The Value of RFID in Inventory Management & Supply Chain Visibility

Radio Frequency Identification (RFID) is revolutionizing inventory management and supply chain visibility. While barcodes have been the dominant tool for item identification for decades, RFID offers a powerful alternative with advantages like real-time tracking, non-line-of-sight reading, and faster automation. Although RFID implementation requires more planning and investment than barcoding, it can provide significant efficiency gains for businesses seeking to streamline operations and reduce errors.

Why RFID is Worth Considering

To determine if RFID is the right fit for your business, it’s important to evaluate your needs and operational challenges. Unlike barcodes, RFID does not require line-of-sight to read tags, which makes it ideal for tracking items moving through conveyor systems or stored in hard-to-see locations. The technology also supports varied read ranges, from a few inches to over 10 feet, depending on the tag and reader setup. RFID can be particularly effective when items are traveling at high speeds or are fixed at certain checkpoints.

However, environmental factors must be considered. Items containing metal or liquids can interfere with RFID signals, impacting system performance. Similarly, the choice of fixed or mobile readers depends on whether you need automated scanning at warehouse entry points or manual inventory checks on the move.

Types of RFID Technologies

RFID operates in three main frequency ranges. Low Frequency (LF) systems work well for close-contact applications like ID badges or access control, but their range is limited to a couple of inches. High Frequency (HF) systems can read tags up to 3 feet away, making them ideal for small item tracking and applications like healthcare equipment management.

For supply chain and inventory purposes, Ultra High Frequency (UHF) is the most widely adopted RFID solution. UHF systems offer extended read ranges of up to 10 feet, making them highly effective for item-level and container-level tracking. UHF’s affordability and flexibility have made it a popular choice for businesses looking to manage large volumes of inventory efficiently.

RFID tags are also classified as active or passive. Active RFID tags have their own battery power, enabling long-range and high-speed scanning, but they are costly and bulky. Passive tags, on the other hand, rely on the reader’s signal for power, making them thinner, more affordable, and ideal for product-level tracking in inventory systems.

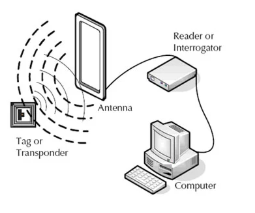

How RFID Works

A typical RFID system includes four key components: tags, antennas, readers, and host software. When a passive RFID tag enters the signal field of an antenna, the tag receives power from the reader. It then “backscatters” its stored data, which is captured by the antenna and processed by the host software. Unlike barcodes, RFID tags can be read even if they are not in direct view or perfectly oriented, enabling faster and more efficient inventory tracking.

The host software uses the captured data for applications such as asset tracking, inventory control, or logistics management. For example, fixed RFID readers can monitor inventory as it passes through warehouse doors, while mobile readers allow employees to conduct manual counts while on the move. Desktop RFID readers offer a plug-and-play option for situations that require reading tags next to a PC, such as retail checkouts or quality control stations.

Challenges and Limitations

While RFID is highly effective, it is not without limitations. Environmental factors such as metals and liquids can interfere with signals, reducing accuracy. Dense collections of items may also pose challenges, as tags in the center may not receive enough signal power to activate. These factors require extensive testing and system design to achieve optimal results.

Additionally, RFID systems involve higher upfront costs compared to barcode solutions. However, businesses that plan carefully and implement RFID effectively often achieve significant long-term savings through reduced errors, improved accuracy, and labor efficiency.

Components of an RFID System

An RFID system begins with the selection of the right tags, which are designed with a combination of chipsets and antennas to store and transmit data. The choice of tags depends on the environment, product type, and read requirements. For high-volume applications, RFID printers simplify the process by encoding tags and printing barcodes as a backup, ensuring data accessibility even if the RFID tag is damaged.

The RFID readers themselves come in various forms. Fixed readers are ideal for automated scanning at checkpoints, such as warehouse docks or conveyor lines. Mobile readers, which resemble handheld computers, are versatile tools for conducting inventory counts and asset tracking across facilities. Desktop readers, though limited in range, offer quick and easy data capture for localized applications.

Finally, middleware software ties the system together. Unlike barcode scanners, RFID readers do not output basic text data directly. Instead, middleware processes the RFID data and integrates it with inventory management or enterprise software. Systems supporting Low Level Reader Protocol (LLRP) ensure compatibility with most RFID readers.

The Benefits of RFID in Supply Chain Management

The greatest value of RFID lies in its ability to enhance efficiency, accuracy, and automation. It enables businesses to track inventory in real time without requiring manual scanning. By reading multiple tags simultaneously, RFID reduces the time and labor involved in inventory checks. Its non-line-of-sight capability allows for greater flexibility, especially in environments where items are stacked, moving, or difficult to access.

Conclusion

RFID technology is transforming the way businesses manage inventory and supply chains by offering faster, more accurate, and automated tracking solutions. While the technology presents challenges, such as signal interference and higher initial costs, the benefits far outweigh these limitations when implemented correctly.

For businesses exploring RFID, it is best to start with a small-scale pilot project, test its feasibility, and gradually scale up. With careful planning and the right resources, RFID can provide unparalleled visibility and efficiency in your inventory management processes, giving you a significant edge in a competitive market.