Thermal based barcode printers provide a very economical way to create high quality labels, tags, wristbands, receipts, and tickets. Compared to other printing technologies, thermal-based options require less maintenance, have less expensive media, and print faster while maintaining excellent print quality.

Since these types of printers are different from your typical laser or inkjet printers, it can be a challenge to know which one will fit your business best. The first step in finding the right printer is to identify your specific need(s):

- How many labels do you need to print?

- Where will the printer be used?

- What type of environment will the printer be used in?

- What type of environment will the labels be used in?

- How rugged or durable does the printer need to be?

- What type of material is needed to be printed on?

- How often do you need to print?

- Does your printer need to connect to other printers or networks?

- Will the printer need to be fixed or mobile?

Knowing how you’ll be using a printer will help you decide what type, print method, and other features you’ll need. Understanding and going through the following features will help you determine the best printer for your needs.

Types of Barcode Printers

Thermal Label Barcode Printers

Thermal Label printers may sometimes be referred to simply as “label” printers, but offer the most flexibility of our printing options. Most solutions requiring a thermal label printer require the production of barcodes on labels, but these printers also have the ability to print on multiple substrates, including tags and wristbands. However, all thermal label printers are not the same. You will need to carefully consider all variations within the category including but not limited to: lifespan of the label being produced, estimated print volume, where the printing needs to take place, and any specializations needed . The following sections provide some guidance on varieties within the Thermal label printing category:

Lifespan of Label

Thermal printers are capable of printing in 2 different ways – direct thermal (DT) and thermal transfer (TT). The type of technology required for your printing solution is based on the environment and the required longevity of the label.

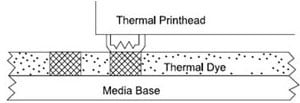

Direct Thermal Printers

For short durations (under a few days and not in rugged environments), a direct thermal label printer may be the proper fit. Direct thermal labels are suitable for short-term applications where the labels will not be exposed to excessive heat, light, or abrasion. Direct thermal printers utilize heat-sensitive media that blackens as it passes under the printhead. Because they print without a ribbon, direct thermal printers are noted for their simplicity. The heat-sensitive coating can fade over time when exposed to sunlight, high temperatures, or contact with certain chemicals. Direct thermal labels have a limited lifespan compared to thermal transfer labels. The heat-sensitive coating can degrade over time, causing the print to fade or become illegible, especially in harsh environmental conditions. Direct thermal labels are commonly used for applications such as shipping labels, barcode labels, receipts, tickets, and temporary signage.

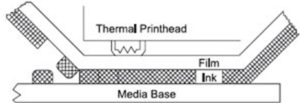

Thermal Transfer Label Printers

If your solutions requires a more durable and longer lasting label, thermal transfer printers are your best option. Unlike direct thermal labels, thermal transfer labels require the use of a thermal transfer ribbon to transfer ink onto the label material, through the use of heat. Thermal transfer labels are available in a wide range of label materials, including paper, synthetic materials (e.g., polyester, polypropylene). Thermal transfer labels offer superior durability and resistance to environmental factors compared to direct thermal labels. The thermal transfer printing process creates permanent, high-quality images that are resistant to fading, smudging, and abrasion, making them suitable for long-term labeling applications. Thermal transfer labels are commonly used for a wide range of applications, including product labeling, asset tracking, inventory management, barcode labeling, compliance labeling, and outdoor signage. While thermal transfer labels offer superior durability and print quality compared to direct thermal labels, they also require the additional cost of thermal transfer ribbons. However, the overall cost of ownership may still be lower compared to other printing technologies due to the longevity and reliability of thermal transfer labels.

Print Volumes

The type of printer you choose may also be impacted by the number of labels you plan to produce. Smaller label volumes tend to gravitate towards desktop printers, while larger volumes are better suited for Industrial printers.

Desktop

This type of printer is made for small volume applications that are making fewer than 500 labels per week on average. Desktop barcode label printers are typically small and lightweight, making them ideal for use in office environments, small businesses, and retail settings where space may be limited. Printers like the AirTrack DP-1, Zebra ZD421, and Honeywell PC45 still produce the same quality and wide range of media as bigger printers, just at a smaller volume. Desktop printers typically hold smaller amounts of labels than industrial printers, which require more frequent changes of label and ribbon media.

Industrial

Industrial barcode label printers are larger and more rugged than desktop models for high volume print applications. From a couple thousand labels per day to printing all day long, these printers are designed to hold more media which allow for less downtime in your printing production. Industrial printers also offer more flexibility in print media sizes, allowing for printing from .5″ to over 8″ wide. Industrial printers are typically used in Manufacturing, Distribution and Logistics, retail and Healthcare verticals. Many industrial barcode label printers feature advanced management and monitoring capabilities, including remote printer management software and web-based interfaces. These tools enable administrators to monitor printer status, configure settings, and troubleshoot issues remotely. You’ll find printers like the Airtrack IP-2A, Zebra ZT411, and Sato CL4NX Plus in manufacturing and distribution centers as well as large retailers. If you are printing any type of media in large volumes, industrial label printers are your most reliable option.

Stationary vs. Mobile

Many applications require the print and application in one stationary area, which allows for use of a stationary barcode label printer. However, when your product requires labeling at different points through a facility or trying to label something outside the four walls, a mobile option may be a better fit.

Mobile

Mobile barcode label printers are similar to thermal barcode label printers but provide freedom from any cable connections to a PC. Mobile printers do have a few limitations due to their small size. They are not made for very high volumes, have limited roll capacity, and have smaller print widths, usually 2″, 3″, or 4″ max. However, if you need to make labels or receipts on the move, a mobile printer will provide you high quality print in a compact package that fits on your hip. These printers are perfect for delivery drivers or sales agents to create receipts in the field or a warehouse worker that needs to make labels on the spot. Since these printers are not tied to a fixed PC, you normally communicate to them wirelessly through Bluetooth or Wi-Fi. Pair a mobile printer like the Zebra ZQ 620 Plus and TSC Alpha 30L with a laptop, mobile computer, or smartphone for printing wherever you go!

Mobile Carts

If you don’t require a truly mobile version or the limitations of the mobile media are sub-optimal for your solution, a hybrid option is a mobile cart. Barcode label mobile carts, also known as mobile labeling stations or labeling carts, are portable workstations equipped with barcode label printers, computers or mobile devices, and storage compartments for label stock, ribbons, and other supplies. These carts are designed to streamline the labeling process by allowing users to print labels on-demand and apply them directly to items or locations as needed. Mobile carts come with options for battery powered, which can extend the amount of time your printer can be used on the go. Solutions like the Newcastle NB Series and DTG Lithium Battery Powered Carts are used in a wide range of industries and applications where on-demand labeling is required. Common applications include inventory management, asset tracking, shipping and receiving, manufacturing, healthcare, retail, and warehouse operations.

Specialty Media

While some industrial printers provide the utmost flexibility to print on all media types, sometimes media specific printers are required. Purpose built for a specific solution, the options included in these printers provide a focused approach on the solution at hand.

Wristband

Even though standard label printers can also create wristbands, a dedicated wristband printer offers several advantages and a lower overall cost. For applications that are making wristbands every day like hospitals, theme parks, and concert venues, a dedicated wristband printer is the perfect fit. While other printers have their media on a roll, wristband printers have cartridges that simply drop into place to keep you printing with almost no downtime. These printers also have a higher print resolution standard for clear, accurate printing of images or logos. Added to this, most models have a special anti-microbial case to meet the demands of any healthcare environment. If you need custom printed wristbands on a regular basis, a dedicated wristband printer like the Honeywell EasyCoder PC23d and Zebra ZD510-HC will be the most efficient and easiest to use solution.

Ticket

Ticket printers are another specialized thermal printer that excels at printing on thicker paper for ticketing applications. If you are making tickets for concerts, festivals, or any other type of event, a dedicated printer will help you make them faster with less hassle. Since most tickets come in a fan-folded stack instead of rolls, these printers have a taller case to accommodate more stacked media. They can also still use roll media but with a larger stack of tickets you will spend less time reloading the printer. These printers also have an opening on the back of the case to easily feed ticket stock externally. Models like the Printronix T8000 are a high performance option for demanding ticketing applications.

Integrated Add-Ons

After you’ve narrowed down the type of printer and how you will print with it, the last step in finding the right printer is determining what add-on accessories you might need. Many print applications may not even need any of these options, but they can also be what make a specific printer an indispensable tool for your business. Most of these options are only available on desktop or industrial printers, though specific add-ons will vary by model.

Cutter

A cutter does exactly what it is named. As the label is printed the cutter will separate the single label from the roll it is attached to. Most label stock is perforated already so it is easy to tear it off the printer but when you are using continuous or special media a cutter is essential.

Rewinder

A rewinder is an internal roller that allows you to print labels and have them feed back into the printer onto a new roll. This option is especially useful for high volume applications that are printing large batches at one time. With a rewinder you end up with a roll of printed labels as opposed to a pile of labels in front of your printer

Peeler/Dispenser

This option takes each label as it is printed and separates it from the backing liner. Peelers are perfect for applications that are printing individual labels and then applying them to a product immediately. It saves time from having to tear off the label and then peel it. However, if you print in batches this is not a good option since the printer stops printing until you remove it from the printer after it has been peeled.

RFID

Some printers, including a few mobile units, offer options for making RFID based labels. With this option, you can print on the front of a label while encoding information into the RFID chip on the back of the label. RFID printer options vary depending on what frequency range you will be working at and most printers will support UHF or HF ranges. Making RFID tags can be a challenge for those not very familiar with it. Speak with one of our RFID experts to ensure you get the right printer for your RFID needs.

In-line Verifier

An in-line verifier is essentially a special type of scanner that mounts to the front of the printer. This scanner is analyzing each label that is made to ensure it meets specific print quality requirements. If a printer like the Honeywell PX940 starts to make labels below the grade you specified, the verifier will stop the printing process. When you are sending labeled products to large retailers or government/military locations, they will have strict rules on the print quality of the labels you make. The fines involved in not meeting their compliance are guaranteed to be more than the cost of the verifier. Any business that has to meet any kind of print compliance should seriously consider an in-line verifier for their printer to easily avoid the fines and headaches of poorly printed labels.

Supporting Your Printer

Printer Management

Printer Management is designed to simplify the management and control of printers within an organization’s network, including barcode label printers, mobile printers, and other types of printers used in business operations. The platform allows administrators to centrally manage all printers across the organization’s network from a single web-based console. This centralized approach enables administrators to easily deploy, configure, and monitor printers remotely, reducing the need for manual intervention and on-site maintenance. administrators can remotely configure printer settings, such as print quality, print resolution, paper size, and media type, to ensure optimal performance and consistency across all printers in the network. This helps maintain uniformity and standardization in printing operations.

True Support

Having the backstop support for your printer is also critical to ensure your operations remain at 100% uptime. TrueSupport options allow for your printer to be setup properly, and premium technical support services keep your device healthy. On-site and depot repair options as well as comprehensive coverage provide the security you need to be successful.

OEM Service Contracts

There are a wide variety of service contracts that can be applied to your printer. These contracts are designed to ensure consistent label supply, quality assurance, and support for the duration of the contract term. Service contracts may include technical support services to assist customers with label printing, troubleshooting, and maintenance. This may involve remote assistance, onsite support visits, or access to a helpdesk for resolving technical issues. In addition, contracts may include warranty provisions for defective or non-conforming labels, outlining the process for requesting replacements and the timeframe for resolving warranty claims.

Finding the Right Printer and the Right Partner

With all the options available for barcode printers today, it can be a challenge to find the right device for your business. Determining the type of printing, overall volume, and what features you need from above will make deciding on a printer easy. If you are still having difficulty or have additional questions, feel free to call our experts at Barcodesinc – we’re happy to help you find the right printer for your needs.