Mobile Shelf Price Auditing for the Retail Environment

Industry Need

Aggressive pricing and promotions drive success in retail, and modern consumers are more price-sensitive than ever. The pressure to act and react quickly in modifying pricing continues to escalate. To meet this demand, today’s retailer needs increasingly efficient ways to implement accurate pricing changes on the retail floor. Only Intermec provides the total package of mobile printers, mobile computers, bar code scanners, and durable media necessary to label products and shelves at the point-of-use—key to improving store efficiency and eliminating costly errors.

When prices change, it is critically important that the price on the shelf matches the price in the computer; when these do not agree, significant problems result. If the charged price is higher, customer satisfaction plummets. If the charged price is lower, profits are lost. As an added consequence, retailers regularly incur fines when pricing accuracy laws are violated.

Printing today is commonly completed in batch mode using a fixed printer located in a back room away from the retail space. These shelf labeling systems separate a batch printing process from the point of labeling, creating the potential for obsolete, inaccurate, or misplaced shelf labels. Additionally, this separation from point-of-use leads to wasted trips and introduces a greater chance of human error in mis-labeling. For all these reasons, mobile label printing is becoming increasingly popular for shelf and product labeling in the retail environment.

Continue reading »

Mobile Medical Sample Labeling

Industry Need

Medical testing provides key information to physicians, serving as a foundational tool for diagnosing patient conditions. Accuracy is critically important; mistakes can lead to undiagnosed illnesses or inappropriate treatments. Current specimen vial labeling methods, however, are error-prone. Handwritten labels are subject to interpretation and manual data errors; labels preprinted at a central station and carried to the patient location introduce the chance for mix-ups. Mobile sample labeling eliminates these opportunities for errors, enhancing patient safety. Printing on Intermec media ensures robust traceability, meeting the application requirements of sample labeling from the point of collection through challenging laboratory conditions.

Automatic identification technologies such as bar coding excel at eliminating human error. Within the high-touch medical environment these systems have steadily improved patient safety. Errors resulting from manual data entry are unacceptable in a diagnostic environment where they can lead to lost samples (increasing time to diagnose and treat) or mistaken patient identities (potentially leading to incorrect diagnosis and course of treatment).

Recognizing the persistence of these errors, the Joint Commission on Accreditation of Healthcare Organizations (JCAHO) has made improving the accuracy of patient identification the first goal of the 2010 National Patient Safety Goals document. This goal requires blood and specimen containers to be labeled in the patient’s presence. Printing sample labels in place and on-demand with ID scanned from the patient’s wristband eliminates multiple points of error, enhancing patient safety.

Continue reading »

Wireless Printing Delivers Efficiency and Cost Savings in Retail

Wireless bar code and radio frequency identification (RFID) label printing is widely recognized by major retailers globally as an essential technology for enhancing store operations. The ability to print real-time information in the aisle, on demand, saves time, effort, and money—creating competitive advantages.

Once a retailer deploys a wireless network, the benefits of in-store wireless printing become self-evident. Employees can generate tagging labels, coupons, receipts, or tickets on demand at the point of need, and place products on promotion at a moment’s notice. Store associates can complete shelf price audits and re-labeling tasks within a short time period. Store managers can be more confident of shelf price integrity, resulting in fewer price checks at the register. Checkout clerks can print receipts as part of a mobile point-of-sale or customer line-busting solution. In addition, item-level RFID tagging enables precise inventory management and improves store efficiency.

Wireless printers, especially handheld mobile printers, can help lower total in-store printing expenses, reduce total cost of ownership (TCO), improve labor productivity, boost return on investment (ROI), and increase customer satisfaction. The pages that follow detail the far-ranging benefits of wireless bar code and RFID printing, and present innovative wireless printing solutions from Zebra.

Continue reading »

Zebra QLn Series Mobile Label Printers

Zebra’s popular QL family of direct thermal mobile label printers has built a highly satisfied following based upon its proven drop-resistant durability; user-friendly, productivity-boosting features; and easy integration. As Zebra’s third generation of QL printers, the QLn series extends these QL-platform benefits to the “nth†power—whether you choose the QLn320 for 3-inch-wide printing, or the soon-to-come 2-inch QLn220 printer.

A new seamless, one-piece design and tempered-glass display join the printer’s rubber-infused over-molding to make the lightweight printer even more durable. The QLn printer can boost your operation’s productivity through a larger, sharper, easier-to-navigate display; faster, higher-quality printing; a variety of proactive alerts that help keep working printers in employees’ hands; and many convenient charging accessories. And your IT department will find the QLn easier to integrate into existing environments with such features as Zebra Global Printing (coming soon), improved network performance, and ZebraLink support. Also prolong printer uptime and enhance operations productivity with remote Ethernet- connected printer, battery, configuration, and firmware management, all supported by ZebraLink tools.

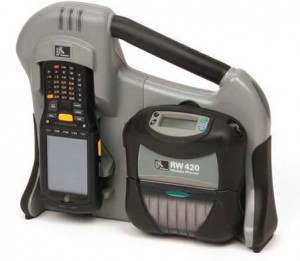

Zebra RW 420 Route Palette integrates Motorola’s MC9500 Series Mobile Computers

Zebra announces the release of their next version of rugged RW 420 Route Palette. This integrated carrying device is designed to work specifically with Motorola’s new MC9500 industrial grade mobile handheld computer. Ideal for route accounting, direct store delivery or field service and sales operations, the RW 420 brings efficiency and ease-of-use to field mobility applications, saving valuable time and money.

Zebra announces the release of their next version of rugged RW 420 Route Palette. This integrated carrying device is designed to work specifically with Motorola’s new MC9500 industrial grade mobile handheld computer. Ideal for route accounting, direct store delivery or field service and sales operations, the RW 420 brings efficiency and ease-of-use to field mobility applications, saving valuable time and money.

Designed to handle the harsh demands of mobile computing in the field, the RW 420 Route Palette is the most rugged of its kind, with an Ingress Protection (IP) rating of IP 42, making it resistant to certain environmental conditions, such as moisture, dust and dirt.

Mobile Printing Requirements for Direct Store Delivery (DSD) Applications

Selecting the best available mobile printer for the direct-store-delivery (DSD) application is as critical as the mobile computer selection.

Rugged mobile thermal printers’ benefits over impact technology are significant and include:

- Smaller, more portable footprint

- Ease of use

- Reliability

- Total cost of ownership

- Battery life

By David Krebs, VDC Research Analyst

Direct store delivery (DSD) is a key method of selling and distributing products for a variety of industries and especially for high volume food and beverage products. DSD is a business process that manufacturers use to both sell and distribute goods directly to point of sale (PoS) or point of consumption (PoC) including additional product and market related services such as merchandising, surveying and data collection, campaign management or collecting competitive intelligence.

Mobile printing is increasingly central to any effective DSD solution as it saves times over manually creating invoices and allows drivers to spend more time on merchandising and sales. In addition, DSD operations leverage mobile printers to support on-demand printing of variable information and are increasingly personalizing the content for greater value add. Mobile printing solutions enable DSD drivers to create accurate updated orders, pick lists, delivery receipts, invoices, settlement reports and other documentation. In addition to the time saving benefits associated with mobile printing – printing can reduce time spent on invoicing by as much as two thirds – it also ensures increased documentation accuracy.

Small Mobile Printers Make Big Difference for Tracking Government Port Activity

When the Department of Defense (DoD) was looking for new bar code label and receipt printing solutions for a wide variety of demanding applications, Zebra Technologies clearly stood out from its competitors. Zebra’s line of rugged, mobile, and easy-to-use printers and accessories provided the speed, power, and durability that the DoD’s various agencies needed.

One of the agencies currently using Zebra® printers is the Virginia-based Military Traffic Management Command (MTMC), which provides worldwide single-port management, transportation and traffic-management services, and deployment planning and engineering for the DoD.

MTMC has used the Worldwide Port System (WPS) to account for military cargo being shipped around the world through water ports. This Automated Information System(AIS) supports MTMC units operating in both domestic and overseas water terminals.

An early proponent of the use of bar coded labels, the DoD has utilized Military Shipping Labels (MSLs) to label its unit equipment being transported around the world since the mid-1980s. The label included a linear bar coded Transportation Control Number, which functioned as the number by which cargo is tracked. Labels were scanned when cargo arrived at or left one of MTMC’s water ports, or when it was lifted or discharged from a military-owned or leased ship. Although this was an improvement over a totally manual process, scanning linear bar coded labels still required significant human resources to track and manage cargo coming in and out of its ports around the world.

How Mobile Printing Benefits Warehouse Operations

Executive Summary

To maintain accuracy and efficiency in warehouses and distribution centers, bar coding and radio frequency identification (RFID) systems are indispensable. Businesses can enhance these benefits by using mobile printers to produce and attach bar code and RFID labels at the point of application. Supplementing stationary bar code and RFID printing operations with mobile printers can reduce operator errors, streamline operations associated with labeling in inconvenient locations, and eliminate costs associated with correcting errors.

Using mobile printers to eliminate the distance that workers travel to pick up labels can boost productivity, often providing a full return on investment (ROI) in less than a year when used in warehouse, distribution center, and other industrial environments. The ROI is especially strong for facilities with existing wireless LANs, because a relatively small incremental investment in mobile printers creates new ways to increase efficiency, reduce operator errors, and leverage the wireless infrastructure investment.

RFID is an automatic identification technology that relies on radio frequency (RF) waves to read encoded digital data. RFID is similar to bar code technology in concept. Unlike a bar code, RFID does not require a visible tag or label to read its stored data.

This white paper shows where it makes sense to supplement bar code and RFID labeling operations with wireless and/or mobile printers by:

-

- Identifying common operating procedures in warehouses and distribution centers that mobile/wireless printing can improve.

- Illustrating how businesses can prevent common operator labeling errors by printing at the point of activity.

- Providing real-world examples of how mobile printing systems have improved operations.

- Presenting formulas and guidance for creating an ROI calculation.

- Describing how mobile printers can be integrated with wireless LANs and batch operating systems.

- Presenting an overview of mobile printing technology and capabilities.

Datamax-O’Neil’s Microflash 4t printer Makes NYPD Parking Citations More Accurate and Efficient

Cautionary words to those who park in New York City— obey the rules, or pay the price. A computerized parking citation system rolling out to the NYPD’s parking enforcement division will effectively eliminate hand-written traffic tickets. The result: a more accurate, efficient and cost effective solution. City officials say the new system will significantly reduce errors associated with hand-written tickets and, according to some estimates; realize millions in unpaid fines owed the city.

The solution consists of Symbol Technologies’ handheld computer, the PPT 2800, and Datamax-O’Neil’s portable Microflash 4t thermal printer. The terminal’s pocket PC platform and features, including bar code scanning and real-time wireless communications, allow officers to scan vehicle registration stickers, print tickets, and upload the information to a central database.

The solution works well in New York City, as New York State requires that all vehicles have their registration affixed to the inside of the windshield. The registration includes a 2-D barcode, which the parking officer scans using the handheld computer, and information about the vehicle is instantly and accurately captured. A traffic summons is printed on the spot by the wearable thermal printer, which is connected to the PC via a wireless LAN.

Zebra RW 420 Takes the Cake in Head-to-Head Printer Comparison at Tastykake

About Tastykake

In 1914, a baker and egg salesman decided to join together to produce baked goods with the freshest ingredients. When the baker’s wife deemed the results of their efforts “tasty,†Tastykake was born. Now, the Philadelphia-based company sells more than $250 million worth of cakes and pies annually across the East Coast.

Challenge

With nearly 500 delivery routes, Tastykake brings fresh baked goods to hundreds of stores every day. The faster that drivers can restock each location, the more stops they can make in a day.

Drivers use Motorola® MC9000 handheld mobile computers to log the inventory coming off and onto store shelves. As they bring in new products, they print out invoices for each store on printers back in their trucks.

In an effort to improve efficiency, reduce costs, and add new capabilities, Tastykake began looking at new mobile printers.