Barcoding News

Data tracking news, product updates, tips, and more

Adoption of Android in Enterprise Mobile Computing

Should your business commit to using or migrating to the Android operating system? Before we answer that we should caveat by stating that no two IT departments are exactly the same. While Android currently holds a small market share of the rugged platform, its flexibility and customizability make it a leading candidate to take over for Microsoft, which has historically dominated the enterprise space. Microsoft’s software constrainment after each release has pushed the large device manufacturers like Zebra (formerly Motorola) and Honeywell to start investing heavily into the Android operating system for their mobile computers. The rest of the manufacturers have started to follow suit. Furthermore, despite the large market share of iOS in consumer devices, Apple is currently the least suited for the enterprise mobility space due to its lack of customization and restricted API access. See below for a chart that depicts the biggest benefits of Android in enterprise mobility:

Should your business commit to using or migrating to the Android operating system? Before we answer that we should caveat by stating that no two IT departments are exactly the same. While Android currently holds a small market share of the rugged platform, its flexibility and customizability make it a leading candidate to take over for Microsoft, which has historically dominated the enterprise space. Microsoft’s software constrainment after each release has pushed the large device manufacturers like Zebra (formerly Motorola) and Honeywell to start investing heavily into the Android operating system for their mobile computers. The rest of the manufacturers have started to follow suit. Furthermore, despite the large market share of iOS in consumer devices, Apple is currently the least suited for the enterprise mobility space due to its lack of customization and restricted API access. See below for a chart that depicts the biggest benefits of Android in enterprise mobility:

FDA Food Traceability with Zebra Labels

Ever since the FDA passed the Food Safety Modernization Act, anyone involved in the food supply chain has to be able to produce, at any moment, the movement of food from supplier to the final retail store.  With legislation forcing food grower, manufacturers, and distributors to track food from field to the dinner table, having capable and affordable traceability technology is essential for everyone involved.

The biggest motivation behind the legislation is to make it easier to trace and find sources of contaminated food to the correct original source. This may seem at first as a measure mainly for the end consumer but it also protect growers and manufactures in being to very precisely remove their goods from suspicion of tainting as opposed to wide spread recalls. The costs involved in a capable barcode tracking system is noticeable less than even just one recall incident.

The Food Safety Modernization Act calls for, among other things, unique identifiers such as the GS1 databar, and full electronic pedigree or origins of the produce. Barcoding technologies are an important first step in this compliance as growers begin to change and update their record keeping methods. This is where Zebra and their wide range of printers and FDA approved labels are the perfect complete solution.

With printer options for low volume small businesses, GK420 and TLP2824 Plus, to high speed/high output models, ZT400Â and 110Xi4, Zebra’s long standing industry experience and expertise is designed in every printer they make. From labeling a single tomato to whole crates and packaged foods, Zebra has a traceability solution that can improve your business’s accuracy and efficiency.

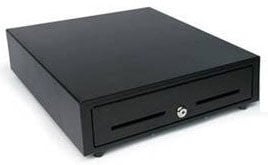

Star’s New CD3 Series Cash Drawers

Star has announced its new ‘Tradition’ cash drawer series with the release of the CD3-1313 and CD3-1616 cash drawer models. The new cost effective cash drawers integrate seamlessly into any retail or hospitality environment with a standard printer communication interface and bottom exit cable, hidden from the customer’s view. With cash till options for both models, the CD3 traditional cash drawers can accommodate to Canadian, United States, and Latin American currency types of 3Bill-5Coin, 4Bill-5Coin for CD3-1313 and 4Bill-8Coin, 5Bill-8Coin for CD3-1616.

Star has announced its new ‘Tradition’ cash drawer series with the release of the CD3-1313 and CD3-1616 cash drawer models. The new cost effective cash drawers integrate seamlessly into any retail or hospitality environment with a standard printer communication interface and bottom exit cable, hidden from the customer’s view. With cash till options for both models, the CD3 traditional cash drawers can accommodate to Canadian, United States, and Latin American currency types of 3Bill-5Coin, 4Bill-5Coin for CD3-1313 and 4Bill-8Coin, 5Bill-8Coin for CD3-1616.

Features include a black stainless steel front drawer cover, dual media slots, and a three function lock system. The smooth black coated finish provides a unified appearance and complements the connected POS peripherals for merchants. The dual media slots provide extra storage for checks and large bills. For security, the key lock at front center allows for an easy manual release with a key or an electronic release.

Clean Start Ribbons for Easy Printhead Maintenance

A printer’s printhead may be the most critical component to ensuring crisp, consistent and readable barcodes. Many times the reason prints are not sharp is due to a dirty printhead. BarcodesInc has partnered with IIMAK to provide ribbon with Clean Start. Ribbon including Clean Start allows the user to clean their printhead every time ribbon is changed. Cleaning the printhead on a regular cadence increases the longevity of the printhead.

A printer’s printhead may be the most critical component to ensuring crisp, consistent and readable barcodes. Many times the reason prints are not sharp is due to a dirty printhead. BarcodesInc has partnered with IIMAK to provide ribbon with Clean Start. Ribbon including Clean Start allows the user to clean their printhead every time ribbon is changed. Cleaning the printhead on a regular cadence increases the longevity of the printhead.

Clean Start provides hassle free printhead cleaning with 3 simple steps and only takes 6 seconds.

- Load the Clean Start Clean Start is built right into most BCI thermal transfer ribbons.

- Lock the printhead

- Pull Clean Start

- Your printer’s printhead has just been cleaned.

When using Clean Start, unnecessary interruptions caused by printhead failures, can be avoided. This results in less money and time being spent replacing printheads. Contact your knowledgeable BarcodesInc Account Manager for a FREE SAMPLE, of ribbon with Clean Start.

The Most Common Causes of Unreadable Barcodes

Item identification and data acquisition through barcodes is critical to the function of automated operations, from ensuring that the correct components are used in the assembly of a smart phone to recording accurate patient data for samples in a laboratory. When poorly-marked or damaged barcodes result in “no-reads†or failures, loss of data can have disastrous effects on product integrity and corporate reputation – not to mention potential legal implications and serious risks to consumer welfare. Understanding the root cause of unreadable barcodes and using technology appropriately to prepare for or resolve these issues is simple to do and it can mean the difference between success and failure in automation. This white paper describes potential solutions for the most common causes of unreadable barcodes, including:

Item identification and data acquisition through barcodes is critical to the function of automated operations, from ensuring that the correct components are used in the assembly of a smart phone to recording accurate patient data for samples in a laboratory. When poorly-marked or damaged barcodes result in “no-reads†or failures, loss of data can have disastrous effects on product integrity and corporate reputation – not to mention potential legal implications and serious risks to consumer welfare. Understanding the root cause of unreadable barcodes and using technology appropriately to prepare for or resolve these issues is simple to do and it can mean the difference between success and failure in automation. This white paper describes potential solutions for the most common causes of unreadable barcodes, including:

- Low Contrast

- Quiet Zone Violations

- Improper Reading Position

- Print or Mark Inconsistency

- Damage or Distortion

Automating Transportation and Logistics

Logistics accuracy and timing is critical to customers. If you’re a business and deliver the wrong item or fail to deliver it on-time then you have likely lost that customer’s business. To achieve a right first-time delivery we recommend automating your collection and delivery processes to incorporate mobile computers, wearable computers and other barcode equipment, along with our software solutions. Check out some logistics areas that can be automated to provide a more accurate and quicker process that ensures a better customer experience.

Logistics accuracy and timing is critical to customers. If you’re a business and deliver the wrong item or fail to deliver it on-time then you have likely lost that customer’s business. To achieve a right first-time delivery we recommend automating your collection and delivery processes to incorporate mobile computers, wearable computers and other barcode equipment, along with our software solutions. Check out some logistics areas that can be automated to provide a more accurate and quicker process that ensures a better customer experience.

- Sortation and Vehicle Loading – Sorting and loading the right packages is critical for delivery accuracy. Any failed delivery or return results in a cost to the business. With our wearable mobile computers and voice-based software, you can more quickly and easily sort and load packages for first-time accurate delivery. This technology is an evolution from the traditional conveyor system.

- Dispatch – Hundreds of thousands of dollars are lost each year on fuel costs that are a result of ineffective routes and delivery scheduling. Our route planning solution can provide your business with continuously optimal reliable routes while using fewer trucks, miles and drivers. It also enables real-time appointment scheduling in order to keep fleet operations productive and profitable while increasing customer satisfaction.

- Delivery and Collection – Confirmation and proof of delivery is the final element of item tracking. However, many times package deliveries cannot be confirmed due to lost paperwork. Using a mobile computer and point of delivery software allows a driver to capture a signature and confirm the proof of delivery. Additionally, many mobile computers come equipped with GPS to where drivers are at all times and if they arrived at said location.

- Driver De-brief and Vehicle Checks – Missing paperwork, illegible handwriting and sorting through dozens of paperwork can make collecting manual data from drivers a nightmare. With our technology, we have the ability to transform paper documents into an automated form that is accessible through a mobile computer. Additionally, having a telematics system in each vehicle allows for vehicle information to be digitally synched and tracked. Not only does it reduce the need for somebody to transfer manual data into a computer but it also dramatically reduces the amount of time a driver needs at the end of his day for his de-brief.

For more information on how Barcodes, Inc. can automate your transportation and logistics processes give one of our experts a call to get a free consultation for your logistics solutio n.

Label Adhesive Breakdown

Label come in many sizes, shapes and materials. Labels also have several options of adhesives. Although size and material is important, the type of adhesive a label contains can be critical to the success of the label in the desired application. Consider the following choices when selecting the proper label:

Label come in many sizes, shapes and materials. Labels also have several options of adhesives. Although size and material is important, the type of adhesive a label contains can be critical to the success of the label in the desired application. Consider the following choices when selecting the proper label:

- Removable Labels: These labels are designed to be removed from the surface they are applied to. The labels will adhere to most dry, clean surfaces. The benefit of this label is that the label can be completely removed from the surface without damage to the surface or excess adhesive residue/ label flaking during the removal process.

- Permanent Labels: These labels are designed to be non-removable. Ideal for application where the label needs to withstand a long amount of time on a surface and where the label cannot be removed with out being damaged. Shipping a box, warehouse signage or asset tracking are a few applications where a label with a permanent adhesive would work best.

- High-Tack Labels: These labels are designed to also be non-removable. However, the difference is that these labels can withstand higher levels of abrasion, outdoor environments (water and UV resistant) and locations where the label may come in contact with chemicals.

- All-Temp Labels: These labels can be used in several different applications where the labels may be moved from a hot to cold location. Moving inventory from a cold climate to a hot climate is an ideal application for this type of label. These labels are not intended for extremely high temperature applications.

- High-Temp Labels: These labels are designed to be used in environments or applications that may expose the label to extremely high temperatures.

Choosing the proper adhesive is crucial to the success of the label. Reach out to your knowledgeable BarcodesInc sale representative for more information on which label is correct for your application.

Automating Your Retail Store

When speaking to representatives of retail chains, it’s interesting to see how many businesses automate many different areas of the store. Some have a fully automated warehouse system while others have the most modern point of sale system. However, the most successful retail stores have the ability to track an item end-to-end from the moment it hits the dock door to the point of purchase and it leaving the store exit. Below we will walk you through a list of automated retail functions that will improve inventory, shelf replenishment, customer experience and point of sale through an easily automated barcode technology that incorporates mobile computers, barcode scanners, point of sale systems or other barcode equipment, along with our software solutions.

Introducing Printronix’s New T8000 Industrial Thermal Printer

Understanding customers, their needs and the environments they operate in is Printronix’s formula for creating better printing solutions. The latest groundbreaking result to this process is the new Printronix T8000 premier industrial thermal printer. The T8000 exceeds the requirements of the most demanding mission critical manufacturing and distribution operations, offering:

Understanding customers, their needs and the environments they operate in is Printronix’s formula for creating better printing solutions. The latest groundbreaking result to this process is the new Printronix T8000 premier industrial thermal printer. The T8000 exceeds the requirements of the most demanding mission critical manufacturing and distribution operations, offering:

Ease of Use

- New 3.4″ full color display panel with easy to use navigation keys

- Most extensive library of print emulations in the industry, now includes Postscript/PDF printing

- Intuitive printer setup, print quality, and self-help wizard

Industrial Performace

- Seamless integration &connectivity with robust remote printer management

- 40% faster print speed, 6x faster processing speed, and 8x more memory than the competition

- Rugged design for the most demanding global customers and the harshest environments

100%Â Verifiable Output

- Eliminate compliance fines and chargebacks with Online Data Validator (ODV) to produce 100% scannable barcodes every time

- Automatic capture of statistics that can be used as certification stamp and audit

- Fully integrated solution with the ability to retract, void, and reprint labels automatically

For assistance finding the right Printronix printer to meet your needs, contact a printer specialist at Barcodes, Inc

Automating Your Warehouse

Do you still manually track the data and items that are moved in and out of your warehouse? Did you know that barcodes can maximize inventory throughput, increase productivity and improve accuracy throughout different operational areas of the warehouse? Below we will walk you through a list of warehouse functions that can easily automated using a mobile computer, barcode scanner or other barcode equipment, along with our warehouse management software.

Do you still manually track the data and items that are moved in and out of your warehouse? Did you know that barcodes can maximize inventory throughput, increase productivity and improve accuracy throughout different operational areas of the warehouse? Below we will walk you through a list of warehouse functions that can easily automated using a mobile computer, barcode scanner or other barcode equipment, along with our warehouse management software.