Barcoding News

Data tracking news, product updates, tips, and more

Zebra RW420 Mobile Printers Help Ensure Safe Roadways for the Oregon Department of Transportation

Challenge

Challenge

The Oregon Department of Transportation‘s Governor’s Office of Highway Safety (ODOT) was established in 1969 to provide a safe, efficient transportation system that supports economic opportunity and livable communities for Oregonians. As part of its mission, ODOT is constantly researching innovative technology and the latest trends in transportation to help the organization continue to keep the roads safe for all citizens.

That’s how ODOT discovered the APS PocketCitation software, an innovative electronic citation system from Advanced Public Safety (APS), designed to automate and streamline the process of issuing traffic tickets.

Based in Deerfield Beach, Fla., APS develops innovative technology solutions specifically designed to address the challenges of today’s public safety agencies. It focuses on creating software that operates in conjunction with the mobile computers and handheld devices utilized by law enforcement, corrections, fire and EMS personnel. APS products work with an agency’s existing technology infrastructure to significantly increase officer safety and productivity.

Previously, traffic citations were manually issued by the officer, who was required to write out a multi-part form. There were four colored copies of each citation, with a copy given to each party involved—the officer, violator, court and department of motor vehicles. Although each entity had the same information, the police department, court and motor vehicle bureau had to re-enter the data into their own computer systems before it went on the driver’s record.

“This process was redundant and time consuming,†said Steve Vitolo, program manager of Statewide Law Enforcement and Judicial Programs, Oregon Governor’s Office of Highway Safety.

Problems also occur when the driver can’t read the officer’s handwriting on the ticket. If the defendant cannot read the court date because the print is faded or not easily read, the defendant will fail to attend on the proper court date. The need to write slowly and press hard also increased the time it took for the officer to write each citation.

In addition, there were issues related to officers recording the wrong court date. Police officers—who work from their vehicles—didn’t always have a calendar at their disposal and sometimes wrote court dates on holidays when the court was closed. This would automatically result in a dismissal due to officer error.

Solution

According to Jeffrey D. Rubenstein, founder and CEO of APS, approximately 20 to 30 percent of all hand-written traffic citations are dismissed because of incorrect statute numbers, illegible handwriting and other administrative data errors. PocketCitation’s on-board intelligence solves these problems by ensuring that the citation information entered is correct and that the citation itself is printed in clear, legible type by Zebra RW 420 mobile printers.

Northeast Medical Center Uses Bar Coding to Increase Patient Safety

Challenge

Challenge

Since 2000, Northeast Medical Center, a 457-bed acute-care hospital in Concord, North Carolina, has been concerned by the need to improve patient safety, a problem dramatically illustrated in reports issued by the Institute of Medicine, the Joint Commission on Accreditation of Healthcare Organizations (JCAHO), and others, in which medical errors were cited as a central factor in the deaths of between 44,000 to 98,000 U.S. hospital patients annually. Northeast considers itself an early adopter of healthcare technologies, and quickly identified technology as a key element of its renewed commitment to address patient safety.

Larry Hinsdale, Northeast’s CEO, championed an initiative to address patient safety quickly. After considering several alternative solutions, including computerized physician order entry (CPOE) and electronic medical records (EMR), Northeast decided a bar code system would be the most cost effective, manageable patient safety solution, and would yield a collateral benefit to the hospital’s marketing efforts. Northeast began work on a bar code system directed at reducing errors in both phlebotomy specimen collection and in medication administration.

Specimen labels had been printed in batch by printers that were shared and that frequently malfunctioned or produced unreadable bar codes. Batch-printed labels were sometimes applied to the wrong sample. “Each unit had a single printer that was shared between all nurses—a situation that invariably led to errors in labeling,†said Vicki Cooke, Northeast’s expert on nursing information technology systems

Solution

The system went live less than eight months after planning began. The Northeast Medical Center IT department advocated a switch from batch to on-demand printing for specimen collection. Compact Zebra printers are now mounted on a cart along with a laptop. Nurses bring the cart to the patient and produce bar code identification labels when samples are drawn. The labels are applied to the specimen collection tubes, which are color-coded to correspond to the appropriate lab tests. To boost patient safety in medication administration, Northeast now individually packages and bar codes drugs in its pharmacy. Using a laptop mounted on a cart, the nurse scans a bar code on the patient’s identification wristband to pull up the list of drugs to be administered to that patient. The nurse then scans the bar code on the drug to verify that the correct drug is about to be given to the correct patient. The patient’s drug administration record is then electronically updated.

Results

The bar coding system was such an immediate success that all 26 nursing units were equipped with the bar code technology by March 2003.

Methodist Medical Center Uses Bar Coding to Reduce Errors

Challenge

Challenge

In 1999, Methodist Medical Center in Peoria, Illinois, recorded an incidence rate of five adverse drug events (ADEs) per 10,000 doses of medications administered. At the same time, the Institute of Medicine released its report “To Err is Human,†which highlighted an alarming rate of patient deaths due to preventable medical errors, thus reinforcing the urgency to implement an automated system to reduce the risk of potential ADEs.

Solution

That same year, Methodist’s new chief executive officer, Michael Bryant, formed an executive IT steering committee to find solutions to the patient safety issue. “The bar coding strategy was selected because it provides the opportunity to close the loop of medication ordering and administration, and offers the added benefit of providing a second check for nurses,†said Tom Rippeto, Methodist’s chief information officer. The bar coding system also offered a more accurate, less subjective method of capturing and reporting medication errors.

Picking and Printing on the Go

Challenge

Challenge

A Midwestern distribution center knew that it was losing valuable time in its picking operations. To fill an order, the forklift driver would receive a printed pick list from the shipping office and then drive through the distribution center to pick up the listed pallets. Once he had completed the picking operation, he would return to the shipping office to pick up the required shipping labels based on the number of cartons on each pallet. There had to be an easier way.

Solution

The company now uses bar coding throughout this process to automate the development of the pick list, ensure picking accuracy and prepare items for shipping. Forklift-mounted Zebra® portable printers enable the forklift driver to print on-demand shipping labels— saving the trip back to the shipping office.

Otis Elevator Company Keeps Things Moving with Zebra Barcode Printers

Life in a Global Distribution Centre

Life in a Global Distribution Centre

Otis’s Gien-based manufacturing plant has been in existence since 1961. The site comprises several operations including cabin system manufacturing; door system manufacturing, for which the Gien site is the world’s leading production center; a research center employing 100 people; and a distribution center. The distribution center presented the greatest problems in terms of depot management. Due to the size and layout of the site and the complexity of procedures that had developed over time it was very difficult for staff to track and follow up incoming and outgoing consignments. Available storage was inadequately utilized, being determined largely by what space was available in the warehouse. On top of that a significant proportion of data entry was done manually. The reliance on paperwork distributed throughout the process increased the number of errors that arose. Paperwork was produced to assist in information sharing between forklift truck operators for storage, and administrators for data entry.

Product Identification

Even though there is a catalog of standard equipment, a lift is almost always manufactured to bespoke requirements. Components from two different orders cannot be switched, even if they are identical, so errors of labeling, handwriting, data entry, reading the order number or storage location could lead to packages being misplaced or overlooked which has a potential knock- on effect for quality and delivery times for the customer.

Until Spring 2000, operators at the end of the production lines at Otis identified packages manually, detailing information on the project number, the number of packages and the weight. The distribution center was organized around a production management and commercial management software package that did not allow for true tracking and tracing, or for storage optimization.

Otis began the search for a solution to give systematic identification, by product line or by supplier, of all packages passing through the depot. Otis called on IDEM, a specialist integrator in the field of automatic identification and data acquisition, to implement the new equipment. They used 3I for the warehouse management software package and Teklogix for the radio frequency component.

Microscan announces world’s first fully integrated liquid lens barcode imager

Microscan, a global technology leader for precision data acquisition and control solutions, premiers the QX Hawk, the world’s first barcode imager to be fully integrated with liquid lens technology, enabling infinite focus flexibility. The QX Hawk imager easily reads any barcode or 2D symbol, including challenging 2D direct part marks (DPM), within seconds of installation.

Microscan, a global technology leader for precision data acquisition and control solutions, premiers the QX Hawk, the world’s first barcode imager to be fully integrated with liquid lens technology, enabling infinite focus flexibility. The QX Hawk imager easily reads any barcode or 2D symbol, including challenging 2D direct part marks (DPM), within seconds of installation.

With the introduction of the QX Hawk fixed-mount imager, Microscan now has the largest product line available of specialty imagers and verifiers focused on direct part mark reading. The revolutionary QX Hawk is the first high performance imager to have the full flexibility to read any mark at any distance and speed in any environment, and the first to fully integrate liquid lens technology. Advanced imaging technology, including liquid lens autofocus and modular zoom optics, removes the need for automation engineers to research multiple configuration options before deployment.

Honeywell Dolphin 6100 Mobile Computer Introductory Video

Watch this video for a quick overview of features available in Honeywell’s new Dolphin 6100 mobile computer.

Â

Motorola AP-7131 Access Points and RFS6000 Wireless Switches Improve Patient Care and Wireless Security at Medical Center

802.11n wireless network delivers gap-free security, field-proven reliability for critical healthcare applications, and support for current and future end-to-end mobility initiatives

802.11n wireless network delivers gap-free security, field-proven reliability for critical healthcare applications, and support for current and future end-to-end mobility initiatives

The Enterprise Mobility Solutions business of Motorola, Inc. announced its 802.11n wireless LAN (WLAN) solution has been deployed at Memorial Medical Center (MMC) of Western Michigan, a community hospital located in Ludington, Mich.

Motorola’s innovative WLAN technology will enable end-to-end voice, video and data mobility across the entire healthcare facility, helping improve patient care, boost productivity and increase staff satisfaction. Patients and guests will also benefit from the new 802.11n wireless network by gaining high-speed Internet access, so they can stay connected while visiting the hospital.

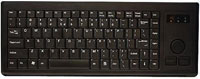

Cherry Increases its Industrial Line with J84-4300 “WipeKey” Washable Keyboard

Cherry’s new J84-4300 “WipeKey” Cleanable keyboard addresses the growing need for cleanable keyboards in industrial, medical and institutional environments.

Cherry’s new J84-4300 “WipeKey” Cleanable keyboard addresses the growing need for cleanable keyboards in industrial, medical and institutional environments.

A study published in “Infection Control and Hospital Epidemiology” journal found germs on keyboards in the healthcare environment to be common. Data from the report suggest that keyboards can be successfully decontaminated with disinfectants, and report authors recommend that “Keyboards should be disinfected daily or when visibly soiled or if they become contaminated with blood.”

Cherry’s “WipeKey” keyboard is resistant to moisture because of its rubber membrane design and moisture drain pattern. However, it offers the tactility and speed typing of a typical notebook keyboard.

WipeKey provides 10 million keystroke endurance in a compact, low-profile package of 14.5″ x 5.5″ x 0.75″. Its integrated rubber pointing device is also rated to IP55 for resistance to liquids and dust. The standard version is equipped with USB interface. It is ideal for applications in diagnostic equipment, medical carts, laboratories, factories and schools.

Efficiency gains that support legal requirements with Zebra’s QL 320 printer.

The challenge:

The challenge:

Acquire information from existing barcodes

Print labels easily and on demand

The solution:

Combine the opportunities brought by Zebra’s QL 320 mobile printer and Falcon 320 mobile terminal

Add printing options to Falcon 320 software

The results:

Compliance with labeling regulations Savings on staff time Flexible and time efficient label printing

The challenge

AHOLD Czech Republic’s aim was to improve labeling of pre-packaged meat products in their stores. On receipt of these meat products they only had one label indicating weight. Ahold also used to add an extra price label using a weighing machine.

In order to consolidate information on both these labels, Ahold had to change the way of attaching price labels. The only solution was to scan weight information from the original label and print a new price label based on the original weight.