships, and ultimately, profitability.

Trenor Chooses the Memor Mobile Computer for TOPSHOP and TOPMAN

Overview

Trenor Group is a fashion retailer with a franchise of brand stores. The company was founded in 2000 and is headquartered in Stockholm, Sweden. Thanks to an agreement with British fashion company Arcadia Group Ltd., a British retail giant in fashion, Trenor has a portfolio of many different brands, including the widely known TOPSHOP and TOPMAN.

The Challenge

Both the TOPSHOP and TOPMAN retail stores used a solution for store inventory management that required a lot of work and that was very time consuming. Every time an inventory procedure needed to be performed, someone from the head office would have to bring a laptop with a specific integrated application to each store, along with another terminal for wireless data transfer. These devices needed to be set up for use in the specific store, and the inventory process could finally begin.

Labeling Solutions for Oil Change and Automotive Applications

The simple step of applying oil change reminder labels carries real value for the automotive service establishment and the customer. These labels provide a subtle but persistent notice to the customer of the next service date, helping ensure the vehicle remains in optimal condition. They also remind a satisfied customer where they last received service, increasing the likelihood of return business.

While an enclosed automobile may seem like a relatively benign environment, these labels are subjected to significant environmental rigors. High exposure to ultraviolet radiation can attack labels and adhesive, causing adhesives to harden and leave residue, or causing the label to break apart and delaminate rather than removing in one piece. Temperatures inside a parked car in the summer can quickly reach 140°F, effectively baking the label facesheet and adhesive. During winter, windshields repeatedly cycle between freezing temperatures and heated defrost cycles.